Why We Invested in VALIS Insights: Bringing Circularity to the Metals Processing Industry

March 18, 2024

This blog is part of our “Why We Invested” series, which offers a deep dive into our most recent investments and the growing circularity trends in the space.

The way scrap metal is processed today is a mystery to most outside the industry. When a car or an appliance reaches the end of its useful life, most of us often rely on a junk removal service––or hope that the retailer selling the new equipment will take the old one with them on the way out. What happens after that?

Emily Molstad, Caleb Ralphs and their team at VALIS Insights have spent the past five years getting to know these markets in minute detail. Imagine spending days and nights captivated by how metals are processed in the U.S. after they’re done being used. Imagine coming face-to-face with the information asymmetries in the system that result in mixed metals being shipped overseas instead of recovered for local use. Imagine having hundreds of conversations with processors, metals refiners and customers of virgin and recycled metals to better understand why the system is built the way it is and where there are opportunities to improve it. That’s what this team has done so comprehensively over the past few years, driving toward the creation of their AI-powered software that is closing the loop on a circular economy for metal fabrication.

Today, used metals are still dramatically under-recovered in the U.S. Recycling rates for many non-ferrous and ferrous metals lag below 60%, despite the high resale value of these materials. As of the latest data from the EPA, only 27.8% of ferrous metals (those containing iron) were recycled in 2018––and nearly 7.2% of all municipal solid waste landfilled in 2018 was from steel––equivalent to 10.5M tons. The reality is often worse for non-ferrous metals (such as aluminum, copper, nickel) which may only be sorted for recycling after their heavier ferrous counterparts are removed.

These insufficient recycling rates for metals can be attributed to losses during material processing. Current recycling technology and processing capabilities struggle to address the growing complexity of mixed metal products, leading to contaminated and downgraded metal recovery. Scrap processors have historically recovered only certain metal commodities that were perceived to have higher resale value, leaving out other various mixed metals from the sorting process and shipping them overseas. As a result, significant volumes of aluminum, copper, nickel and cobalt are lost from our domestic supply. However, increasing domestic demand in the U.S. is driving up value for these types of materials, and tools like VALIS’s solution help scrap processors understand the monetary value of the metals they are currently selling overseas.

Closed Loop Partners has long understood the complexities of end-of-life commodity markets––we’ve been investing in the space for a decade and recognize that challenges exist at every stage in the value chain––collection, sorting, resale and ultimately recovery into the next life. For large format composite metals––such as automotive, appliances and heavy machinery––collection has rarely been a problem. These products are bulky enough that they typically end up in processing facilities around the country. The challenge is what happens after that.

We invested in VALIS because their software improves the sorting process of mixed metals and allows domestic processors to maximize the resale value of the outputs, keeping more metals in local circulation. By capturing data on commodity prices and input materials and delivering high-value insights on material and processing trends, they help optimize sortation processes to capture the most valuable metals that might otherwise be overlooked. With more optimized and predictable sortation, processors can command higher prices for higher quality outputs.

As the U.S. faces an extreme shortage of critical metals that are required for the renewable energy transition, solutions like this are increasingly important. Copper, nickel, aluminum, graphite and steel among others are seen as critical and are expected to be in . Many companies have now mandated chain-of-custody and fair labor validation of the minerals and metals used within their supply chains. VALIS helps create lower cost, resilient and transparent supply chains for these metals domestically––and focuses on metal recovery from current waste streams rather than incremental extraction. This provides multiple benefits including reducing waste, enhancing local economies and lowering the emissions footprint of the recycled metals.

Overall, VALIS helps recover more pure metals from our existing waste streams, reduces the complexity of the end products that are being sold for the next stage of processing and can help get metals back in circulation faster. They do all of this, while providing the traceability that’s so essential in today’s critical mineral supply chains. VALIS is improving the business case for scrap processors today, while creating new opportunities for greater material recovery from the urban mine. It makes economic sense. It makes emissions sense. And yes, it makes material sense. That’s the circular economy.

About Closed Loop Ventures Group at Closed Loop Partners

Closed Loop Partners is at the forefront of building the circular economy. The company is comprised of three key business segments: its investment arm, Closed Loop Capital Management; its innovation center, the Center for the Circular Economy; and its operating group, Circular Services. Closed Loop Capital Management manages venture capital, buyout private equity and catalytic private credit investment strategies. The firm’s venture capital group, the Closed Loop Ventures Group, has been investing early-stage capital into companies developing breakthrough solutions for the circular economy since 2016. The Closed Loop Ventures Group’s portfolio includes companies developing leading innovations in material science, robotics, agritech, sustainable consumer products and advanced technologies that further the circular economy. Closed Loop Partners is based in New York City and is a registered B Corp. Closedlooppartners.com.

