How AI Could Change the Way We Think About Recycling

September 11, 2023

Closed Loop Partners’ Center for the Circular Economy and the NextGen Consortium launch a new study with AI technology company Greyparrot to analyze the composition of polypropylene in recycling streams

Behind the walls of recycling facilities across the U.S., a sea of materials moves through hands and machines working hard to get them to the end of the line––and the beginning of their next life. A critical balance of manual labor and automation enables the sorting and recovery of these materials in a closed loop system. Yet despite a multi-step sortation process, it is difficult to track what flows through the system at all times. It’s a challenge that results in many recycled materials losing potential value, in addition to millions of dollars worth of valuable material being sent to landfill unintentionally.

Among the diverse materials flowing through the recycling system are the yogurt containers, and iced coffee and fountain beverage cups many of us use on a regular basis. These are just a few examples of products made of one of the most commonly used resins in foodservice packaging today: polypropylene (PP). PP is a valuable material that should be kept in circulation to reduce waste and meet corporate commitments to use more recycled content in foodservice packaging. With that said, very little mechanically recycled food-grade PP actually cycles back into food-grade applications. Most end up in nonfood-grade applications that limit their value and the number of times they can be reused. To create a more circular path for food-grade PP, we must first answer the question: what is in the PP stream today, and how much of it is food-grade or clear food-grade PP?

The NextGen Consortium is a multi-year industry collaboration addressing single-use foodservice packaging waste by advancing solutions across material innovation, reuse and recovery infrastructure––and it’s working to answer that question. In the fall of 2022, the Consortium partnered with Resource Recycling Systems to examine PP bales in two materials recovery facilities (MRFs) to learn what was inside. While only a snapshot in time, the results were enlightening.

On average, nearly half of the PP bales (48%) were presumed food-grade, and more than a quarter of the bales were clear food-grade (26%). Clear beverage cups represented 14% of the bale on average. The high percentage of food-grade PP suggested that there is untapped value in the PP stream. A better system is required to ensure food-grade and/or clear food-grade PP is properly sorted into a separate bale at some point in the value chain if we are to retain its highest potential value.

This year, the NextGen Consortium is diving even deeper, launching a first-of-its-kind study leveraging artificial intelligence (AI) to analyze the composition of the PP material stream well before it ends up in a bale. Together with its managing partner––Closed Loop Partners’ Center for the Circular Economy––the NextGen Consortium is working with Greyparrot, a leading AI waste analytics platform for the circular economy. The collaboration aims to track and categorize objects in the PP stream, and determine the volume of valuable food-grade material passing through the system. AI is on the rise as one potential means of increasing visibility into the recycling process. Today, more technologies are needed to handle an increasingly mixed stream of collected materials, including plastics, electronics, textiles and food scraps––and to enable the recovery of clean, high-quality materials.

“Ensuring that recovery infrastructure can keep pace with a rapidly growing and diverse material stream is critical to advancing the circular economy, alongside solutions such as material innovation, reduction and reuse,” said Kate Daly, Managing Director and Head of the Center for the Circular Economy at Closed Loop Partners. “An important part of our work in the NextGen Consortium is identifying opportunities for data collection and analysis that can advance the circularity of foodservice packaging, and drive greater value for stakeholders across the system, including brands, innovators, infrastructure operators and consumers.”

As part of this project, the Greyparrot Analyser units will be installed above the PP recovery conveyor belts at four leading U.S. MRFs: Balcones Recycling, TX; Cougles Recycling, PA; Rumpke Recycling, OH; and Eureka Recycling, MN. Greyparrot’s AI-powered computer vision system uses cameras to capture images of objects in the PP stream, aiming to quantify and qualify the materials flowing through the MRFs. Their AI model will look to categorize each object based on material, format, financial value and brand, as well as distinguish food- and nonfood-grade material, using those images. Their units will then send that data to an analytics dashboard in real-time. Through machine learning, the flexible vision systems can help improve their package recognition and classification over time.

“We use artificial intelligence to gain continuous and reliable visibility into recycling streams,” said Ambarish Mitra, Co-founder and CPO of Greyparrot. “This helps us improve recycling operations by placing waste intelligence into the hands of the people who are recovering, redesigning and remanufacturing the objects we throw away. We are thrilled to work with our U.S. partners towards our vision of a future where every piece of waste is valued as a resource.”

The collaborative project––a first of its kind in North America––will run for more than six months. During that period, it will gather data on the composition of PP bales over time, while accounting for seasonality. That insight can help determine the potential untapped value in these streams, and identify other materials that might be coming through unintentionally. This data can also help shed light on the presumed volume of food-grade material being captured in the system, along with opportunities for recovery and separation into distinct value chains. More broadly, this can advance a circular economy for valuable materials, improve material quality delivered to recycling facilities, and enhance the value of recyclable commodities shipped to U.S. end markets.

“A lot is unknown about the curbside polypropylene stream today. Filling these knowledge gaps can increase the pace of development for material recovery. Understanding the composition of the stream in a large-scale study highlights potential, reduces risk for pioneers and accelerates better design implementation. This study will be the catalyst to developing much larger-scale recycling of polypropylene,” said Curt Cozart, President of Common Sense Solutions and Technical Advisor to the project.

PP cup recovery––alongside material innovation, reuse and fiber cup recovery––is a critical focus for the NextGen Consortium. According to The Recycling Partnership, more than 2 billion pounds of PP are generated every year by single-family households in the U.S. If just 30% of this material were recovered, it would reduce greenhouse gas emissions by over 300,000 metric tons, providing over 600 million pounds of valuable raw material to companies with recycled content commitments for their foodservice packaging, both voluntary and mandated.

The NextGen Consortium has been actively involved in PP recovery since 2021, when it joined The Recycling Partnership’s Polypropylene Recycling Coalition as a Steering Committee member. Through this initiative, the group helps to fund equipment grants for MRFs so that they can effectively capture PP packaging, and improve community recycling access rates. In addition to improving recycling access, the NextGen Consortium is committed to driving recycling rates by supporting the recovery of post-consumer recycled content (PCR) that can be re-incorporated into packaging.

This collaboration with Greyparrot and MRFs across the U.S. is one critical step toward achieving the NextGen Consortium’s goals. As more data about the PP material stream is captured over the next six months, the Consortium will analyze the new data, identifying opportunities to improve PP sortation and recovery into higher value, new food-grade applications and areas where more research is needed. The NextGen Consortium continues to invite additional MRFs to participate in the project, to gain a better understanding into what is flowing through their material streams and identify ways to drive more value to the system.

About the NextGen Consortium

The NextGen Consortium is a multi-year consortium that addresses single-use food packaging waste globally by advancing the design, commercialization, and recovery of food packaging alternatives. The NextGen Consortium is managed by Closed Loop Partners’ Center for the Circular Economy. Starbucks and McDonald’s are the founding partners of the Consortium, with The Coca-Cola Company and PepsiCo as sector lead partners. JDE Peet’s, Wendy’s and Yum! Brands are supporting partners. The World Wildlife Fund (WWF) is the environmental advisory partner. Learn more at www.nextgenconsortium.com.

About the Center for the Circular Economy at Closed Loop Partners

Closed Loop Partners is at the forefront of building the circular economy. The company is comprised of three key business segments: Closed Loop Capital Management, the Center for the Circular Economy and Circular Services. In 2018, Closed Loop Partners launched its innovation center, the Center for the Circular Economy, which unites competitors to tackle complex material challenges and to implement systemic change that advances the circular economy. Closed Loop Partners brings together designers, manufacturers, recovery systems operators, trade organizations, municipalities, policymakers and NGOs to create, invest in, and support scalable innovations that target big system problems. Learn more about the Center’s work here.

Reuse

Making Reuse an Everyday Reality: 3 Things We Must Consider Before Scale

September 06, 2023

Reuse is now at a critical stage of development. A plethora of innovation has expanded the realm of possibilities, but what will it take to get to the point of industry-scale disruption?

