NextGen Consortium Begins Piloting Sustainable Cup Solutions in San Francisco Bay Area

February 18, 2020

Local cafes join the Consortium’s efforts to advance reusable, recyclable and/or compostable cup solutions in select pilots

SAN FRANCISCO, Feb. 18, 2020 /PRNewswire/ — Today, the NextGen Consortium — a multi-year consortium that addresses single-use food packaging waste globally by advancing the design, commercialization and recovery of food packaging alternatives — announced the launch of reusable cup pilots in local cafes in the City of San Francisco and City of Palo Alto, CA.

Two of the 12 NextGen Cup Challenge winners – CupClub and Muuse – will pilot their respective “smart” reusable cup systems in open environments across clusters of local cafes on a rolling basis over the coming weeks. Live piloting offers these cup companies the opportunity to further test, learn and innovate according to the unique material, technical and operational changes necessary to facilitate a seamless and convenient transition to reusable cups for customers and companies. The size and complexity of the pilots, along with the customer feedback and data captured during them, will provide valuable insights into each cup’s technical feasibility, business viability, user desirability and circular resiliency. Alongside participating local cafes, the City of Palo Alto will be hosting cup drop off points in a number of civic buildings downtown and the City of San Francisco has helped to facilitate connections with local businesses.

Scaling the next generation cup won’t happen overnight; the cup system is complex and calls for multiple layers of testing. From the ability for baristas and customers to handle cups with ease, to alignment with diverse waste recovery systems after-use, testing is key. Reusable cup systems will need to be cost-competitive, integrate smoothly across diverse operations and technology platforms, minimize operational disruption, and have a positive impact on the environment and meet the convenience and performance standards customers know and trust in order to scale.

These pilots build on the NextGen Consortium’s work to advance the development of new, alternative cup solutions through the necessary iterative loops of innovation and testing before scaling. Additionally, in March, two NextGen Cup Challenge winners — Footprint LLC and PTT MCC Biochem Company Limited — will also begin pilots in cafes in Oakland, testing their single-use cup solutions that pioneer alternative materials for cups and cup liners that are recyclable and/or compostable. These ensure that the valuable materials in cups are kept in circulation and out of landfills and the natural environment.

The NextGen Consortium is managed by Closed Loop Partners’ Center for the Circular Economy. Starbucks and McDonald’s are founding partners, with The Coca-Cola Company, Yum! Brands, Nestlé and Wendy’s as supporting partners, The World Wildlife Fund as the advisory partner and global design firm IDEO as the innovation partner. IDEO is designing and running the pilots in the San Francisco Bay Area on behalf of the NextGen Consortium.

“We know finding a more sustainable cup solution will continue to require partnership and innovative thinking,” says Michael Kobori, Chief Sustainability Officer at Starbucks. “The ongoing work from the NextGen Cup Consortium provides valuable insights and learnings for all the members, us included, as we continue to explore a variety of ways to better manage our waste and reduce our environmental footprint.”

“We’re excited to see many of the winning ideas become potential solutions that can be tested in a customer-facing environment,” says Marion Gross, Senior Vice President and Chief Supply Chain Officer, McDonald’s North America. “Finding a cup that can be scaled will require continued innovation, testing and honing of solutions, so these pilots are an important step forward on that journey.”

Together, the NextGen Consortium’s unprecedented collective of brands are helping to shape the ultimate form these cup innovations will take in the world. “As we strive to build a more circular economy in which we design out waste, unique partnerships are essential,” says Kate Daly, Managing Director at Closed Loop Partners. “Our work to engage diverse stakeholders, from brands to universities to NGOs, ensures that we create the necessary robust testing framework to help these cup teams succeed.”

These pilots represent one important initiative within the broader work of the NextGen Consortium to create long-lasting, positive change across the cup system. The NextGen Consortium takes a systems view, pairing upstream product innovation with downstream recovery infrastructure. The Consortium brings together leading food and beverage companies to work together pre-competitively to identify and scale solutions that work for the whole industry.

