MATERIALS RECOVERY AND RECYCLING

While innovative materials and design are central to the NextGen Consortium’s ambition to address single-use foodservice packaging waste globally, the end-of-life recovery of packaging––including to-go fiber cups––through recycling and composting infrastructure is equally important. Alignment with collection, sortation & processing systems and end markets is critical to create pathways for recovery and eliminate waste to landfill.

Given the inconsistency of regional recycling regulations and the diversity of recovery infrastructure, closing the loop on foodservice packaging requires an understanding of the current infrastructure landscape, best practices and stakeholders at every step of the value chain.

For NextGen Cup, as part of our assessment of the best path forward for a more widely recyclable or compostable fiber cup, we mapped the current journey of the cup and interviewed key cup manufacturers, waste collectors, materials recovery facilities (MRFs), municipalities, paper mills and other value chain stakeholders to gather expert insights on the state of cup recycling and composting, challenges and opportunities.

Cup Recovery Infrastructure Highlights

Infrastructure Tests

Show moreSelect NextGen Cup teams take part in a rigorous series of infrastructure tests to evaluate the recyclability and sustainability performance of their cup solutions. Tests include lab-scale repulping and recycling trials, MRF sortation studies, microplastic detection analysis, chemical hazard assessments, converter trials and commercial-scale mill trials, among others. Testing commenced in early 2020 and will continue into 2021.

Multi-Stakeholder Workshops

Show moreIn June 2019, the NextGen Consortium convened brand partners and more than 25 experts from across the recovery infrastructure system to identify strategies and next steps for this critical work stream, including standardizing cup formats, avoiding regrettable substitutions through comprehensive environmental and human health testing, and strengthening end markets for recycled content. The Consortium plans follow up engagements in 2021 and beyond.

Mill and MRF Engagement

Show moreThe NextGen Consortium continues to engage and test cups at paper mills and MRFs across the country to evaluate cup recovery. Validating cups at scale through these channels is critical to strengthening market pulls. Among our highlights in September 2020, the Consortium supported Georgia-Pacific in their announcement to accept cups at two of their recycled paper mills. See below for more information. We look forward to continuing to engage and support a wide array of mill and MRF partners moving forward.

