The Key to a Strong Local Economy? It Must Be Circular.

January 08, 2025

4 ways the circular economy unlocks local value.

“We are entering the era of the local, circular economy.”

Localization––of industries, supply chains and jobs––is gaining momentum in cities and states across the country. Spurred by increased global trade pressures, pandemic-induced bottlenecks, intensifying climate impacts and increasingly volatile trade routes, a renewed call for local supply chains has emerged.

These appeals have permeated both business and policy: economic regulations increasingly prioritize local goods and production, while ‘Made in America’ initiatives are championed by major corporations like Walmart and Amazon and incentivized by the federal government.

The motivation is clear as the benefits of localization are manifold: when local communities are empowered with ownership of the goods and materials they consume, they reap economic, environmental and social rewards.

For us at Closed Loop Partners, a decade of investing, innovating and building solutions for a waste-free world has taught us the key to a successful local economy: it must be circular.

Lessons from 10 years of local, closed loop initiatives

From its inception, Closed Loop Partners recognized that a circular economy—a system that eliminates waste, recirculates goods and materials, and regenerates nature—goes hand-in-hand with localization.

Graphic by: Closed Loop Partners

Graphic by: Closed Loop Partners

This vision first came to life when we launched our Closed Loop Infrastructure investment strategy 10 years ago. Leveraging catalytic funding from several of the world’s largest corporations, Closed Loop Partners invested in recycling infrastructure within local municipalities, keeping material out of landfills across the country.

Today, our work has expanded to embody the fullness of circularity, supporting solutions that infuse circularity not only in how we handle waste, but in how we create and maintain goods––through redesigning, remanufacturing, reusing and repairing––with a commitment to localization woven throughout.

“Local supply chains offer smaller, more efficient material loops that avoid leakage, waste and emissions-intensive transportation.”

The more local each stage of production, the more value is shared within local communities, enabling an incentive structure to keep products at their highest and best use for multiple lives.

If we prioritize local circularity and reverse the status quo of long, inefficient and expensive supply chains, the benefits are undeniable.

Here are four outsized impacts that local circularity can unlock:

1) Grow Local Wealth

From designers and engineers to manufacturers and business owners, circularity creates meaningful jobs and economic opportunities in remanufacturing, recommerce, reuse, repair and recycling. It’s estimated that transitioning from today’s linear economy to a circular economy would net 7 to 8 million jobs globally by 2030, many of which are inherently place-based in local manufacturing, repair, reuse and recycling sectors. In the U.S., green jobs are expected to expand to nearly 24 million, comprising 14% of total U.S. jobs by 2030.

In addition to job creation, circularity keeps the value of materials, goods and services in local communities. One such example can be found in our electronics value chain: in lieu of importing raw materials, manufactured electronics and e-waste, a transition to repairing, reselling and disassembling electronics locally keeps valuable metals and minerals within the U.S. production sector. In North America, over 7 metric tons of e-waste are generated per capita––a circular electronics value chain in the region could bring over $8 billion in value back to communities.