Participating Local Cafes

Reusable Cup Pilots: Palo Alto, CA

CupClub:

- Coupa Cafe:

- Ramona

- 538 Ramona St, Palo Alto, CA

- Lytton

- 111 Lytton Ave, Palo Alto, CA

- GSB

- 655 Knight Way, Stanford, CA

- Green Library

- 571 Escondido Mall, Stanford, CA 94301

- Ramona

- Verve Coffee Roasters

- 162 University Ave, Palo Alto, CA 94301

DROP POINTS

- Cafe Venetia (drop point only):

- 419 University Ave, Palo Alto, CA 94301

- City of Palo Alto (drop point only):

- City of Palo Alto City Hall

- 250 Hamilton Ave, Palo Alto, CA 94301

- City of Palo Alto City Hall

- Coupa Cafe Y2E2 (drop point only):

- 473 Via Ortega, Stanford, CA

Reusable Cup Pilots: San Francisco, CA

Muuse:

- Andytown Coffee Roasters

- 181 Fremont St, San Francisco

- Ritual Coffee Roasters

- 432b Octavia St, San Francisco

- Equator Coffees

- 222 2nd St, San Francisco, CA 94105

- La Boulangerie de San Francisco, Hayes

- 500 Hayes St, San Francisco, CA 94102

Single-Use Cup Pilots: Oakland, CA

Footprint LLC:

- Red Bay Coffee

- 3098 East 10th Street Oakland, CA 94601

- 2327 Broadway Oakland, CA 94612

- 1503 Macdonald Ave Richmond, CA 94801

- Equator Coffees

- 175 Bay Pl, Oakland, CA 94610

PTT MCC Biochem Company Limited:

- Snow White Coffee

- 3824 Piedmont Ave, Oakland, CA 94611

About NextGen Consortium

The NextGen Consortium is a multi-year, global consortium that addresses single-use food packaging waste globally by advancing the design, commercialization, and recovery of food packaging alternatives. The NextGen Consortium is managed by Closed Loop Partners’ Center for the Circular Economy. Starbucks and McDonald’s are the founding partners of the Consortium, The Coca-Cola Company, Yum! Brands, Nestlé, and Wendy’s are supporting partners. The World Wildlife Fund (WWF) is the advisory partner and IDEO is the innovation partner. Learn more at www.nextgenconsortium.com.

About Closed Loop Partners

Closed Loop Partners is a New York based investment firm comprised of venture capital, growth equity, private equity, project finance and an innovation center. The firm invests in the circular economy, a new economic model focused on a profitable and sustainable future. Investors include many of the world’s largest consumer goods companies and family offices interested in investments that provide strong financial returns and tangible social impact. In 2018, Closed Loop Partners launched the Center for the Circular Economy, a New York City-based collaboration center for innovators to commercialize products, services and technologies that are leading the transition from a linear take, make, waste economy to a restorative one in which materials are shared, re-used, and continuously cycled. Learn more at www.closedlooppartners.com.

Contact: [email protected]

SOURCE Closed Loop Partners

Bringing the NextGen Cup to Life

November 18, 2019

From 480 innovative ideas, to live prototyping, to preparing for pilot readiness and beyond, these next generation cups are paving the way for a waste-free future.

The NextGen Consortium is a global initiative convened by Closed Loop Partners’ Center for the Circular Economy. Starbucks and McDonald’s are founding partners of the Consortium, together with supporting partners The Coca-Cola Company, Yum! Brands, Nestlé and Wendy’s, as well as WWF as an advisory partner. OpenIDEO is the Consortium’s innovation partner.

The NextGen Consortium is working to change the future of beverage consumption. Together, brands, industry experts, and innovators are aiming to bring a waste-free to-go cup to market. With 250 billion fiber to-go cups produced annually, the majority of which end up in landfills today, this is not a small task that one stakeholder can solve alone. And that is the spirit in which the multi-brand NextGen Consortium was formed, launched by Closed Loop Partners in 2018 to advance the design, commercialization, and recovery of sustainable food packaging alternatives.

NextGen Cup is the Consortium’s first initiative, which began with an open call for solutions from around the world to redesign the fiber cup so that it’s fully recoverable at a global scale. Twelve winning teams were selected from the 480 submissions, and six of those teams recently completed an accelerator focused on getting their solutions ready to go to market. The accelerator led to significant progress for each of the teams, as they move along the journey from concept to tangible solution—Accelerator teams have now tested their solutions in a live environment, developed scalable manufacturing plans with 1-3 year rollouts, and have made improvements to their cup design to meet specific circular design criteria.