Earlier this year, seven winners of the highly anticipated 2023 Reusies were announced on stage at GreenBiz’s Circularity23 Conference in Seattle. The winners encompassed corporate and community initiatives, and B2B and B2C reuse innovations across food & beverage, consumer packaged goods and fashion & apparel. Together, they provided a window into the best and brightest developments in the reuse space. Indeed, hundreds of start-ups and large corporates are working on making reuse an everyday reality for consumers, with applications as far-ranging as closed system solutions for corporate campuses and events, to software companies supporting reuse-as-a-service, and refill applications in retail or in commercial, industrial and event spaces. The potential for reuse to reduce waste has catalyzed much innovation and brought conversations to a fever pitch.

Reuse is now at a critical stage of development. A plethora of innovation has expanded the realm of possibilities, but what will it take to get to the point of industry-scale disruption? Making reuse a far-reaching and everyday reality––where reusable items are consistently and efficiently reused to make a significant difference and reduce environmental impact––requires continued testing, collaboration across the value chain, investment and supportive policy.

At Closed Loop Partners, reuse systems are an integral part of our vision of a transition away from the take-make-waste economy and toward a circular economy. When products that have historically been single-use are able to be used two, five, ten or one hundred times, and the proper recovery infrastructure is in place for their eventual end-of-life, that can make a meaningful difference on reducing valuable materials sent to landfill––and on the embodied carbon, water and materials required to produce the item in the first place.

But to get to this next horizon, a number of factors must be considered to ensure that reuse does not result in unintended consequences and instead serves a truly circular economy:

1. Closed or semi-closed reuse systems are a key starting point, especially at early stages of adoption. On-premise reuse unlocks higher return rates which can make reuse systems profitable––or at least breakeven. In open systems, as consumers use and dispose products away from point of adoption, more complex collection networks and communication strategies are needed to drive returns. For this reason, closed systems can operate with lower upfront capital expenditures and lower recurring operating expenditures until the time at which consumer behavior has shifted to be more amenable to open systems (see #3!).

2. Reuse is a hardware-first business, and requires capital and collaborations to build localized infrastructure––including collection, sorting and washing. There continues to be a shortage of washing infrastructure needed for reuse solutions, and traditional waste management players are not currently set up for the type of collection and sorting needed for reusable products that are intended to stay in circulation for more than one use. Many software-only solutions still require partnerships with washers and logistics providers. There is an opportunity for founders, corporates and municipal governments to build out these partnerships to enable reuse and share in the funding that will be required to build this new infrastructure.

3. Broad consumer adoption starts with meeting customers where they are today. There are still many customers that have yet to be onboarded into the reuse culture. As we’ve seen in our work through the Beyond the Bag Consortium and the NextGen Consortium, we need to design solutions with current behaviors in mind and support customers as they build new habits. Advancing reuse won’t happen overnight; cross-industry and cross-company collaboration, a range of solutions, clear messaging and consistent regulatory frameworks are required to effectively support consumers in adopting reuse within their communities, as the industry addresses complex waste challenges. Importantly, in-market testing plays a key role in unlocking what works effectively in the market and meets customer needs. Today’s market is complex, with diverse customer demographics and shopping habits, different operations across retailers, a range of reuse packaging materials and more that need to be considered.

We see experimentation as a critical precedent to scale. Reuse is no simple feat, and testing market fit and operation alignment is an important step to expand reuse responsibly and mitigate unintended consequences that can happen without a measured examination of new systems. But isolated, small-scale experiments will not get us there. Closed Loop Partners runs multi-brand reuse tests through its Center for the Circular Economy to identify tactics that are proven and ready to scale, as well as models that require further tweaking and iteration to deliver the expected environmental and financial outcomes. While we work to scale proven solutions, we continue to de-risk systems that need refinement. Our in-field deployments intentionally mimic large-scale, cross-brand implementation, but in a controlled manner. The insights and data gleaned from these tests are key stepping stones to new rounds of implementation and scale. Most recently, the Beyond the Bag Consortium’s largest multi-brand reusable bag pilots tested a range of reuse solutions to understand what it will take to effectively drive reduction of single-use plastic bags. Next year, the NextGen Consortium will go back into market to test the viability of reusable cup systems across multiple brands. These tests unlock important insights on what it will take to build a culture of reuse and will serve as the foundation for identifying scalable initiatives.

With all these developments, we believe we’ll get there. There are tremendous tailwinds supporting the development of reuse and a multitude of communities, innovators and corporations committed to seeing the shift through. To do so, the next five years are critical to pivot from bespoke solutions to shared frameworks, from ad hoc consumer engagement to a consistent drumbeat, and from in market tests to truly scaled solutions. We are excited to be working to advance the transition from innovation to scaled solutions that can replace single-use. Join us!

This article represents perspectives from across Closed Loop Partners, including the Center for the Circular Economy and Closed Loop Capital Management. Special thanks to Kate Daly, Carol Lobel, Danielle Joseph, Aly Bryan and Anne-Marie Kaluz for sharing their thoughts for this piece.

How Closed Loop Partners’ Multi-Million Dollar Investment in LRS Is Expanding Recycling Infrastructure and Access in Chicago

August 16, 2023

This is Closed Loop Partners’ third loan to LRS, which will support the Exchange, its newly constructed materials recovery facility, accelerating materials circularity in the third largest city in the U.S.

When Closed Loop Partners provided its first loan to LRS almost 10 years ago, the leading recycling company was already making waves to advance materials circularity in the Chicagoland area. Operating in the third largest city in the U.S., home to 2.7 million people, LRS has faced significant opportunity to recover valuable materials and expand recycling access at scale, and has been at the forefront of this work, strengthening the recycling infrastructure needed to advance the circular economy. Over the last several years, LRS made critical advancements in its growth, supported by catalytic capital from circular economy investment firm, Closed Loop Partners. Today, LRS, the largest recycling company in the Chicagoland area, has reached another pivotal moment of growth: a newly constructed materials recovery facility (MRF) in the heart of Chicago, the Exchange. Supporting the newly constructed MRF, and the innovative technology housed within it, is a multi-million dollar loan from Closed Loop Partners’ Infrastructure Group.

The Closed Loop Partners team at LRS’s ribbon cutting ceremony; photo credit: Closed Loop Partners

Pictured left to right: Jennifer Louie (CLP), Kate Krebs (CLP), Ray Hugel (CLP)

The state-of-the art MRF is now operational and expected to divert 224 million pounds of recycled material per year. It will house cutting-edge system components, including new artificial intelligence (AI)-powered equipment and other technologies to advance efficient materials sortation and recovery in the Chicagoland area. The loan is closing at a critical time, as infrastructure upgrades and innovative technologies are needed to handle an increasingly mixed stream of collected materials, including plastics & packaging, textiles and food scraps. AI and automation play an important role in improving material sortation and reducing contamination across different material streams, enabling the recovery of clean, high-quality materials. The AI-powered sortation technology to be integrated at the Exchange will enable LRS to sort polypropylene (PP) plastic for the first time in the Chicagoland area, including cold to go cups and yogurt containers. The new automated technology is also expected to mitigate labor risks at the facility, as well as add new jobs to manage the new equipment––increasing job quality and safety.

LRS Exchange Facility – LRS employees celebrate the grand opening of The Exchange materials recovery facility, which created 50 new full-time jobs in the city; photo credit: Sean Kennedy/LRS

This is Closed Loop Partners’ third loan to LRS, building on a robust track record between the two entities. The investment firm’s first and second loans to the recycling company contributed to the growth of their operations at a critical moment, helping enable them to win the collection rights of recyclable materials in three additional Chicago Blue Cart recycling zones. This new loan, provided by three catalytic funds within Closed Loop Partners’ Infrastructure Group––the Closed Loop Infrastructure Fund, Closed Loop Circular Plastics Fund and Closed Loop Beverage Fund––helps expand LRS’s capacity, as the Exchange will process recyclable material collected from all six of Chicago’s Blue Cart zones, sorting material for approximately 430,000 households, encompassing over one million people. The Exchange’s expanded capacity will also enable LRS to collect material from other areas surrounding the city, reducing landfilling and providing recycling access for more communities.