About VALIS Insights

VALIS Insights is building AI-powered software that makes recycling more profitable, material supply chains more sustainable and closes the loop on a circular economy for metal fabrication. With VALIS technology metal recyclers gain visibility into their material quality and make data-driven process decisions to extract more value. Founded in 2022 by experts in metal recycling and data science, VALIS is dedicated to delivering the software and data solutions needed across the recycling value chain to ensure the materials of yesterday are properly recovered for the manufacturing of tomorrow. For more information visit https://www.valisinsights.com/.

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Partners or any company in which Closed Loop Partners or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Information provided reflects Closed Loop Partners’ views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision.

Related posts

Blog Post

Why We Invested in Mycocycle: Nature-Inspired Circular...

Closed Loop Partners’ Ventures Group saw a key opportunity...

Press Release

Closed Loop Partners Leads $4M Seed Round for LAIIER,...

Investment in the innovative liquid leak detection...

Blog Post

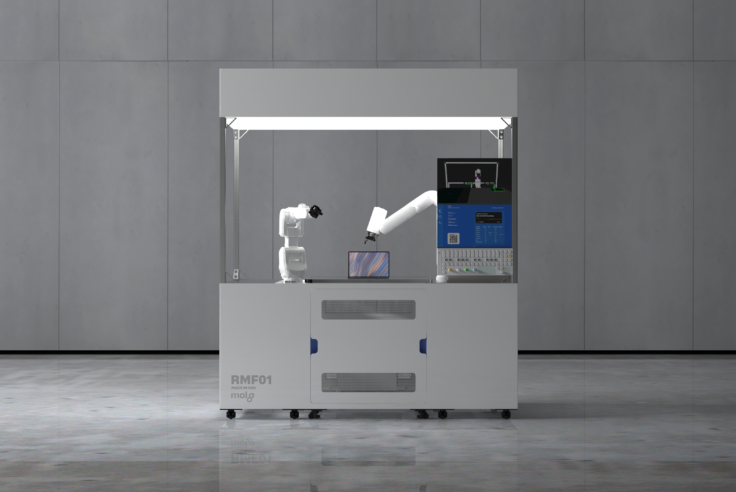

Making Circularity Stick: Electronics

A conversation with Rob Lawson-Shanks, CEO of Molg...

Press Release

Closed Loop Partners Doubles Down on Investment in...

Closed Loop Ventures Group joins Earthodic's $4 million...

Blog Post

Why We Invested in Neutreeno: Engineering Circular...

Neutreeno offers a game-changing solution that seamlessly...

Press Release

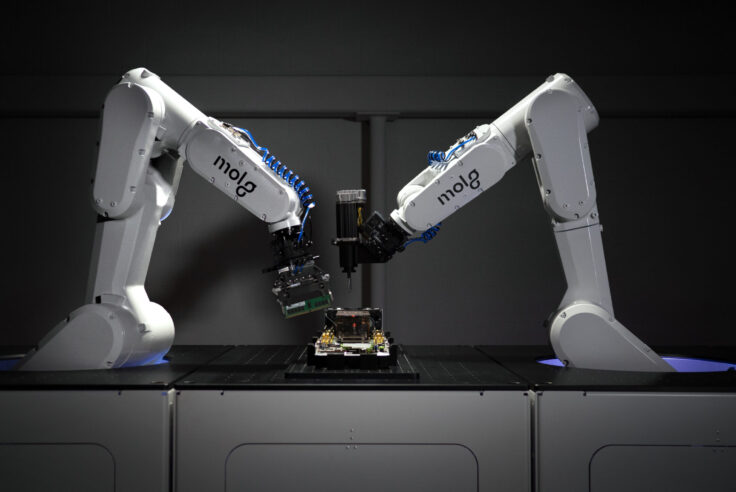

Molg Raises $5.5 Million in Seed Funding to Tackle...

Closed Loop Partners' Ventures Group leads seed funding...

Blog Post

How the Apparel Industry Is Challenging Us to Think...

The high cost of textile waste has sparked the need...

Blog Post

Why We Invested in Aerflo: Making Reuse an Everyday...

Closed Loop Ventures Group is thrilled to announce...

Blog Post

Why We Invested in Capra Biosciences: How Microbes...

Today, we are witness to a rapidly changing manufacturing...

Blog Post

Why We Invested in Found Energy: The Importance of...

Closed Loop Ventures Group invests in Found Energy,...

Blog Post

Why We Invested in Molg: Supporting the Circular Economy...

Closed Loop Ventures Group shares how Molg Inc. is...

Blog Post

Putting Recovery at the Center of the Critical Minerals...

At Closed Loop Partners, we see significant opportunity...