As we reflect on the learnings of brands, innovators, experts, and designers coming together to tangibly move the needle on a global issue, there are three conditions that have continuously contributed to measurable progress.

One: Collective brand investment

Why was this a collective effort, rather than one spearheaded by a single brand alone? Creating and scaling the next generation fiber cup for global recovery or reuse brings a host of challenges throughout the value chain.

From material choice, to cup design, to barista and customer experience, to integration with waste recovery streams (and much, much more), each component must be carefully designed, tested, and prototyped prior to piloting to ensure the solution can perform to the necessary quality and standards.

The NextGen Consortium was intentionally designed to be collaborative, both across the NextGen Consortium brands, and with the solutions themselves. The strategy behind this was two-fold:

- It’s faster together: Pre-competitive collaboration allows these brands to come together and share insights, learnings, and resources, making for a richer knowledge ecosystem overall. Similarly, cross-brand partnerships can send a unified signal to the market; for example, incentivizing wider adoption of sustainable materials or encouraging recovery systems to collect cups. By looking at multiple concepts at once, all stakeholders can move forward faster, including the teams themselves. Shared feedback mechanisms lead to enhanced learning for all involved.

- It’s less risky together: As partners and innovators learn, experiment, and work together across a number of concepts and concept types, all participants receive a clearer picture of what works through shared learnings and aggregated needs. With time and cup solutions iterations, the Consortium can work to mitigate any risks around introducing new concepts to market.

Two: Controlled prototyping experiences

In June 2019, the NextGen Circular Business Accelerator teams conducted live in-context prototyping at three different Google campus cafes in the South San Francisco Bay Area.

The goals of which were to:

- Accelerate learning: Prototyping helps teams learn faster and identify areas in need of development by testing solutions in an environment that is as close to a real market as possible.

- Test the whole system or a single hypothesis: Product and service systems can have a lot of interdependent moving parts. Prototyping is a low-risk way of testing how all of those parts work (or don’t work) together. It’s also useful for testing out a new feature or hypothesis that a team might have.

- Learn from users: Seeing first hand how users (coffee drinkers, restaurant workers, etc.) interact with and react to the solution is invaluable. The ability to hear their comments, answer and ask questions in real time is an important part of the process.

- Decrease risk: If a part of a solution does not work, it’s useful for teams to learn this early while the stakes are lower and while they still have the opportunity to incorporate what they learn into the next iteration of the product.

Choosing Google campuses as the prototyping location was a specific design choice. The closed environment of a campus approximates a high traffic retail cafe while offering the benefits of being able to control for key variables.

Cup teams had the opportunity to learn from a highly engaged group of users, and leverage Google’s network of micro-kitchens to explore multiple iterations of their solutions at the same time. Maintaining control across key variables provided teams with the opportunity to develop a prototyping plan that focused on the needs unique to their specific cup solution. For instance:

- Footprint was testing lid use and performance.

- Colombier was looking to compare different coating applications on their cups.

- CupClub wanted users to try out the UI/UX of their mobile application.

Three: A niche and specialized accelerator

Cup design is incredibly technical. From the integrity and safety of the cup itself, to the ability for baristas and users to handle them with ease, to becoming truly waste-free, constant attention to each and every one of these details (plus many more) required the development of a set of specialized metrics and tracking specific to this ecosystem.

For example, during the Google prototyping, teams were specifically evaluating:

- User experience: Teams explored first-hand how beverage drinkers interact with and react to their solutions. Testing was conducted in a variety of ways including design research interviews, surveys, observations and comments, and deep-dive question sessions.

- Barista experience: Many teams had yet to see and understand how their cups do or do not work within the barista context. This was a key initial exploration to determine how well the cup is nesting / de-nesting, holding up to certain types of drinks being made, as well as overall impressions from baristas on each cup.

- Performance: Teams measured general performance of each cup solution, including: how long cups must hold liquid at this location based on user habits, how well the cup regulated temperature either with / without a sleeve, how well the cup stacked, stored, nested and de-nested within the space, overall lid performance, etc.

- Disposal: Teams tracked where the cups ended up in bins across campuses in order to better understand what signifiers (written, visual, verbal, etc.) helped to inform consumers of the proper disposal method.

Top row: CupClub, ReCup, Muuse. Bottom row: Colombier, Footprint, SoluBlue.