“This is a key moment of our expansion, as we extend our reach and impact across the Chicagoland area,” says John Larsen, chief operating officer, LRS. “This loan to support our new facility helps us serve even more households in the area, and sort and process more valuable materials––including polypropylene, for the first time in the region. Closed Loop Partners has been a key part of LRS’s meaningful growth over the years and we are proud to work with their team again in this work to recycle even more valuable materials and reduce waste.”

Ribbon cutting ceremony for LRS’ new $50 million materials recovery facility (MRF) in Chicago, IL; photo credit: Sean Kennedy/LRS

Pictured left to right: Emily Olsen-Torch (LRS), David Fass (Macquarie), Department of Streets and Sanitation Commissioner Cole Stallard, Rich Golf (LRS), Chief Operating Officer John Larsen (LRS), Cook County Commissioner John Daley, Executive Vice President John Silwicki (LRS)

Over the last nearly 10 years, Closed Loop Partners’ Infrastructure Group––the investment firm’s catalytic capital group––has played a key role in identifying and advancing novel technologies and infrastructure development to help private companies and municipalities keep more materials in circulation and out of landfills. Funded by many of the largest consumer goods, technology and material science companies, the catalytic strategy aims to accelerate further investment into materials circularity and drive net positive environmental and social outcomes. To date, the Closed Loop Infrastructure Group has helped keep approximately three million tons of material in circulation across 30 private loans and 15 municipal loans.

The loan to LRS is a milestone for Closed Loop Partners’ catalytic capital funds participating in the financing:

Aligned with the Closed Loop Infrastructure Fund’s goal to improve efficiencies in circular economy infrastructure, the loan to LRS will significantly expand processing capacity in the Chicagoland area;

Further aligned with the Closed Loop Circular Plastics Fund’s goal to advance the recovery and recycling of plastics, the new equipment at the Exchange will capture and separate PP from the stream, with an expected rate of 650 tons of PP collected per year;

Finally, as the Closed Loop Beverage Fund, in partnership with the American Beverage Association, aims to improve the circularity of PET, a critical plastic to the beverage industry, the loan will help reduce LRS’s residue rate in the Chicagoland area, which will enable an increase in other salable commodities annually, including PET for bottle-to-bottle applications. This investment is part of the beverage industry’s Every Bottle Back initiatve, an integrated and comprehensive partnership between America’s leading beverage companies––The Coca-Cola Company, Keurig Dr Pepper and PepsiCo––to reduce the industry’s use of new plastic. The loan is expected to unlock at minimum an additional 150 tons of PET per year.

“One of our industry’s highest priorities is to create a circular economy for our bottles and cans. We are taking action at every step to make sure they are remade as intended,” said Kevin Keane, interim president and chief executive officer of American Beverage. “Chicago is a great and innovative American city. It is exciting to partner on a significant project that will serve to enhance its beauty, environment and quality of life. America’s leading beverage companies are carefully designing our bottles to be 100% recyclable and investing in modern recycling systems to reduce our plastic footprint and keep plastic out of nature. We are excited to continue that work here in Chicago and thank everyone who made this investment a reality.”

“As the circular economy grows across North America, companies that are vital to its development require access to financing to upgrade technology and expand capacity. Closed Loop Partners’ Infrastructure Group is proud to support leading private and public organizations advancing material circularity through upgraded infrastructure and innovative technologies,” says Jennifer Louie, Managing Director of the Closed Loop Infrastructure Group at Closed Loop Partners. “LRS has been a leader in developing the infrastructure needed to accelerate materials circularity in the Chicagoland region. We are thrilled to be working with their team to advance circularity in one of the largest cities in the U.S., keeping more materials in circulation and serving more communities.”

As LRS enters its next phase of growth, Closed Loop Partners will work closely with the LRS team to integrate new technologies into the facility and bolster potential end markets for materials recycled by the facility, helping establish more robust circular systems in the region.

Learn more about Closed Loop Partners’ catalytic capital strategy here.

Disclaimer:

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Capital Management or any company in which Closed Loop Capital Management or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Closed Loop Capital Management does not utilize its website to provide investment or other advice, and nothing contained herein constitutes a comprehensive or complete statement of the matters discussed or the law relating thereto. Information provided reflects Closed Loop Capital Management’s views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision. Certain information on this Website may contain forward-looking statements, which are subject to risks and uncertainties and speak only as of the date on which they are made. The words “believe”, “expect”, “anticipate”, “optimistic”, “intend”, “aim”, “will” or similar expressions are intended to identify forward-looking statements. Closed Loop Capital Management undertakes no obligation to update publicly or revise any forward-looking statements, whether as a result of new information, future developments or otherwise. Past performance is not indicative of future results; no representation is being made that any investment or transaction will or is likely to achieve profits or losses similar to those achieved in the past, or that significant losses will be avoided.

The testimonials provided are from current clients and Limited Partners of Closed Loop Partners. No compensation was provided for the statements, and the statements do not present any material conflicts of interests.

Molecular Recycling

What Is Chemical Recycling, Why Does It Have So Many Different Names, and Why Does It Matter?

August 15, 2023

Closed Loop Partners spent 18 months investigating the environmental impacts and financial viability of several types of molecular recycling technologies (sometimes also called advanced recycling or chemical recycling) to understand how and if these diverse technologies can fit into a circular future for plastics. Here’s what we found.

- Molecular recycling is a diverse sector that can be categorized into three distinct technology categories: purification, depolymerization and conversion.

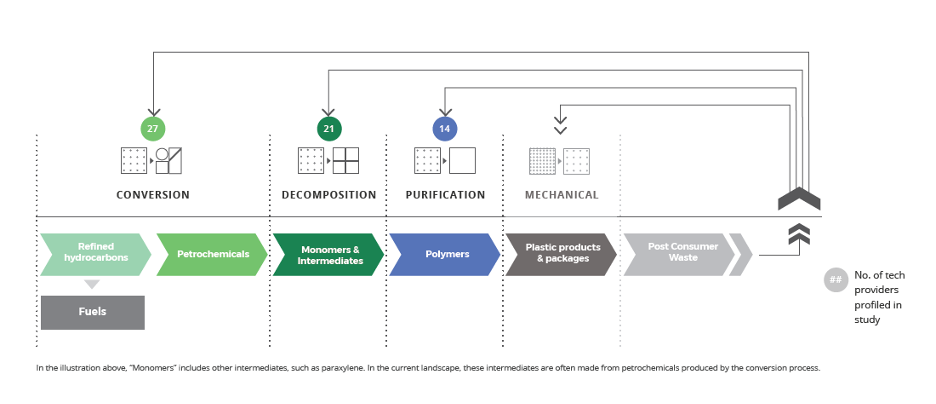

Figure 1: Molecular Recycling Technology Categories and Their Outputs

Molecular recycling is a broad umbrella term – also referred to as chemical recycling or advanced recycling – that encompasses dozens of technologies that use solvents, heat, enzymes, and even sound waves to purify or break down a wide range of plastic feedstocks to create polymers, monomers, oligomers or hydrocarbon products so that they can re-enter manufacturing supply chains, instead of going to landfill.

In other words, molecular recycling technologies can break down plastic waste into its constituent building blocks, which can then be used to create new plastic products. These technologies are only circular when their supply chains produce a final product. Converting plastics to fuel is not recycling or circular. Molecular recycling is a group of technologies that can complement mechanical recycling and help widen the aperture of plastic waste that we can recycle today.

- Molecular recycling is only one part of a suite of solutions to address plastic waste; both upstream and downstream solutions are needed, including design and reuse, as well as mechanical and molecular recycling, and policy.

Figure 2. The suite of solutions needed to reduce plastic waste

Molecular recycling is part of a suite of solutions needed for a circular plastics economy. It is not a silver bullet but plays an important role in creating a waste-free future for our hardest-to-recycle plastics which include the 41 million metric tons of textiles and approximately 2,000 wind turbine blades expected to go to landfill in the U.S. every year.