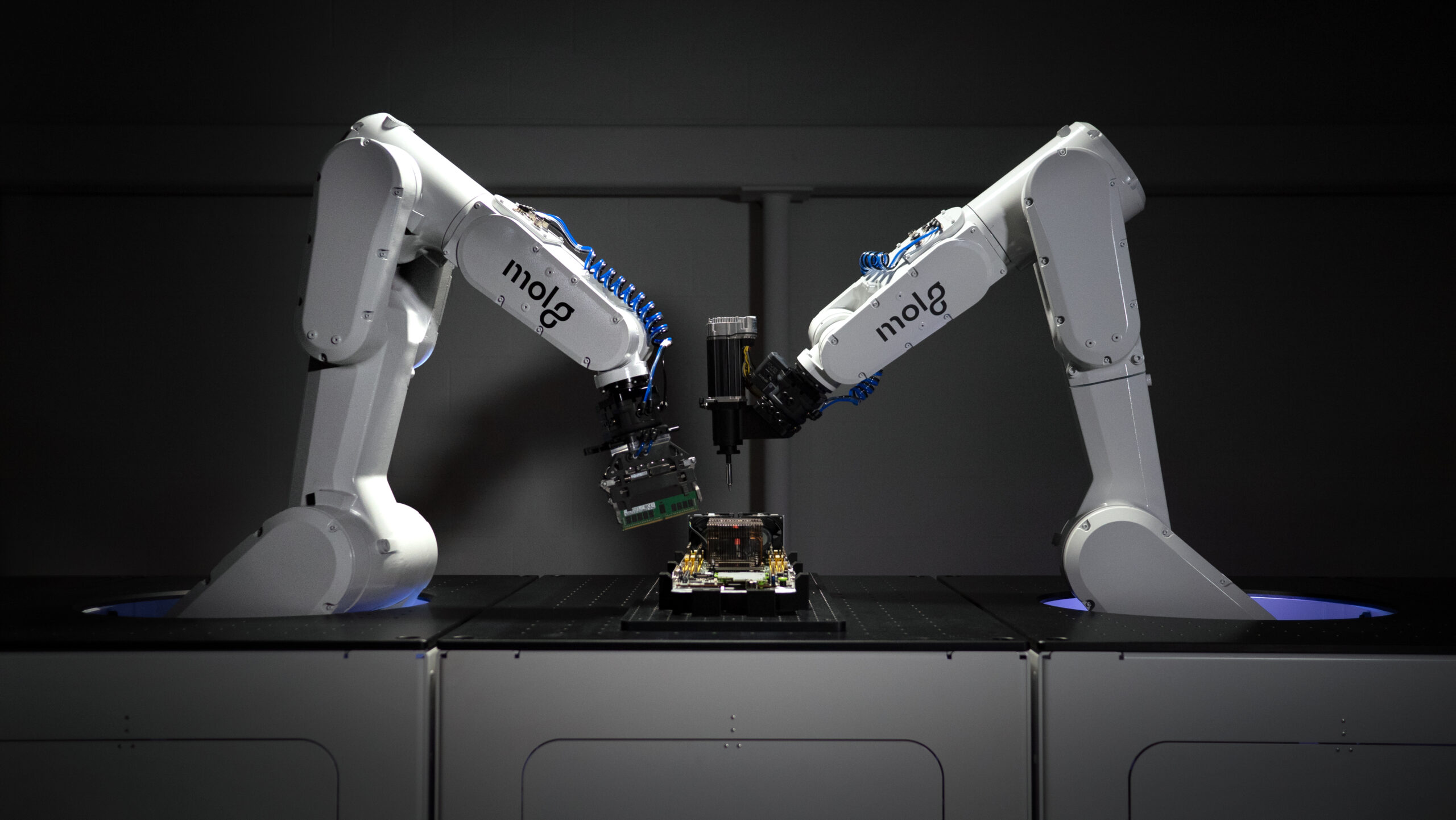

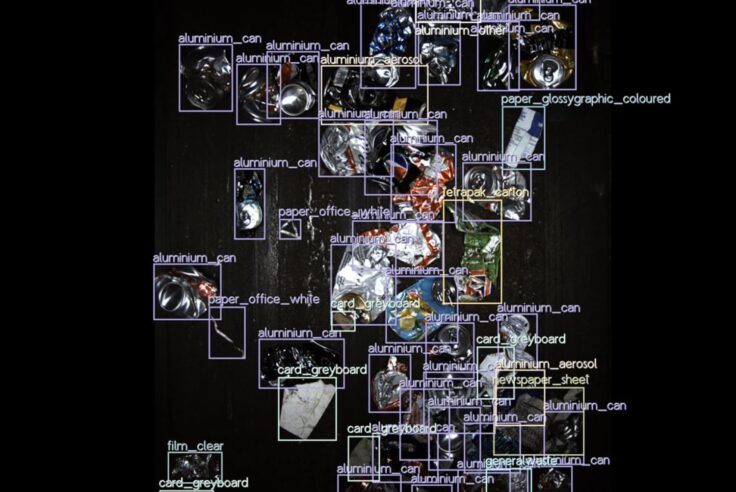

One example of a solution to keep more electronics in circulation is Molg, a portfolio company of Closed Loop Partners that’s capturing valuable components and materials from discarded enterprise electronics in Microfactories across the U.S. By disassembling locally, Molg keeps these materials out of landfill while supporting the local economy and job creation—enabling local remanufacturing and resale while reducing the need for imported resources. Molg’s technology is designed to enable cost-effective recovery of components and materials—reducing waste, boosting supply chain resilience and ensuring that valuable resources are recovered for future use.