Where cups end up after-use is a critical part of the journey and a key focus of the NextGen Consortium’s work. By connecting upstream cup innovation to downstream recovery infrastructure, and focusing on understanding and integrating new cup solutions within existing recovery systems, the NextGen Consortium aims to keep the valuable materials in cups in circulation. During the accelerator, teams visited and ran their new cup solutions through materials recovery facilities (MRFs) to see first-hand what happens to their cups at end-of-use. They examined the value of their cup materials post-processing to better understand the market incentives for recycling or composting, which are ultimately driven by end markets.

The benefits of focusing on this very specific world of sustainable cups continued to ring clear as teams graduated from the accelerator and pitched their solutions live to NextGen Consortium Partners and a group of investors during Climate Week NYC, in September 2019. When it comes to storytelling and understanding the breadth of solutions available within the fiber to-go cup ecosystems, seeing each of the solutions side by side helped investors, partners, and teams understand the value of each of their approaches. The cup solutions included:

Reusable cups and cup systems solutions:

- CupClub: A returnable cup ecosystem, providing a service for drinks. Think bike sharing, but for cups.

- ReCup: A deposit system for reusable cups. Rent a cup and return it to any participating partner shop. No cleaning of the cup or carrying around required.

- Muuse: A deposit-based platform for smart, reusable beverage packaging, connecting their cups–and third party products–to Internet of Things technologies. (Formerly Revolv)

Single-use fiber cups and liners solutions:

- Colombier: A recyclable and compostable barrier for paperboard cups.

- Footprint: Cups, lids and straws that are fully formed fiber-based solutions, with an aqueous-based coating that is recyclable and compostable.

Innovative new materials:

• Solublue: Plant-based, food grade and non-toxic products that biodegrade after use.

What’s next for the NextGen Cup?

As each of the six teams stepped off the stage during the final accelerator pitch event, the NextGen Consortium entered the next phase of this work: pilot readiness testing.

After the initial prototyping at Google campuses, select teams will now work to increase the size and complexity of their testing locations, looking at universities and offices, among other locations. Additionally, these teams will now begin to prototype alongside select teams from the NextGen Consortium’s “Advanced Solutions Program,” later-stage teams from the NextGen Cup Challenge that did not require the initial accelerator programming. As these teams work to reach market readiness, their greatest need is additional data points that will prove their concept’s ability to operate at scale.

The pilot readiness tests aim to provide much of that data and help setup teams for next steps around scalability. In parallel, the NextGen Consortium will continue its work convening experts and identifying opportunities to align new cup designs and materials with the infrastructure like MRFs, paper mills, and other recyclers that would process them at end-of-use.

From 480 innovative ideas to live prototyping to preparing for pilot readiness and beyond, these next generation cups are paving the way for a waste-free future. These are not solutions that will be ready overnight and require multiple layers of testing and iteration. That’s why NextGen Cup has a multi-stage, multi-year approach to identifying, testing, and scaling sustainable cup solutions to integrate into the global supply chain.

NextGen Cup is designed to both acknowledge the complex journey of the cup, from design through to cup recovery after-use, and accelerate it by de-risking the process in its collective efforts and creating methods for effective prototyping and pilot readiness.

The Latest Insights and Analysis from Chris Cui, Director of Asia Programs

Chris shares her latest thoughts and takeaways from a recent trip to China where she attended the 14th China International Plastics Recycling Conference & Exhibition and visited a local MRF.

China’s Material Recovery Facilities Are Fast Adapting To A Post National Sword World

We gained valuable market insights from policy makers and market practitioners at the 14th China International Plastics Recycling Conference & Exhibition in September in Shanghai. The discussion focused on how stakeholders across the recycling system should work together to develop a domestic closed-loop ecosystem. This means doubling down on collection, transportation, and reprocessing efforts to enable brands to reach their circularity goals. It became clear that the Chinese government is determined and committed to supporting the development of the circular economy in the coming years by carrying out the following policies:

- Implementing a tax to support the recycling industry

- Creating green standards for recycled plastic and for the production of recycled plastic

We saw firsthand the rationale behind these policies that are being considered. Mr. Wang, the Secretary of CRRA, was also quick to note the number of new faces in the room, including brand owners and capital providers, like Closed Loop Partners and the Alliance to End Plastic Waste. This helped to send a strong signal to the recycling industry around the business case for the circular economy.

Chris promoting the circular economy to brand owners & the recycling industry in China, Shanghai.