- Expanding the scope of plastics that we recycle is important given the diversity of plastics in our economy. We will not achieve a waste-free future unless we scale solutions that address all plastics.

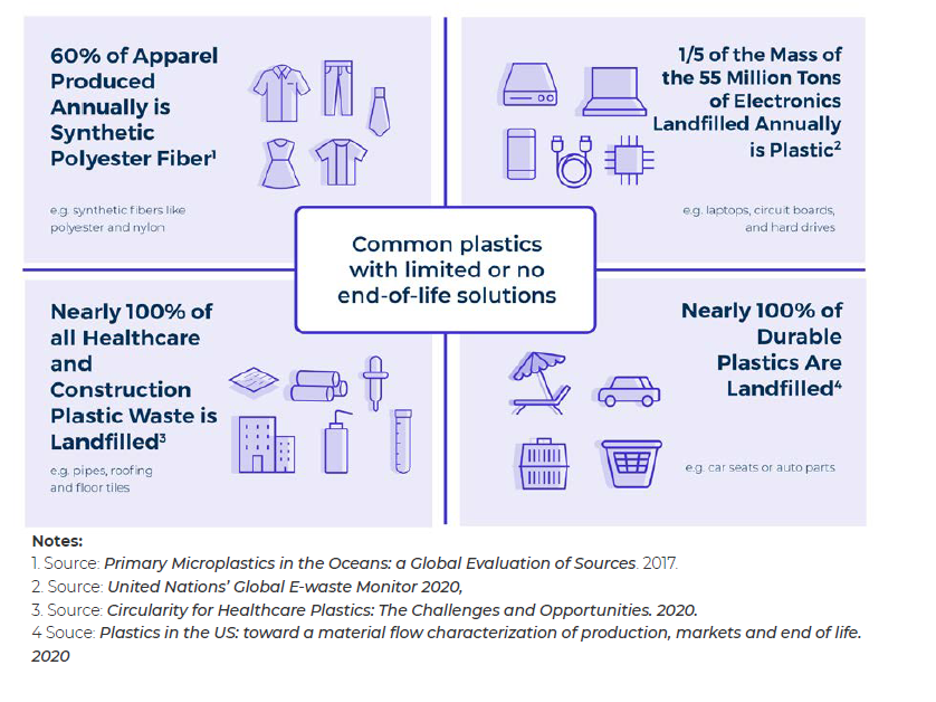

Figure 3. Common Plastics Without Commercial Recovery Solutions, Typically Sent to Landfill every year

The “plastics waste crisis” has been defined in the public and policy discourse as created by single-use plastics. Yet, two-thirds of plastics put into use in the U.S. today are used for purposes other than single-use packaging. These types of plastics are equally visible and challenging to recover and reuse.

- Molecular recycling can expand the scope of plastic waste we can recycle, helping to preserve the value of resources in our economy.

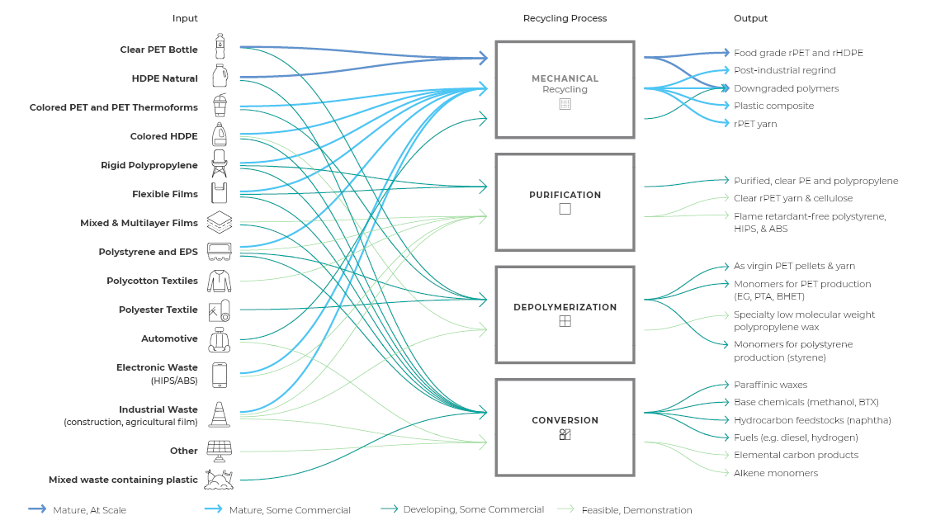

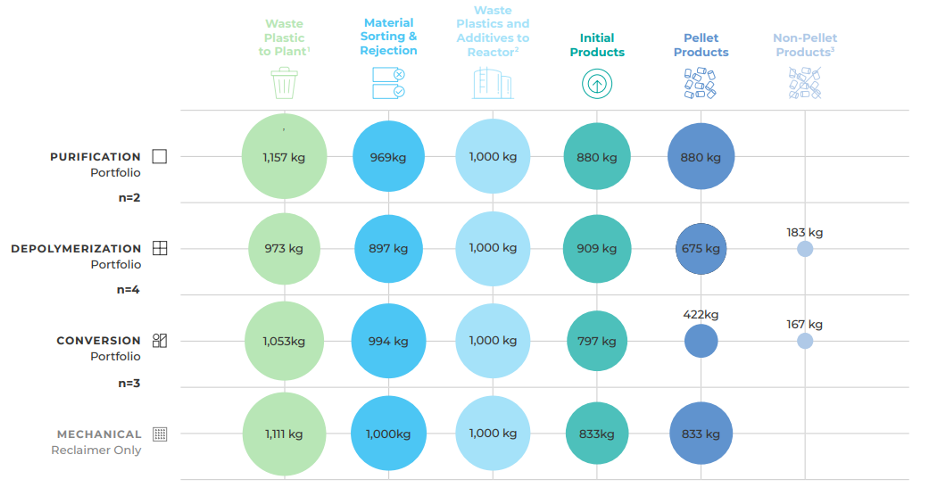

Figure 4: Inputs and outputs for mechanical, purification, depolymerization and conversion technologies from input to output.

Plastic is as ubiquitous as it is diverse. Our current mechanical recycling system is designed to address only a small fraction of plastics in the market – namely, plastic water bottles (PET), milk jugs (HDPE), and in some markets, yogurt cups (rigid polypropylene). Plastic packaging, like plastic film (LDPE) and clear boxy packaging that many salad mixes are sold in (PET thermoforms) are sometimes downcycled into plastic lumber. Textiles and durable plastics are recycled in lower quantities or not at all because there is less consistent demand for these recycled plastics. As a consequence, most plastic waste ends up in landfill.

Molecular recycling technologies can widen the aperture of plastic waste that we can recycle today beyond packaging. Purification technologies can process electronic waste and films. Depolymerization technologies, which largely focus on PET and polyesters, are a critical recycling solution for synthetic textiles including carpets and athletic clothing. Conversion technologies like gasification can even take mixed waste, breaking down feedstock to basic carbon and hydrogen atoms.

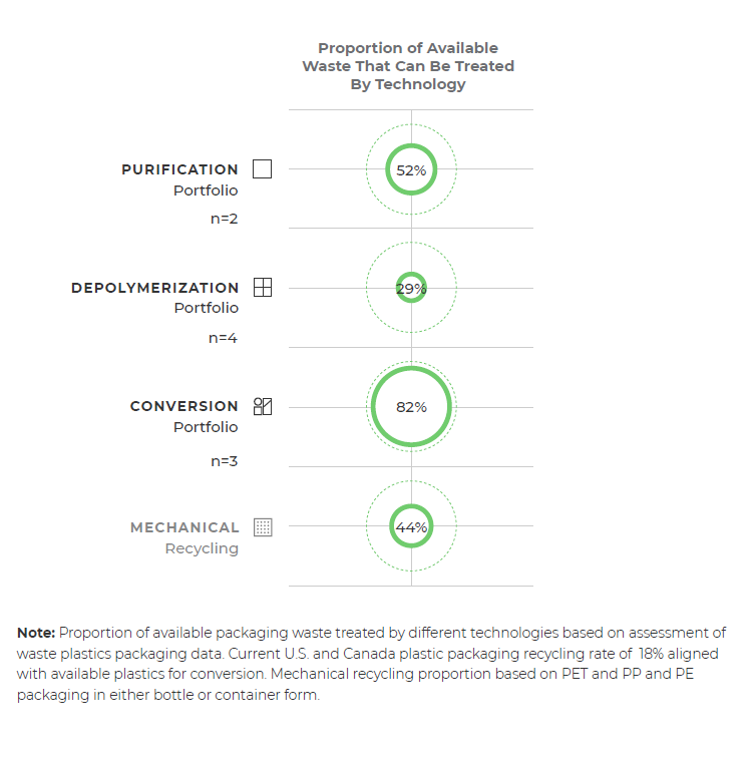

- Conversion technologies like pyrolysis and gasification can process the highest volume of plastic packaging and can accept mixed plastic packaging feedstock.

