Closed Loop Partners Unveils Groundbreaking Findings on Small-Format Packaging Recovery, Advances Collaboration with Major Brands for New Industry Consortium to Reduce Plastic Waste

February 19, 2025

Closed Loop Partners’ Center for the Circular Economy calls on brands to join critical work to increase recovery of valuable small-format plastic packaging typically lost to landfills

NEW YORK, Feb. 19, 2025 — Today, Closed Loop Partners’ Center for the Circular Economy unveils major pioneering findings in a new report on small-format plastic packaging recovery. The report builds on over two years of market research and comprehensive recycling tests in partnership with Maybelline New York and its parent company, L’Oréal Groupe, bolstered by the support of additional partners Kraft Heinz, P&G and Target.

The findings reveal a viable pathway to recover tens of thousands of tons of valuable small materials––including plastics like polypropylene––from materials recovery facilities (MRFs) and glass recycling plants across the U.S. With the right equipment upgrades and reconfigurations, significant volumes of these materials can be successfully recycled instead of being lost to waste. For example, upgrading the glass screen—a type of material sorting equipment—at a MRF resulted in a 67% relative reduction in mid-to-large-sized “small” plastics contaminating the glass stream. Materials that would have otherwise been considered contaminants and discarded at the glass recycling plant are now effectively sorted and directed into appropriate bales for sale in the recycled materials market. These promising findings demonstrate the positive economic and environmental impact of recovering small-format packaging, catalyzing the launch of a new industry collaboration managed by Closed Loop Partners’ Center for the Circular Economy: the Consortium to Recover Small-Format Packaging.

Each year, consumers buy billions of products—beauty items, medications and food—packaged in small-format plastic that is difficult to recycle due to its size and other factors. Currently, most of this is discarded into trash bins, ending up in landfills or incinerators. The small fraction that does end up at recycling facilities often slips through sorting equipment due to its size, contaminating the glass stream and ultimately being sent to landfills. As brands work to meet waste reduction goals and achieve compliance with Extended Producer Responsibility legislation, the opportunity to capture previously unrecovered small-format plastic packaging can have a significant positive impact.

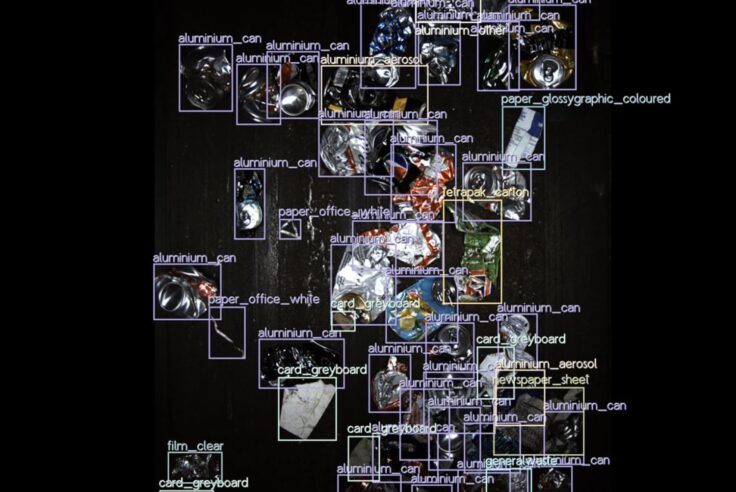

The Center for the Circular Economy conducted its research in collaboration with Circular Services, a Closed Loop Partners company. Circular Services operates over 20 MRFs across the U.S. and manages municipal contracts in major and rapidly growing cities, including New York City, Austin, San Antonio and Phoenix. With support from partners Maybelline New York and its parent company, L’Oréal Groupe, Kraft Heinz, P&G and Target, the Center conducted an extensive, in-field process to identify solutions for small-format packaging recovery. This included evaluating glass stream contamination at more than half a dozen MRFs across the U.S. The Center collected samples from two MRFs’ glass streams and one glass recycling plant’s residue streams; trialed equipment configurations to sort plastics from these streams; sent samples to reclaimers to test their processability and market value; and iterated this process multiple times.

The report highlights five key insights critical to the recovery of small-format packaging:

- Many small format plastic materials hold significant market value

- Logistical solutions already exist to handle them

- Current technologies can be adapted to effectively recover portions of them at MRFs and glass recycling plants

- Market demand for these materials is strong—especially from mechanical recyclers

- Targeted investment at recycling facilities is essential to build a compelling, scalable business case to recover smaller materials

These findings can apply to recycling facilities across the country, meaning tens of thousands of tons of plastics could be recovered annually, avoiding landfill and generating market value.

The Center for the Circular Economy’s new findings lay the necessary groundwork and provide the rigorous diligence needed for the creation of a new industry consortium, the Consortium for Small-Format Packaging Recovery. The Consortium is focused on advancing the recovery of small-format packaging by testing the Center’s latest findings in real-world scenarios across the U.S. The Center is inviting research-phase partners to join, while also expanding participation to brands across various sectors. This is a cross-industry challenge, as small-format packaging is used in beauty, pharmacy, foodservice, beverage, retail and beyond.