Witnessing The Transformation Of A Traditional MRF Into A Tech Enhanced One

It’s been three months since mandatory trash sorting was enforced in Shanghai and other big cities across China. We visited a local MRF to see how the new laws have impacted business. Tianqiang, led by CEO Mrs. Hu, has transformed its business model from a MRF to an all encompassing solutions provider, adding collection, reprocessing and production capacity.

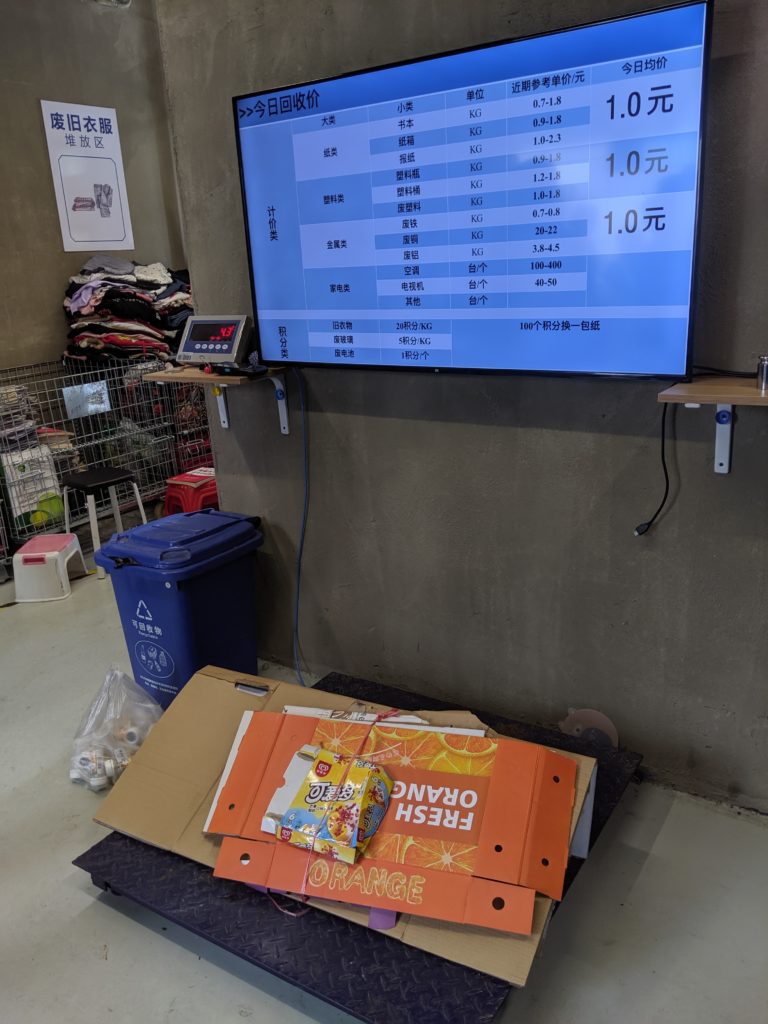

- Tianqiang has implemented technology enabled collection services. They have set up café style smart collection centers with digital scales that are linked to real time commodity prices. Residents get paid immediately by cash or credit according to the commodity price on a given day. Also, operators of the MRF are able to see the exact amount of recyclables collected from each transaction and accumulated at each center on a dashboard. This data helps inform the local government’s waste reduction targets for different communities.

Weighing paper recyclables at Tianqiang.

- Tianqiang is embracing vertical integration. Although their recycled plastic is sold mainly to car and furniture manufacturers, they are also producing their own products such as clothes hangers to sell to retailers. Their recycled paper is being sold directly to the no. 1 and no. 2 paper products manufacturers in China.

- Tianqiang’s collection centers are rent free, strengthening an earlier point that the Chinese government is supporting the development of local recycling infrastructure, for example by providing free land to encourage private sector growth.

Locals separating and sorting recyclables at Tianqiang.

A Linear Take-Make-Waste Economy Has Prevailed For The Last 50 Years, But The Circular Economy Is Where Value Will Be Created In The 21st Century

We have reached an expiration date on the current linear economic system that throws valuable resources away.