Closed Loop Partners evaluated nine different technology processes across the three technology categories. When evaluating the total packaging volumes across the United States and Canada, we found that the conversion technologies could accept 82% of all plastic packaging produced, which is more than mechanical, purification, or depolymerization technologies could address alone. These types of technologies also can process mixed plastic waste, while purification and depolymerization requires a sorted and single-resin feedstock. Because feedstock can be mixed, conversion technology companies are often paid to take feedstock rather than paying for feedstock.

Figure 5. Percent of US and Canadian Plastic Packaging that Closed Loop Partner’s Cohort of Molecular recycling Technologies could Address

- When considering downstream solutions, a critical metric of success is the amount of recycled plastic (PCR) that each technology solution can produce. The less a polymer is broken down through molecular recycling process, the more recycled plastic will be produced.

Each molecular recycling technology category has a distinct supply chain. For example, purification technologies produce finished recycled plastic. Depolymerization technologies produce monomers which would be sent downstream to be easily repolymerized back into plastic. Conversion technologies have the longest route back to becoming plastic. A pyrolysis technology company will produce pyrolysis oil which would be sent and processed by a steam cracker to produce monomers, which are then sent downstream to make plastic again.

Closed Loop Partners calculated how much plastic resin would be produced by each of the three main molecular recycling technologies discussed in this series (e.g., purification, depolymerization and conversion) if we were to put 1,000 kilograms of plastic feedstock into the technology reactor. Purification yielded the highest amount at 88% of material processing efficiency. Conversion technologies yielded the lowest amount of recycled plastic with a 42% processing efficiency. The capacity to move away from virgin plastics requires the recycling sector to be as efficient as possible.

Figure 6: Average mass yield when 1,000kg of plastic waste is put into each technology process

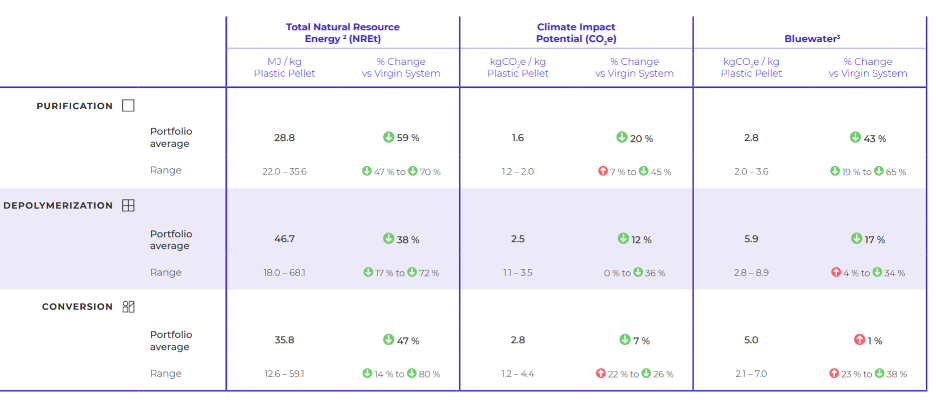

- From an environmental perspective, purification and depolymerization technologies have a smaller environmental footprint, on average, compared to conversion technologies.

Closed Loop Partners also analyzed the energy, greenhouse gases and water impacts of individual technology processes, and the systems-level impact of producing different polymers via purification, depolymerization and conversion technologies. On average, purification was the best performing category across all environmental measures, yielding 20% reduction in greenhouse gas emissions compared to the virgin plastics supply chain. Depolymerization had an average greenhouse gas reduction of 12%, while conversion technologies reduced carbon emissions by 7%, on average. Decarbonizing the plastics supply chain requires prioritizing the solutions that help to meaningfully improve the status quo.

Figure 7: Summary of environmental impacts to produce recycled plastic by technology category

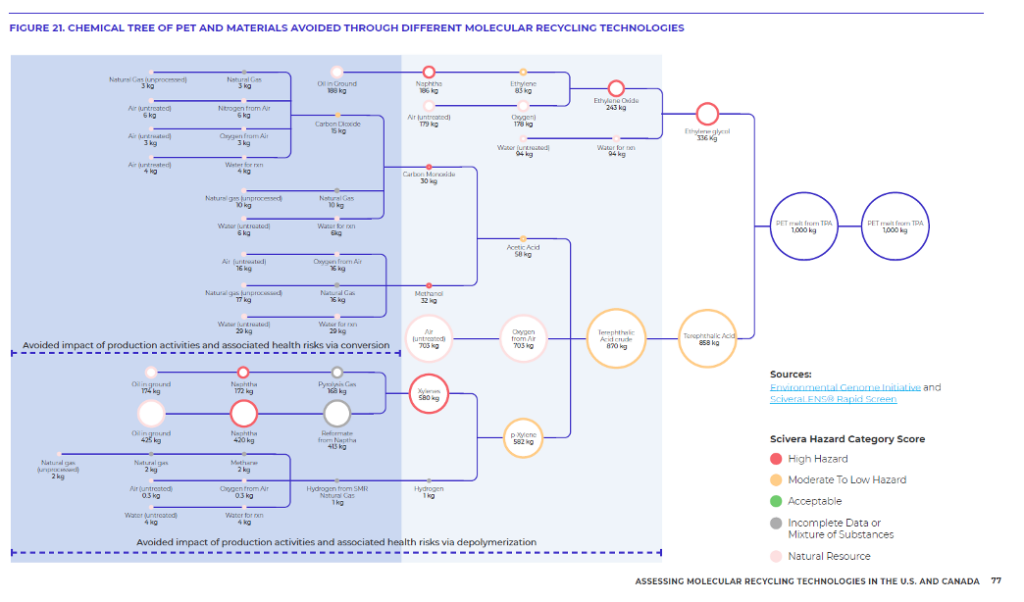

- The less a polymer is broken down through molecular recycling process, the fewer virgin petrochemical inputs are needed to make plastic again – which can reduce the human health impacts of plastic production compared to virgin plastic production.

Several chemical inputs are used to produce plastic. We’ve pictured the chemical tree to make PET which is the plastic used in water bottles. Because plastic can be recycled by many types of molecular recycle technologies, our team wanted to understand the potential human health impacts of different technologies. While qualitative in nature, our findings strongly suggest that the less a polymer is broken down through a molecular recycling process, the lower the human health risk because fewer chemicals and processing are

required to build back the polymer. In the illustration below, depolymerization technologies have an advantage over conversion technologies that can also process PET because depolymerization displaces more of the virgin supply chain to create an equivalent amount of plastic.