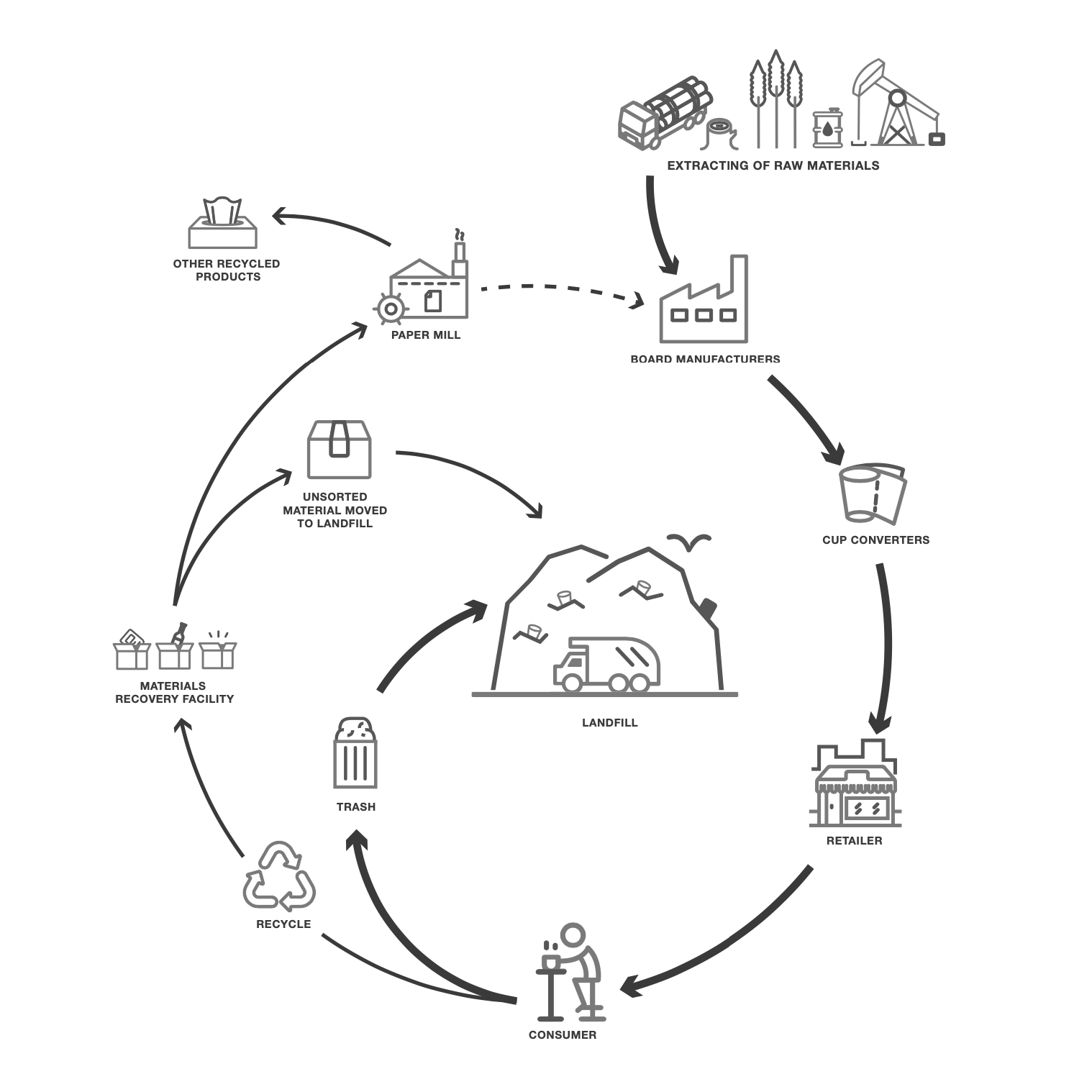

The Current Journey of the Cup

While fiber cups are technically recyclable, in many markets, you can’t recycle them. Even in markets where you can, many cups don’t find their way through the proper channels and even when they do, you still have to manage the leftover PE cup liner, present in most current cup formats. In practice, the vast majority of fiber cups end up in landfills today. Consumers are confused as to the proper disposal method (it varies from place-to-place), MRFs are deterred by the lack of volume of cups entering their facilities and some paper mills are concerned about potential contamination of their recycled paper stream. The inconsistencies and spatial gaps across the recovery infrastructure result in too many cups finding their way to landfill––wasted.

We want to change that. By connecting upstream product and service innovation to downstream recovery infrastructure, and focusing on understanding and integrating new cup solutions within existing recovery systems, we can keep the valuable fiber in the cup in circulation.

The six participating cup companies in our NextGen Circular Business Accelerator all ran their new cup solutions through MRFs to see first-hand what happens to their cups at end-of-use. They also explored the value of their cup materials post-processing to better understand the market incentives for recycling or composting, which are ultimately driven by end markets.

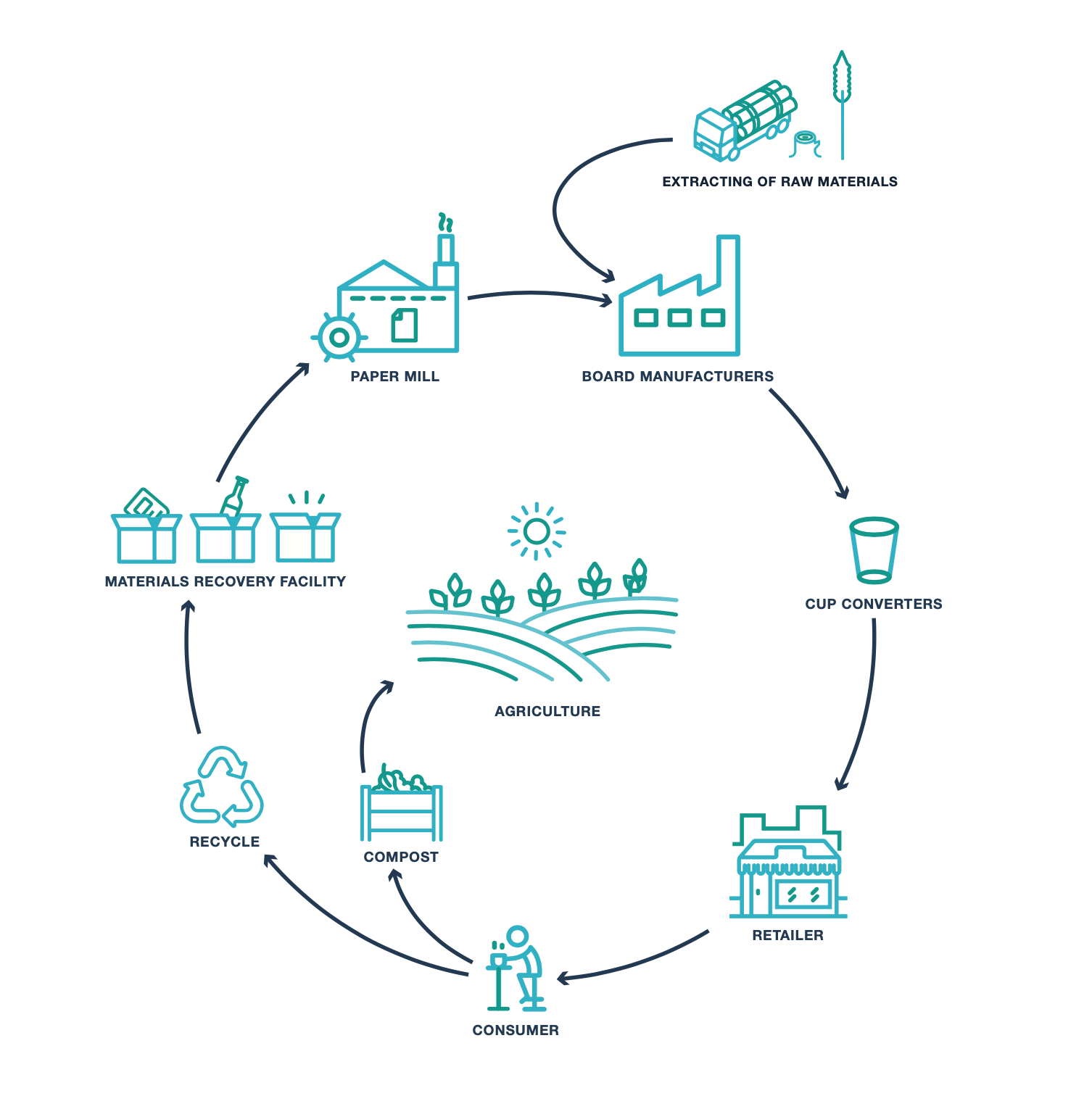

The Future Journey of the Cup

Through the NextGen Consortium’s integrated, holistic approach to aligning product design with infrastructure, together, we can achieve a waste-free future journey of the cup in which materials are continuously cycled and the emphasis on the extraction of raw materials is reduced. In this setting, the materials in cups continue their lifecycle and we move closer to achieving circularity.