When did we stray so far from the common sense value of not wasting? Until the 1950s, people designed products to be proud of their quality and durability. Repair services were a given; a tailor would risk reputational ruin if their clothes had to be tossed after one wear. During the first and second World Wars, recycling was viewed as a patriotic duty. Recycling and reuse were championed. Rubber, metals, textiles, and cooking fats, among other things, were essential to the war effort. And so Americans rallied.

Today, rather than continue to evolve towards conservation and resource efficiency, we seem to devolve into a world of waste and pollution. Approximately 50% of all food produced in the U.S. is thrown out, and food waste is the biggest occupant in American landfills, costing taxpayers billions in landfill disposal fees. Americans throw out 80 pounds of clothing each year. And about 90% of plastic waste ultimately ends up in a landfill or incinerated. The statistics go on, but the loss of these resources has a double sting: there’s a hefty price tag attached to all this waste and dire implications for our health.

A throw “away” culture, while financially beneficial to companies that extract natural resources like oil and mining companies and landfill operators, causes a massive financial hardship to municipal budgets. Landfill tipping fees per metric ton can exceed $100 in the United States and landfills are the third largest source of methane emissions in the world. Ultimately, these costs are paid by taxpayers and municipalities.

The materials we pay to landfill are often valued commodities. Plastics, paper, textiles, and metals can be reused, repurposed, and can re-enter manufacturing supply chains. The recycling industry is a powerful engine in the economy; in 2018, the industry created over $110 billion in economic activity, 534,000 jobs, and $13.2 billion in tax revenues for governments across the country. Only 30% of what can be recycled in the United States is recycled due to a lack of recycling and circular economy infrastructure in many parts of the United States. That means that there is an opportunity to 3x the already substantive jobs and economic value created by the recycling industry.

Given all of this, why are we still following a linear economic model that culminates in wasted resources? Over time, a number of different forces have contributed to the current state of play. In the 1950s, there was a marked shift away from the “waste not, want not” approach to life, replaced instead by a feverish post-war consumption boom where status came to be defined by the quantity of products consumed as opposed to the quality of products produced.

By 1960, the prevailing indicator of the health and success of a country was its gross domestic product – the total value of goods and services provided – rather than attributes like quality of education, air, water, and green spaces, among other things. In the 1970s, economist Milton Friedman declared that the only responsibility of business is to increase profits, establishing the precedent of shareholder primacy which ignores and discounts other stakeholders like local communities and the environment.

While consumers, taxpayers, and the environment lose out in this current take-make-waste economy, extractive industries, like oil & gas and landfill owners win. But we can reimagine this system and an alternative does exist: it is the circular economy, and it’s gaining traction.

The circular economy represents the most significant restructuring of global commerce since the industrial revolution. It is an overhaul of how products are designed, manufactured, sold, consumed, refurbished and recycled, eliminating the concept of waste and keeping materials in circulation at their best and highest use. This new economic model reduces the need for the extraction of finite raw materials and the costly disposal of waste at landfills.

Today is the perfect opportunity to reflect on this shift, since recycling is a key enabler of the circular economy. On America Recycles Day, Closed Loop Partners is celebrating the potential of the circular economy to reimagine capitalism in order to reduce costs, increase efficiency, and protect the environment we share.

The circular economy is estimated to be worth $4.5 trillion globally by 2030. Large consumer goods companies are increasingly recognizing that the development of circular supply chains will reduce manufacturing costs and provide consumers with more sustainable products. Similarly, governments are seeing how local recycling and circular economy infrastructure reduce municipal disposal budgets, generate revenue and drive local job creation. The transition to circularity will rely on collaboration across the entire value chain, including product designers, recyclers, manufacturers and brands. In doing so, we will align the interests of citizens, municipalities, industry and the environment we all share.

America’s Leading Beverage Companies Unite To Reduce New Plastic Use & Increase Collection Of Their Valuable Bottles Through ‘Every Bottle Back’ Initiative

The Coca-Cola Company, PepsiCo and Keurig Dr Pepper Will Support Circular Plastics Economy Through Investment and Action, in Conjunction with World Wildlife Fund, The Recycling Partnership & Closed Loop Partners

WASHINGTON – America’s leading beverage companies – The Coca-Cola Company, PepsiCo and Keurig Dr Pepper – today announced the launch of the Every Bottle Back initiative, a breakthrough effort to reduce the industry’s use of new plastic by making significant investments to improve the collection of the industry’s valuable plastic bottles so they can be made into new bottles. These competitors are coming together to support the circular plastics economy by reinforcing to consumers the value of their 100% recyclable plastic bottles and caps and ensuring they don’t end up as waste in oceans, rivers or landfills. This program is being executed in conjunction with two of the country’s most prominent environmental nonprofits and the leading investment firm focused on the development of the circular economy. The World Wildlife Fund (WWF) will provide strategic scientific advice to help measure the industry’s progress in reducing its plastic footprint and The Recycling Partnership and Closed Loop Partners will assist in deploying funds for the initiative.