Figure 8: Summary of environmental impacts to produce recycled plastic by technology category

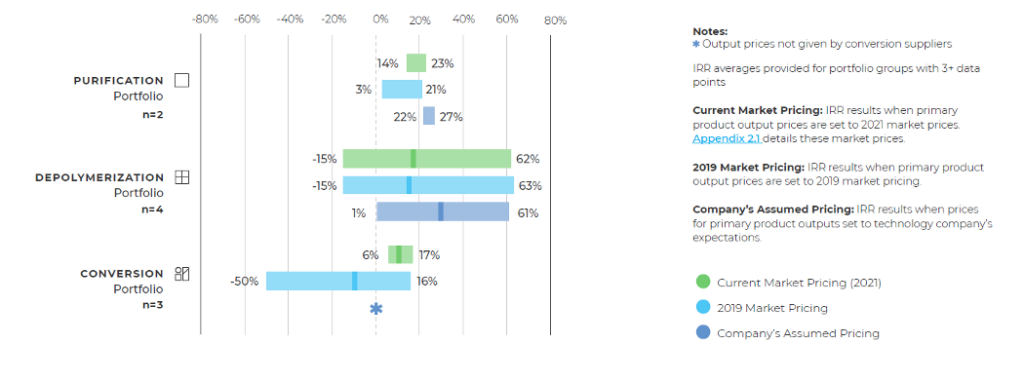

- The economic viability of molecular recycling technologies varies depending on several factors, such as the cost and accessibility of feedstocks and the market demand for the recycled products.

Analyses conducted by Closed Loop Partners over the course of 18 months across nine technology companies found that at least one technology company was financially viable in each category. Specifically, seven of the nine technology companies evaluated had a positive internal rate of return (IRR) ranging from 6% to 62% in the 2021 base case. It is also noteworthy that two-thirds of the technology companies in our study had positive IRRs, given that our base case assumes that these technologies are expected to sell their outputs at market commodity prices without a premium. Figure 5 above summarizes the expected rate of return across three scenarios: 2021 market pricing, 2019 market pricing, and the expected output pricing cited by the technology companies themselves.

Figure 5: Expected Internal Rate of Return (%) Ranges for Each of the Three Molecular Recycling Technologies

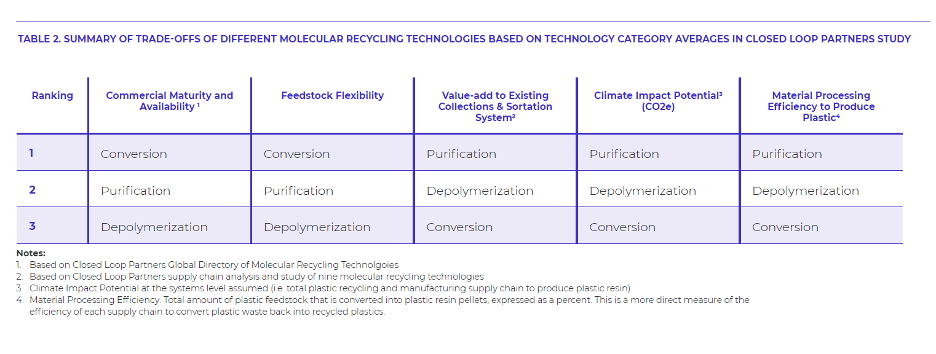

- There are tradeoffs to each molecular recycling technology category and type. The viability of one solution depends on those metrics that matter most to a brand, investor, or community.

The molecular recycling sector is incredibly nuanced and diverse. Not all technology groups are at the same level of development. Their tolerance for mixed plastics or other contamination varies company to company, just like their performance across environmental impact metrics like energy, water and greenhouse gas emissions. Due diligence prior to investing in strong performing technologies is critical. Closed Loop Partners has summarized the results when observing the category averages between purification, depolymerization, and conversion in the table below. This summary is based on our review of nine technology companies between 2020-2021 and should only serve as a point of data, not a definitive source on the state of the sector at large. The opportunity for consumer brands, policymakers, and investors is to collaborate to develop a vision of success for this sector.

To read our full report on molecular recycling technologies, including a list of more than 100 questions that investors and brands should ask when considering investing in this sector, visit Closed Loop Partner’s website.

The Most Sustainable Bag Is Likely the One You Already Own: 5 Things YOU Can Do to Reduce the Need for Single-Use Plastic Bags

July 19, 2023

How often do you get to the checkout counter only to realize you’ve left your reusable bags at home or in the car? It’s happened to all of us, including me.

Don’t be that person stashing plastic bags until your drawer begins to overflow. In addition to going bagless for quick shopping trips, here are 5 tips for remembering to bring your own bag, so YOU can reduce the need for single-use-plastic bags:

- Make it visible. Write “bring bags” at the top of your grocery list and leave bags in a basket near your front door or hanging on the doorknob, so you don’t forget them as you are leaving the house.

- Make it available. Always keep a few bags in your car for spontaneous shopping trips.

- Make it essential. Place an important item in the bag, like your phone, keys or wallet, so you won’t forget it.

4. Make it personal. Purchase reusable bags you actually like, so you’ll be more inclined to carry them with you.

Why is this so important? Every year, 100 billion single-use plastic bags are used annually in the U.S., and its estimated fewer than 10% of them are recycled.

While the convenience of the single-use plastic retail bag can’t be disputed, the negative impact — considering its short use (12 minutes, on average) and long estimated lifespan — has created an untenable situation that is contributing to a mounting global waste crisis. Plastics can now be found in the deepest depth of the ocean, the top of Mount Everest, and on both polar ice caps.

Reducing the number of single-use plastic bags retailers use across their stores can make a tremendous difference. Even a 1% bag reduction would have a substantial impact on our global waste footprint – equivalent to 1 billion fewer bags used and discarded across the U.S.

If you’re already regularly using reusable bags, you are not alone! Learn more about our pilots in Denver and Tucson where 150+ retailers are working together to help all of us reinforce the habit of bringing our bags. Additionally, check out our new playbook full of solutions retailers can implement today to get teams and customers on board with reducing single-use plastic bags and encourage shoppers to reuse their own bags.

While there’s a lot retailers can do; remember, we’re all in this together and YOU can make a difference by reducing the need for single-use plastic bags.

Dollar Tree and Family Dollar Join the Beyond the Bag Consortium

June 05, 2023

The retailer aims to reduce dependency on single-use plastic bags as a Supporting Partner in the Consortium

This May, Dollar Tree, Inc. announced its participation in the Consortium to Reinvent the Retail Bag as a Supporting Partner, alongside other leading retailers committed to reducing single-use plastic bag waste. The Consortium, managed by Closed Loop Partners, convenes leading retailers aiming to identify, test and implement viable design models to create a system that serves the function of the current retail bag, providing customers with convenient, accessible and environmentally-sound solutions. Dollar Tree and Family Dollar’s commitment to the Consortium supports their mission to make sure shoppers have the things they need in their everyday lives, and to create an experience that is uniquely convenient and affordable––while also helping reduce waste in the process.

By advancing and testing innovative solutions to reinvent the retail bag and reduce single-use plastic waste with the Consortium, Dollar Tree and Family Dollar are helping more communities gain access to less wasteful ways to bring goods home. The Fortune 200 company continues to make steps to reduce its environmental footprint, and this partnership in the Consortium is another key step toward its goals.

As a Consortium partner, Dollar Tree, Inc. will participate in the Consortium’s ‘Bring Your Own Bag’ Pilot in select cities to encourage customers to shop with reusable bags more frequently. The program also includes test strategies, such as signage, marketing and customer prompts to reinforce shopper behavior and ultimately reduce dependence on single-use plastic bags.

“At Dollar Tree and Family Dollar, we are working to ensure we play a responsible role in the communities we serve, as we bring more value and convenience to our customers,” says Jennifer Silberman, Chief Sustainability Officer of Dollar Tree. “A key part of this is ensuring that we are reducing our waste and environmental impact across our stores. We look forward to our partnership with the Beyond the Bag Consortium, as we work together to identify more sustainable and accessible solutions that serve the function of the current retail bag and reduce plastic waste.”

“Dollar Tree and Family Dollar’s participation as a Supporting Partner in the Beyond the Bag Consortium is another key milestone for expanding our collective impact,” said Kate Daly, Head of the Center for the Circular Economy at Closed Loop Partners. “Collaboration across sectors is a critical part of this effort. Their partnership not only further moves the needle across the retail industry, but will also increase access to less wasteful solutions to bring goods home in more communities across the United States.”

Why We Invested in Molg: Supporting the Circular Economy for Critical Minerals Through Electronics Recovery

May 31, 2023

This blog is part of our “Why We Invested” series, which offers a deep dive into our most recent investments and the growing circularity trends in the space.