Photo credit: Molg

Photo credit: Molg

2) Reduce Costs (and Emissions)

Beyond value creation, local circularity reduces the economic and environmental costs associated with long, inefficient supply chains. As our economy has globalized, goods and materials traverse an ever-expanding number of transportation nodes that incur unnecessary expenses and emissions.

Consider that 80 percent of the emissions associated with the consumption of goods and services in C40 cities came from goods and services that were imported. To reverse this trend, new circular businesses are working to localize recycling and remanufacturing of critical materials.

One such example is Circular Services, a Closed Loop Partners company and the largest privately held recycling company in the U.S., serving municipalities and commercial properties in some of the nation’s largest and fastest growing cities. Through its network of Circular Resource Facilities, Circular Services collects and processes valuable commodities––including paper, metals, glass, plastics, organics, textiles and electronics––keeping valuable materials in local circulation and improving regional economic and environmental outcomes in the communities in which it operates.

By employing innovative technology within reuse, recycling, remanufacturing and recommerce, resources that were once sent across the country or across the world at end-of-life are now processed locally within Circular Services’ facilities, helping return more materials to supply chains of major consumer brands for continued use at their highest possible value. In 2023, Circular Services put over 1 million tons of materials back into production supply chains, keeping these materials out of landfills, avoiding over 1.6 million metric tons of emissions and saving government and business the cost of landfilling goods.

3) Build Agility (and Resilience)

Long supply chains are inherently rigid and slow to adapt. By shifting towards more local, circular supply chains, we can build shorter, malleable material flows that can more easily respond to changes and disruptions. This also reduces reliance on goods and resources that are located across the world and need to travel long distances through complex supply chains.

With the steady rise of online shopping, the reverse logistics of e-commerce returns is a prime example of a long, complex supply chain rife with silos and inefficiencies. Fillogic, a Closed Loop Partners portfolio company, is reimagining these logistics to bring them closer to home.

Photo credit: Fillogic

Photo credit: Fillogic

By repurposing under-utilized spaces at shopping malls and strip centers into local logistics hubs, Fillogic activates a network of local retailers and customers, adapting to local needs and conditions. Their technology intercepts unsold garments at the middle mile and redirects them to the appropriate channels for resale. Fillogic provides a complete reverse logistics solution that supports returns, resale, trade in and recycling. By keeping this process local, they avoid sending products through inefficient legacy supply chains—where they traditionally end up as waste—while allowing retailers to adapt to local supply and demand with speed and agility. In 2024 alone, Fillogic kept over 500 million tons of materials in circulation (a 500% increase over 2022), avoiding over 500 million tons of greenhouse gas emissions.

Photo credit: Fillogic

Photo credit: Fillogic

4) Create Pride

Finally, circularity can foster a sense of pride in local communities. A product that is made and sold locally offers a tangible connection to community and place. A product or service that is remade, resold and that recirculates value locally perpetuates that community connection throughout each of its uses and lifetimes––all while fostering communal responsibility in keeping products out of landfills and the natural environment.

A powerful example of this is the Petaluma Reusable Cup Project in California, led by the NextGen Consortium, an industry collaboration managed by Closed Loop Partners’ Center for the Circular Economy. As a first-of-its-kind initiative, the project made reusable cups the default option in more than 30 restaurants in the City of Petaluma. Consumers were invited to use, return and reuse iconic purple containers in place of disposable, single-use alternatives.

Photo credit: Kellyann Petry

Photo credit: Kellyann Petry

Engaging national brands alongside local establishments and consumers, the project united a network of community members and institutions, inviting shared ownership in reducing local waste, supporting local businesses and maintaining local value. While we are still collecting and analyzing data, the level of community engagement achieved is demonstrated in early findings from the project: over 220,000 cups were returned, ~80% of the Petaluma residents surveyed were aware of the program, and 90%+ of the Petaluma residents surveyed had a very good, good or neutral experience with the program––demonstrating the power of strong, local initiatives.

