Circular Supply Chains Need Intelligent and Distributed Manufacturer Networks

November 22, 2021

Gone are the fleeting days of component parts showing up just in time for production from an unknown combination of suppliers. After pioneering the just-in-time supply chain, Toyota responded to the Fukushima disaster by stockpiling critical components — such as semiconductor chips — with enough supply for months at a time. That was a decade ago.

Now, Toyota may be doing better than its competitors while a global chip shortage costs the automotive industry upwards of $110 billion in car sales. However, more industries are recognizing the limitations of a just-in-time strategy applied broadly to every component part and raw material across globalized supply chains.

As unforeseen disruptions increase — whether the COVID-19 pandemic or climate-related natural disasters — and as more products demand critical, limited resources, intense fluctuations in demand, labor shortages, inadequate equipment and physically damaged facilities contribute to an instability of manufacturing capacity. Underdeveloped manufacturing capacity leaves industries exposed to risk, price volatility, market dislocations and lost value.

Unfortunately, first-mile stakeholders in the supply chain are often most at risk of losing value in the face of disruptions. For example, demand for lumber sharply increased when homeowners sought to remodel and build new houses during the COVID-19 pandemic. Meanwhile, U.S. sawmills (largely Canadian-owned) had to shut down over 40 percent of their capacity during this same time period. Yet forestry growers — producing timber that becomes lumber — suffered in a buyer’s market and saw prices for timber remain low: When adjusted for inflation, timber prices are at their lowest over the past 50 years.

While the market has since recalibrated and the lumber bubble may be just one instance in which supply was ill-prepared to manage demand, the whole of today’s U.S. manufacturing is just 11 percent of GDP — near its lowest in over 70 years. Underdeveloped manufacturing capabilities from generations of regional specialization pose significant risk to meeting demand and climate goals. U.S. Secretary of Energy, Jennifer Granholm recently wrote: “We have weak domestic supply chains for technologies critical to our economic and national security… China is the only country with control over every tier of the supply chain for critical materials like the lithium we need for vehicle batteries, including 80 percent of raw material refining capacity… Other countries, especially China, produced 85 percent of transformers for our electric grid — while America still produces almost none.”

The automotive, energy and tech industries must contend with critical rare earth metal supply chains needed for everything from batteries to solar panels. These products are reliant on limited resources, often harmfully extracted from biodiverse regions fraught with social inequities. The ability to (re)manufacture and recycle these raw materials efficiently and locally is critical to business continuity in an increasingly resource-constrained world.

The time is now: Advances in automation and machine learning, rising pay globally and increasing risk from supply chain disruptions suggest that onshoring manufacturing is increasingly attractive to many product producers. Against this backdrop, what do resilient and circular supply chains look like? Supply chain managers are finding the right instances to:

- Create visibility into manufacturing supply chains to better prepare for and manage risk

- Produce with distributed, more regionally resilient supply networks

- Source feedstocks locally and from more available recycled content

Smart entrepreneurs are seizing the moment to build more resilient, circular supply chains. Partsimony, a company dedicated to building cognitive supply chains and increasing efficiencies, closed a $2 million seed round led by Closed Loop Partners’ Ventures Group with participation from Contour Ventures, Urban Us and other top institutional and angel investors. Partsimony applies machine learning to build a predictive and dynamic manufacturing market network, helping solve for the manufacturer discovery and price quoting process for complex hardware companies — which can be an opaque, manual and excel-based process today for both the hardware company and the manufacturer. Partsimony provides hardware companies with a better, real-time understanding of their manufacturers’ capabilities and pricing, helping them iterate and commercialize products faster and with increasingly distributed supply chains. Partsimony also supports the manufacturer by serving as a qualified lead generation platform to acquire customers whose products match technical capacity (production methods and volumes) and help manufacturers maximize margin.

Partsimony’s platform demonstrates how increased transparency and intelligence across supply chains can ultimately benefit business, people and the planet through three core activities:

Digitizing supplier relationships creates transparency

When supply chain disruptions happen, hardware companies need better control over their production and transparency into their suppliers to adapt quickly. Case in point: Toyota knew to safeguard its chip supply because of the company’s “no black box” approach, only adopting technologies it truly understands, down to the gases and the metals of each component. This supply chain visibility — down to the material level — is a critical driver of resiliency, and we invested in Partsimony because its platform helps enable this kind of visibility.

Distributed manufacturing supply chains shorten lead times

Adopting a distributed manufacturer network of on-shore manufacturing within existing off-shore manufacturing supply chain networks is increasingly becoming a competitive advantage. This is not about an America-first dogma; on-shoring of manufacturing helps regionalize the production for any supply chain. Doing so shortens lead times and helps diversify the supplier base. Distributed manufacturer networks are primarily about developing resilient and sustainable business practices, with the added benefit of reducing emissions associated with the international transportation of raw materials and finished component parts. Working with customers such as Stanley Black & Decker, Partsimony has demonstrated 96 percent cost reductions and 83 percent lead time reductions.