Over the past few months, the dialogue around sourcing critical minerals for the clean energy transition has reached a fever pitch. In March, we highlighted the three pain points to critical mineral recovery that have been largely absent from discussions: (1) valuable streams of recoverable domestic materials are currently overlooked; (2) existing processing techniques are leaving value on the table; and (3) geographic silos are disadvantaging both suppliers of recovered materials and manufacturers. Today, we’re excited to share how one of the newest portfolio companies of Closed Loop Partners’ Ventures Group, Molg Inc., is moving the needle on critical mineral recovery through advancing design-for-disassembly and deconstruction.

Molg uses robotics and design software to ensure one product’s end is another’s new beginning––enabling a circular manufacturing process. Led by Co-Founders Rob Lawson-Shanks and Mark Lyons, Molg provides a full suite of solutions to improve the disassembly of existing electronic products––from servers to laptops to handheld electronics. We invested in Molg because circularity is at the core of why and how this team operates. They think outside the box of traditional, linear systems, understanding that just because products have always been designed one way, doesn’t mean that process should continue. They are also committed to recapturing as much material as possible––including those previously designed in non-recoverable ways––recognizing that even products lacking optimized designs can be recovered profitably at scale. That’s a circular economy.

- Molg is targeting a historically overlooked source of critical materials in the U.S.: end-of-life electronics. Much of the unused critical materials needed for advancing the clean energy transition are not domestically available at scale in the U.S. and may be sourced from regions challenged with human rights breaches, water scarcity or geopolitics. However, much of the minerals needed already exist in our end-of-life electronics in the U.S.––both in commercial and individual use cases. Molg is committed to capturing and recovering the materials from these sources and, through direct CAD integrations, has a pathway to do so for a diverse variety of products.

- Molg’s robotic disassembly processes maximize the value from recovered materials. Traditional recovery processes prioritize shredding materials and then using chemicals to deconstruct those materials down to monomers, capturing only those worth the highest value, and losing value in the process. By starting with disassembly, Molg can close a tighter loop––keeping still usable materials in their original form factor––and accelerating reuse while ensuring feedstock that can be recycled.

- Molg’s micro-factory approach allows for localized recovery where the materials are most needed––minimizing transport costs that may otherwise challenge recovery economics. End-of-life electronics are heavy and transporting them costs money. By advancing pathways to disassemble electronics on-site through their micro-factories, Molg allows processors to get to single source feedstocks sooner, removing the need for sortation and processing that may have required transport before recycling could take place.

What the Molg team is building is just one part of the broader recovery ecosystem. The involvement of the entire value chain is needed––from aggregators, sorting and recertification infrastructure, metal processors and manufacturers who are prepared to use recycled feedstocks in their processes. This also includes designers prepared to take on the challenge of designing for disassembly, and regulators who view these waste products as a primary source of materials and worthy of being prioritized. There is a promising opportunity ahead for critical minerals, and at Closed Loop Partners, we’ll continue to invest in companies that strive to push circularity for these materials forward.

Interested in learning more about Molg? Tune in to Circularity23 where the team will be pitching for Accelerate for Circularity!

About Closed Loop Partners

Closed Loop Partners is at the forefront of building the circular economy. The company is comprised of three key business segments. Closed Loop Capital Management manages venture capital, growth equity, buyout and catalytic private credit investment strategies on behalf of global corporations, financial institutions and family offices. The Center for the Circular Economy unites competitors and partners to tackle complex material challenges and implement systemic change to advance circularity. Circular Services employs innovative technology within reuse, recycling, remanufacturing and re-commerce solutions to improve regional economic and environmental outcomes, and build resilient systems that keep food & organics, textiles, electronics, packaging and more, in circulation and out of landfill or the natural environment. Closed Loop Partners is based in New York City and is a registered B Corp. For more information, please visit www.closedlooppartners.com.

About Closed Loop Ventures Group

Closed Loop Partners’ venture capital arm launched in 2017 with one of the first venture funds dedicated solely to investing in early-stage companies developing breakthrough solutions for the circular economy. The Closed Loop Ventures Group targets leading innovations in material science, robotics, agritech, sustainable consumer products and advanced technologies that further the circular economy.

The Closed Loop Venture Fund II builds on the venture capital group’s first fund’s strategy, supported by an existing portfolio with strong financial performance, coupled with robust environmental and social impact. HomeBiogas, one of the early investments of the Closed Loop Venture Fund I is a leader in developing biogas systems that transform organic waste into clean energy and bio-fertilizer. They announced their $94 million initial public offering (IPO) in Israel in 2021, accelerating the company’s growth into additional markets, including North America. To date, the company has sold over 10,000 systems in more than 100 countries. Algramo, another investment of Fund I, developed a reuse system powered by vending machines that dispense household products into smart reusable packaging. With the investment and support of Closed Loop Partners, the Chile-based company expanded into North America, now piloting their reuse systems in New York City, while also having piloted with leading brands such as Walmart and Unilever in other geographies.

About Molg Inc.

Molg tackles the growing e-waste problem by making manufacturing circular. The company’s robotic microfactory can autonomously disassemble and reassemble complex electronic products like laptop PCs, servers, and handheld electronics, helping keep more valuable materials within supply chains. Molg partners with leading electronics manufacturers to design the next generation of products with reuse in mind, ensuring that one product’s end is another’s beginning. To learn more, visit molg.ai.

Disclaimer:

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Capital Management or any company in which Closed Loop Capital Management or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Closed Loop Capital Management does not utilize its website to provide investment or other advice, and nothing contained herein constitutes a comprehensive or complete statement of the matters discussed or the law relating thereto. Information provided reflects Closed Loop Capital Management’s views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision. Certain information on this Website may contain forward-looking statements, which are subject to risks and uncertainties and speak only as of the date on which they are made. The words “believe”, “expect”, “anticipate”, “optimistic”, “intend”, “aim”, “will” or similar expressions are intended to identify forward-looking statements. Closed Loop Capital Management undertakes no obligation to update publicly or revise any forward-looking statements, whether as a result of new information, future developments or otherwise. Past performance is not indicative of future results; no representation is being made that any investment or transaction will or is likely to achieve profits or losses similar to those achieved in the past, or that significant losses will be avoided.

Sumitomo Mitsui Banking Corporation Invests $10 Million in Closed Loop Partners’ Circular Plastics Fund, Accelerating More Capital Toward Innovation and Infrastructure for Plastics Recovery and Recycling

May 30, 2023

NEW YORK, May 30, 2023 — Closed Loop Partners announced a $10 million investment in its Closed Loop Circular Plastics Fund from Japanese multinational banking and financial services institution Sumitomo Mitsui Banking Corporation (SMBC). The investment partnership aims to advance the recovery and recycling of rigid and flexible polyethylene (PE) and polypropylene (PP) plastics in the United States and Canada.

The Closed Loop Circular Plastics Fund is a key part of Closed Loop Partners’ broader strategy to reduce, reuse and recycle plastics in a circular economy. The fund focuses on PE, PP and flexible plastics––critical resin types that require additional investment to keep more material in circulation and help ensure that the industry’s demand for recycled material will be met. The fund provides catalytic debt and equity financing, spurring additional mainstream investments into recovery and recycling solutions and infrastructure that can help address bottlenecks in the recycling system. Fund performance is benchmarked according to a combination of financial and impact outcomes, including tons of PE and PP impacted, and tonnes of greenhouse gas emissions avoided or reduced.

With its investment, SMBC joins a group of leading corporate investors dedicated to the transition to a more circular economy for plastics, including Dow, LyondellBasell, NOVA Chemicals, Charter Next Generation, Chevron Phillips Chemical, SK geo centric Co. and SEE. This collaborative effort is key to advancing the recovery and recycling of plastics in the U.S. and Canada, at scale.