“Our industry recognizes the serious need to reduce new plastic in our environment, and we want to do our part to lead with innovative solutions. Our bottles are designed to be remade, and that is why this program is so important. We are excited to partner with the leading environmental and recycling organizations to build a circular system for the production, use, recovery and remaking of our bottles. Every Bottle Back will ensure that our plastic bottles are recovered after use and remade into new bottles, so we can reduce the amount of new plastic used to bring our beverages to market. This is an important step for our industry, and it builds on our ongoing commitment to protecting the environment for generations to come.”

Katherine Lugar, president and CEO of the American Beverage Association (ABA)

The Every Bottle Back initiative, spearheaded by ABA, will:

- Measure industry progress in reducing the use of new plastic in the United States through a collaboration with ReSource: Plastic, WWF’s corporate activation hub to help companies turn their ambitious plastic waste commitments into meaningful and measurable progress by rethinking the way plastic material is produced, used and recycled. Specifically, ABA will use the ReSource: Plastic accounting methodology to track on the collective progress made on executing strategies to reduce the use of new plastic as well as a resource in identifying additional interventions.

- Improve the quality and availability of recycled plastic in key regions of the country by directing the equivalent of $400 million to The Recycling Partnership and Closed Loop Partners through a new $100 million industry fund that will be matched three-to-one by other grants and investors. The investments will be used to improve sorting, processing and collection in areas with the biggest infrastructure gaps to help increase the amount of recycled plastic available to be remade into beverage bottles.

- Launch a public awareness campaign to help consumers understand the value of 100% recyclable bottles through community outreach and partner engagement and reinforce the importance of getting these bottles back, so they can be remade into new bottles. According to a poll conducted by Public Opinion Strategies (POS) on behalf of ABA, nearly half of consumers were unaware that America’s leading beverage companies are already making bottles that are 100% recyclable, including the caps.

- Work together to leverage our packaging to remind consumers that our bottles are 100% recyclable and can be remade into new bottles. Beverage companies will begin introducing voluntary messaging on packages beginning in late 2020.

“Reaching our goal of No Plastic in Nature by 2030 will only happen if business, governments and the NGO community work together to fix a broken plastic material system. ABA is driving this sense of collaboration within the beverage industry to address one critical piece within this system, which is PET recycling in the U.S. Measured by our ReSource: Plastic footprint tracker, the efforts made through Every Bottle Back will be met with data-driven solutions to ensure that real progress is being made. We hope the ambition raised by this initiative will inspire other industries to follow suit within the broader effort to stop plastic waste pollution.”

Sheila Bonini, senior vice president of private sector engagement at WWF

“The beverage industry cannot deliver on its promises of sustainable packaging without serious improvements to the current U.S. recycling system. Working in partnership with the beverage industry on its Every Bottle Back initiative will help to improve local recycling and provide Americans with stronger recycling programs for all materials, including plastic bottles. We applaud ABA’s members for launching meaningful, measurable work.”

Keefe Harrison, chief executive officer of The Recycling Partnership

“The leadership exhibited by The Coca-Cola Company, PepsiCo and Keurig Dr Pepper provides the investment necessary to optimize recycling in these cities and states. This partnership will serve as a model for the effectiveness of industry collaboration in modernizing recycling infrastructure and driving a reduction in the use of virgin plastic.”

Ron Gonen, chief executive officer of Closed Loop Partners

The majority of plastic beverage containers in the United States are made from polyethylene terephthalate, or PET, a strong, lightweight and safe plastic approved by the U.S. Food and Drug Administration (FDA) for use in food and beverage containers. It is unique, and because of its quality and versatility, recycled PET for years has been in high demand for use in an array of products as varied as clothing, carpets and playground equipment. Through the Every Bottle Back initiative, beverage companies are stepping up efforts to reclaim as much plastic packaging as possible to ensure it is remade into new PET bottles.