Data-driven recommendations can leverage engineering insights and incentivize use of recycled content

Design and material selection have an outsized impact on the circular impact of products. A poorly designed product may choose hard-to-recycle and fossil fuel-based materials in formats where the materials are intermingled and difficult to separate for recovery — a product William McDonough would call a “monstrous hybrid.” Now, Partsimony’s AI supports hardware companies in testing novel, more sustainable materials and alternative manufacturing methods in products from the very first point of design. Engineers upload their digital designs or CAD files to the platform, and Partsimony is building its AI to read the structural requirements of the component part and potentially recommend materials from recycled content, as well as alternative manufacturing solutions.

Digital visibility, distributed manufacturer networks and data-driven infrastructures are the circular antidotes to today’s analog and fragile supply chains. The COVID-19 pandemic is not the first black-swan event within this century, and it most certainly will not be the last. Climate-related disasters will continue to upset business-as-usual, just-in-time production and manufacturing. If we want to design more circular products with more socially equitable access, we must also capitalize on the supply chain disruptions in front of us to redesign our supply chain to be more resilient and more circular.

Originally published in GreenBiz

Related posts

Blog Post

Why We Invested in Mycocycle: Nature-Inspired Circular...

Closed Loop Partners’ Ventures Group saw a key opportunity...

Press Release

Closed Loop Partners Leads $4M Seed Round for LAIIER,...

Investment in the innovative liquid leak detection...

Blog Post

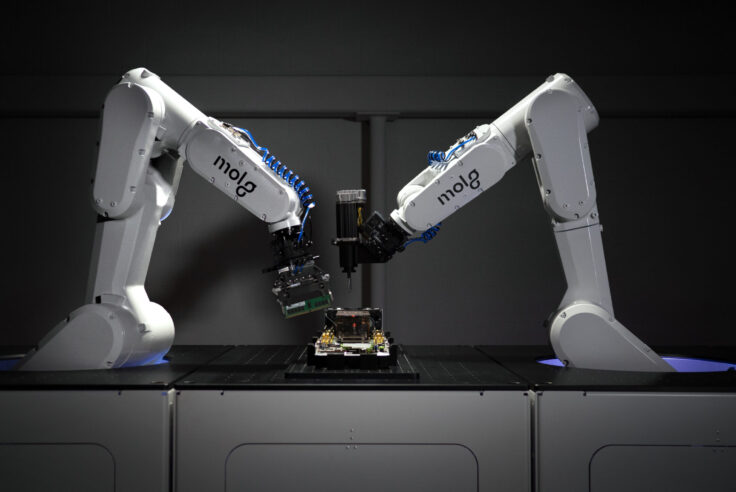

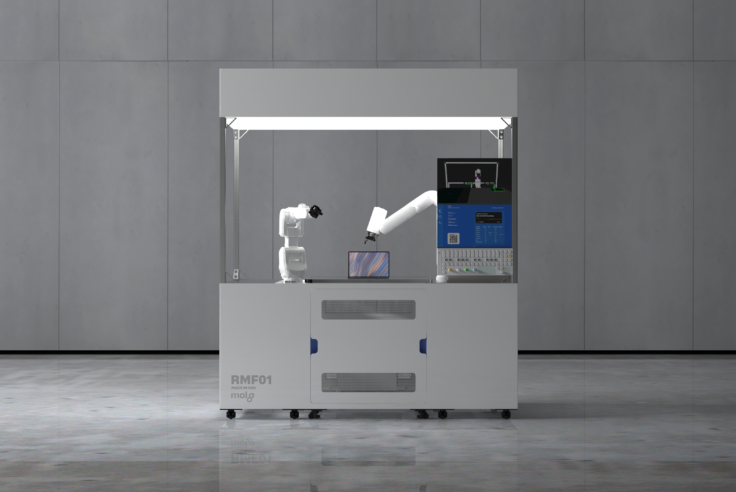

Making Circularity Stick: Electronics

A conversation with Rob Lawson-Shanks, CEO of Molg...

Press Release

Closed Loop Partners Doubles Down on Investment in...

Closed Loop Ventures Group joins Earthodic's $4 million...

Blog Post

Why We Invested in Neutreeno: Engineering Circular...

Neutreeno offers a game-changing solution that seamlessly...

Press Release

Molg Raises $5.5 Million in Seed Funding to Tackle...

Closed Loop Partners' Ventures Group leads seed funding...

Blog Post

How the Apparel Industry Is Challenging Us to Think...

The high cost of textile waste has sparked the need...

Blog Post

Why We Invested in Aerflo: Making Reuse an Everyday...

Closed Loop Ventures Group is thrilled to announce...

Blog Post

Why We Invested in Capra Biosciences: How Microbes...

Today, we are witness to a rapidly changing manufacturing...

Blog Post

Why We Invested in VALIS Insights: Bringing Circularity...

Closed Loop Partners invested in VALIS Insights because...

Blog Post

Why We Invested in Found Energy: The Importance of...

Closed Loop Ventures Group invests in Found Energy,...

Blog Post

Why We Invested in Molg: Supporting the Circular Economy...

Closed Loop Ventures Group shares how Molg Inc. is...