Photo credit: Kellyann Petry

Photo credit: Kellyann Petry

Opportunities Ahead

As we reflect on our 10 years of work at Closed Loop Partners, one thing is clear: a resilient, equitable and sustainable economy must be both local and circular––and the solutions to make this possible are on the rise.

To bring this future to life, more investment in local infrastructure, more collaboration across public and private stakeholders, and a renewed focus on capturing the value of materials used to power our economy will be critical. By bringing together localization and material circulation, we can unlock powerful incentives for our communities: increased value, reduced costs, improved agility and pride, to name just a few.

As we look toward an increasingly evolving future––with climate impacts and economic changes, but also with opportunities to rethink the status quo––the importance of this work will only grow. A local circular economy offers a pathway for communities to thrive and adapt to the challenges ahead. It is the key to a prosperous future.

Disclosures

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Capital Management or any company in which Closed Loop Capital Management or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Closed Loop Capital Management does not utilize its website to provide investment or other advice, and nothing contained herein constitutes a comprehensive or complete statement of the matters discussed or the law relating thereto. Information provided reflects Closed Loop Capital Management’s views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision.

Executive endorsements of Closed Loop Capital Management are for illustrative purposes, designed to attract business development contacts, and should not be construed as a client or investor testimonial of Closed Loop Capital Management’s investment advisory services. All such endorsements are from current or former portfolio company leadership about Closed Loop Capital Management’s ability to provide services to their companies. Closed Loop Capital Management has not, directly or indirectly, paid any compensation to such individuals for their endorsements.

The case studies presented in this material have been included as representative transactions to illustrate the platforms, technology and manufacturing capabilities of Closed Loop Partner’s partner companies and are not based on the performance of any investment. The case studies presented in this material are not representative of all Closed Loop Partners’ investments and are not reflective of overall results of any of Closed Loop Partners’ businesses. Not all Closed Loop Partners investments had or will have similar characteristics or experiences as those included herein.

Certain information on this Website may contain forward-looking statements, which are subject to risks and uncertainties and speak only as of the date on which they are made. The words “believe”, “expect”, “anticipate”, “optimistic”, “intend”, “aim”, “will” or similar expressions are intended to identify forward-looking statements. Closed Loop Capital Management undertakes no obligation to update publicly or revise any forward-looking statements, whether as a result of new information, future developments or otherwise. Past performance is not indicative of future results; no representation is being made that any investment or transaction will or is likely to achieve profits or losses similar to those achieved in the past, or that significant losses will be avoided.

Related posts

Blog Post

How AI Can Reduce Food Waste at Restaurants

Closed Loop Ventures Group led the seed investment...

Press Release

New Data Reveals High Quantities of Food-Grade Polypropylene...

Closed Loop Partners’ Center for the Circular Economy...

Press Release

Closed Loop Partners and U.S. Plastics Pact Identify...

Packaging types primed for reuse lay the groundwork...

Blog Post

Why We Invested in Mycocycle: Nature-Inspired Circular...

Closed Loop Partners’ Ventures Group saw a key opportunity...

Press Release

Groundbreaking Results From Citywide Petaluma Reuse...

The Petaluma Reusable Cup Project from the NextGen...

Press Release

Closed Loop Partners’ Portfolio Company, Sage Sustainable...

The bolt-on acquisition scales Sage’s end-to-end...

Press Release

Closed Loop Partners Unveils Groundbreaking Findings...

Closed Loop Partners’ Center for the Circular Economy...

Press Release

Capricorn Investment Group Backs Closed Loop Partners...

The partnership signals tailwinds behind the circular...

Blog Post

8 Tips to Navigate Life Cycle Assessments for Circular...

Closed Loop Partners’ Center for the Circular Economy...

Press Release

Closed Loop Partners Leads $4M Seed Round for LAIIER,...

Investment in the innovative liquid leak detection...

Blog Post

Why More Composters Are Recovering Food Scraps and...

Black Earth Compost and Glacial Ridge Composting Facility...

Blog Post

Scaling Circular Solutions: Why Access to the Right...

A case study on the growth of Minus Works, a company...