One next step to build upon the findings is investment in equipment and infrastructure upgrades for rigid small plastics recovery in the field. The Center for the Circular Economy anticipates a quantifiable tonnage of materials diverted from landfill, carbon emissions avoided and post-consumer recycled content generated. The Consortium will lead the establishment and engagement of a robust value chain for recovery of small materials, from recyclers, reclaimers, policymakers and more.

If your company is part of the small-format packaging value chain—whether as a manufacturer, brand owner or other stakeholder—and is interested in joining the Consortium to Recover Small-Format Packaging to advance collaboration, recycling infrastructure investments and policy for nationwide recovery, contact the Center for the Circular Economy here.

“We’re eager to put our findings to the test and, through the Consortium to Recover Small-Format Packaging, deploy equipment and infrastructure upgrades to drive real-world proof-of-concepts in the field. It’s critical that we advance solutions to recover valuable small-format materials, like polypropylene, that otherwise typically end up in landfill. This is inherently a cross-industry challenge, as small-format packaging is used in beauty, pharmacy, foodservice, beverage, retail and beyond. We’re inviting our research-phase partners and brands across various sectors to join the Consortium and help address an urgent waste challenge.” Kate Daly, Managing Partner, Closed Loop Partners’ Center for the Circular Economy

“L’Oréal is excited to partner with Closed Loop Partners to develop innovative solutions for recovering packaging materials, reducing waste and creating opportunities in a fragmented national recycling infrastructure. Closed Loop Partners’ Center for the Circular Economy provides practical and scalable approaches for recovering small-format plastics that end up in landfills. We believe scaling these innovations will improve the recyclability of plastic and create a viable end-market for our materials.” Marissa Pagnani McGowan – Chief Sustainability Officer, North America for L’Oréal Groupe

“As the number one makeup brand in the world, we have a responsibility to create the most sustainable makeup life cycle possible. Most makeup packaging is too small to be recycled, it literally falls through the cracks at recycling facilities. That’s why it was so important to partner with Closed Loop Partners’ Center for Circular Economy to pioneer solutions for small-format recycling and to help us and the beauty industry accelerate our sustainable transformation. We look forward to making progress together.” Trisha Ayyagari, Global Brand President, Maybelline New York

“At Kraft Heinz, we know collaboration is the key to unlocking solutions for the future of packaging. We are proud to partner with Closed Loop Partners on this groundbreaking research to advance packaging solutions, improve end-of-life recovery and enhance critical infrastructure. By working together, we can drive meaningful change and create a more sustainable future for food.” Linda Roman, Director of Packaging R&D and North America R&D Fellow, Kraft Heinz

About Closed Loop Partners’ Center for the Circular Economy

The Center for the Circular Economy at Closed Loop Partners is a trusted innovation and research hub, partnering with the world’s most influential organizations to solve their toughest material challenges.

As part of Closed Loop Partners’ platform, the Center identifies solutions, tests them in real-world settings and scales what works—transforming bold ideas into actionable, scalable strategies. Over the past seven years, the Center has led groundbreaking projects that reshape industries and redefine sustainability.

Learn more about the Center at closedlooppartners.com/thecenter.

Related posts

Blog Post

How AI Can Reduce Food Waste at Restaurants

Closed Loop Ventures Group led the seed investment...

Press Release

New Data Reveals High Quantities of Food-Grade Polypropylene...

Closed Loop Partners’ Center for the Circular Economy...

Blog Post

Keeping Compost Clean: Tools to Help Reduce Contamination...

The Composting Consortium interviews EcoProducts to...

Press Release

Closed Loop Partners and U.S. Plastics Pact Identify...

Packaging types primed for reuse lay the groundwork...

Blog Post

Why We Invested in Mycocycle: Nature-Inspired Circular...

Closed Loop Partners’ Ventures Group saw a key opportunity...

Press Release

Groundbreaking Results From Citywide Petaluma Reuse...

The Petaluma Reusable Cup Project from the NextGen...

Press Release

Closed Loop Partners’ Portfolio Company, Sage Sustainable...

The bolt-on acquisition scales Sage’s end-to-end...

Press Release

Capricorn Investment Group Backs Closed Loop Partners...

The partnership signals tailwinds behind the circular...

Blog Post

8 Tips to Navigate Life Cycle Assessments for Circular...

Closed Loop Partners’ Center for the Circular Economy...

Press Release

Closed Loop Partners Leads $4M Seed Round for LAIIER,...

Investment in the innovative liquid leak detection...

Blog Post

The Key to a Strong Local Economy? It Must Be Circular.

4 ways the circular economy unlocks local value.

Blog Post

Why More Composters Are Recovering Food Scraps and...

Black Earth Compost and Glacial Ridge Composting Facility...