These efforts support other sustainability efforts underway by The Coca-Cola Company, PepsiCo and Keurig Dr Pepper.

“We’re proud to come together with our competitors to address the serious issue of plastic waste in our environment. We know we cannot do this alone and, in order to meet our goals and those of our industry, we need to work in partnership to drive collective action to ensure our bottles have second, third and fourth lives through continued recycling and re-use.”

James Dinkins, president, Coca-Cola North America

“At PepsiCo, we are striving to build a world where plastics need never become waste. We are proud to collaborate with others in the industry and respected partners to advance that vision and to do the hard work needed to educate consumers, enable collections and inspire action to recycle our plastic bottles. More recycled plastic lessens the need for new plastic.”

Kirk Tanner, chief executive officer, PepsiCo Beverages North America

“We have seen the meaningful impact this industry can have when we collaborate, and we are proud to be partnering to reduce our collective use of new plastic, while increasing the recycling and reuse of our 100% recyclable bottles. The Every Bottle Back initiative supports KDP’s top environmental priority to reduce packaging waste, as we work to support a circular economy with strong collective action.”

Derek Hopkins, chief commercial officer, Keurig Dr Pepper

Learn more about the Every Bottle Back initiative at www.EveryBottleBack.org. To schedule an interview, please contact the ABA press office at [email protected].

Team Spotlight: Allison Shapiro, Executive Director

Allison joined the Closed Loop Partners team this year and is responsible for strategic partnerships, capital formation, and fund structuring at the firm. We sat down with her to hear more about her journey into the circular economy world where profitability and sustainability meet.

I was ready to transition to a role where I could enable systemic change in a work environment where risk-taking was encouraged. I had already decided the circular economy was the right next sector — it was a matter of finding an exciting role that would blend investing, industry influence, and a triple-bottom-line ‘systems thinking’ manner of evaluating problems.

Tell us a little bit about your previous life and what brought you to Closed Loop Partners?

As a college student, I became excited by the possibility of capital markets enabling social and environmental change across national borders. I was a student at Georgetown University’s Foreign Service School studying Science & Technology Policy. I loved everything involved with social and environmental finance: from measuring impacts, to pricing them, to setting up schemes to finance and trade them, all with the goal of finding the most most efficient ways to protect and enable them.

After graduating, I became a carbon markets analyst at a D.C.-based non-profit, studying and reporting on voluntary carbon market trading regimes around the world. At the time, the economy was booming; there were several cap and trade bills in the U.S. Congress; and a carbon price seemed imminent — we could finally decouple greenhouse gas intensity from economic growth! Alas, the financial crisis happened the following year — and with it, so did the near term prospects for a national carbon price.

So, I returned to school in 2009 to study finance and the business of sustainability at the University of Michigan’s Erb Institute, receiving an MBA and an MS in sustainable systems science. After graduating in 2012, I joined JPMorgan in a rotational management training program. Following the program, I became a structured finance banker to alternative investment funds, creating custom financing solutions for alternative investment funds. I enjoyed the product development and also the sophistication of my clients. Most interesting of all, I was seconded to JPM’s Sustainable Finance team for part of my last year at JPM to set up two social impact funds.

After these secondments, it became clear that I was ready to transition to a role where I could enable systemic change in a work environment where risk-taking was encouraged. I had already decided the circular economy was the right next sector — it was a matter of finding an exciting role that would blend investing, industry influence, and a triple-bottom-line ‘systems thinking’ manner of evaluating problems. Having become aware of Closed Loop Partners (CLP) through friends in impact investing two years earlier, the decision to join was an easy one. We’re at a tremendously exciting phase in our platform growth, and I am thrilled to be a part of it.

What excites you most about the circular economy?

Two things: the urgency of the waste / conservation problem, and the fact that circular economy solutions make so much sense! Also, I’ve been obsessed with recycling since college. I even went ‘dumpster diving’ for a month on Georgetown’s campus to try to figure out the right combination of bin siting and labeling that would encourage people to recycle. Yeah, I was cool.

What are you most looking forward to in your role at Closed Loop Partners?

Being able to apply my finance and systems analysis experience to helping Closed Loop Partners grow. The impact, network, and respect that CLP has built in the recycling, sustainability, and impact investing industries is impressive.