“SMBC is committed to sustainability, while identifying partnerships that leverage our expertise and strong footprint in the Japan and Asia Pacific region. Our team is proud to partner in the Closed Loop Circular Plastics Fund’s catalytic, impact-first effort to accelerate infrastructure, equipment, municipal services, as well as innovation and enabling technologies related to flexible films and specific plastic types,” said Masayuki Takanashi, Group Chief Sustainability Officer (CSuO) of Sumitomo Mitsui Financial Group, Inc. “Our commitment and partnership with Closed Loop Partners are part of SMBC’s steadfast commitment to our stakeholders, our local and international communities, the global environment, and the next generation.”

Since its launch in 2021, the Closed Loop Circular Plastics Fund has made several catalytic debt and equity investments to both private companies and public organizations, financing post-pilot scale projects that advance collection infrastructure, sortation capabilities, enabling technologies and re-manufacturing of PE and PP plastics, including:

- Equity investment in Greyparrot, a leading AI waste analytics platform that links to moving conveyor belts in sorting facilities to increase transparency and automation in recycling and help unlock the financial value of recycled materials;

- Loan to Myplas USA, a recycling company building a 170,000 square-foot plastic films recycling plant in Minnesota, aiming to process up to 45,000 tons of plastic waste annually at full capacity, diverting these valuable materials from landfill;

- Equity investment in Circular Services, the largest privately held recycling and reuse company in North America, including major municipal and commercial contracts;

- Follow-on loan to the Waste Commission of Scott County, a solid waste district in Iowa, to finance the purchase of new optical sorters for the county’s existing materials recovery facility.

Plastics recovery and recycling presents a significant economic opportunity, alongside the environmental upside of millions of tons of plastics diverted from landfills and the natural environment. Increasing plastics recovery, alongside material reduction solutions, scalable reuse systems and innovative new materials, can help meet an addressable market for plastics with potential revenue opportunities of $120 billion in the U.S. and Canada alone. With plastic waste expected to triple by 2060, the need for investments has grown even more urgent.

“The Closed Loop Circular Plastics Fund is a specialty strategy within our Closed Loop Infrastructure Group. SMBC joins our corporate partners, portfolio companies, subject matter experts and experienced Closed Loop Partners team to enhance the ecosystem effect that bolsters our private credit and equity solutions,” said Jennifer Louie, Head of the Closed Loop Infrastructure Group at Closed Loop Partners. “These solutions can help catalyze additional financial participation––accelerating the projects, infrastructure and innovations needed to close the loop on plastics.”

To date, Closed Loop Partners has kept 4.8 million tons of materials in circulation and contributed to the avoidance of 10.1 million tonnes of CO2e. The firm’s vision for a circular economy includes a circular future for plastics––one that reduces the need to extract virgin resources, harnesses design innovation and material science, and champions reuse models and new product delivery models. In the global transition to circularity, all sectors, industries and societies are needed to effect systemic change. Understanding these contributions to global supply chains is necessary, as investors, innovators and cities play key roles in advancing the solutions that can drive forward a global transition to a circular economy.

Interested in applying for financing from the Closed Loop Circular Plastics Fund? Learn more here.

SMBC is an investor in the Closed Loop Circular Plastics Fund. No material conflicts of interest are present as this entity did not receive any compensation for their comments.

About Closed Loop Partners

Closed Loop Partners is at the forefront of building the circular economy. The company is comprised of three key business segments. Closed Loop Capital Management manages venture capital, growth equity, buyout and catalytic private credit investment strategies on behalf of global corporations, financial institutions and family offices. The Center for the Circular Economy unites competitors and partners to tackle complex material challenges and implement systemic change to advance circularity. Circular Services employs innovative technology within reuse, recycling, remanufacturing and re-commerce solutions to improve regional economic and environmental outcomes, and build resilient systems that keep food & organics, textiles, electronics, packaging and more, in circulation and out of landfill or the natural environment. Closed Loop Partners is based in New York City and is a registered B Corp. For more information, please visit www.closedlooppartners.com.

About Sumitomo Mitsui Banking Corporation

SMBC is the commercial banking subsidiary of Sumitomo Mitsui Financial Group, Inc and one of the largest banks globally on the basis of total assets. It provides an extensive range of corporate and consumer banking services in Japan and globally.

About Sumitomo Mitsui Financial Group, Inc.

SMFG is one of the largest financial institutions headquartered in Japan, with an established presence across all consumer and corporate banking businesses. Through the subsidiaries and affiliates, SMFG offers a diverse range of financial services, including commercial banking, leasing, securities, credit card, consumer finance and other services. SMFG’s consolidated total assets were 264 trillion Yen as of December 31, 2022.

Disclaimer:

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Capital Management or any company in which Closed Loop Capital Management or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Closed Loop Capital Management does not utilize its website to provide investment or other advice, and nothing contained herein constitutes a comprehensive or complete statement of the matters discussed or the law relating thereto. Information provided reflects Closed Loop Capital Management’s views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision. Certain information on this Website may contain forward-looking statements, which are subject to risks and uncertainties and speak only as of the date on which they are made. The words “believe”, “expect”, “anticipate”, “optimistic”, “intend”, “aim”, “will” or similar expressions are intended to identify forward-looking statements. Closed Loop Capital Management undertakes no obligation to update publicly or revise any forward-looking statements, whether as a result of new information, future developments or otherwise. Past performance is not indicative of future results; no representation is being made that any investment or transaction will or is likely to achieve profits or losses similar to those achieved in the past, or that significant losses will be avoided.

ecoSPIRITS Closes USD 10 Million Series A Fundraise Led by Closed Loop Partners

May 10, 2023

ecoSPIRITS has raised USD 10 million in an oversubscribed Series A funding round, led by New York-based circular economy investment firm, Closed Loop Partners.

Four leading Asian and global institutional investors have also joined the funding round, including food sector private equity investor, Proterra Asia; Pavilion Capital; Convivialité Ventures, the venture arm of global wine and spirits leader, Pernod Ricard; and ecoSPIRITS’ existing venture capital investor, Wavemaker Partners. The Series A proceeds will be used to strengthen ecoSPIRITS’ leadership position in closed loop packaging technologies for spirits and wine and accelerate its research and development program.

“We are thrilled with the successful close of our Series A round, which not only validates ecoSPIRITS’ impressive progress in building a comprehensive technology platform, but also marks a significant milestone in our journey to global scale. We are equally honoured to welcome leading investors to our journey such as Closed Loop Partners, Proterra Asia, Pavilion Capital and Convivialité Ventures. The future gets brighter when more resources are invested in circular economy innovation.”

Sui Ling Cheah, ecoSPIRITS Executive Board Chair

The new funding will help ecoSPIRITS scale up its hardware, software and Internet-of-Things (IoT) research and development program, expanding its investment in its Intelligent Circular™ roadmap. The funding will also be used to expand operations in key markets worldwide, including the United States, and grow its regional customer and engineering teams in Miami, London, Singapore and Shanghai. At the time of funding, the ecoSPIRITS’ closed loop technology platform is active or launching in 25 countries worldwide, including the majority of the world’s largest economies.

The new investors bring deep expertise in the circular economy, sustainability, the food sector and wine and spirits to the ecoSPIRITS journey. Series A lead investor, Closed Loop Partners, is a leading investment firm dedicated to the transition to the circular economy. A registered B Corp, Closed Loop Partners advances circular solutions across plastics & packaging, food & organics, fashion & beauty and supply chain technology.

Leading Retailers and Local Shops Join Forces in Beyond the Bag’s ‘Bring Your Own Bag’ Pilot, Testing Reuse Solutions Across 150+ Stores in Denver and Tucson

May 01, 2023

Beyond the Bag’s multi-city pilot tests whether collective retailer action can support more customers in bringing their own reusable bags to stores and advance a broader reuse culture

May 1, 2023 – National retailers and local mom-and-pop shops across Denver, CO and Tucson, AZ join forces in the new ‘Bring Your Own Bag’ Pilot, a first-of-its-kind initiative launched by the Consortium to Reinvent the Retail Bag, managed by Closed Loop Partners. Many national brands in the U.S., including Consortium partners CVS Health; Target; DICK’S Sporting Goods; Dollar General; The Kroger Co., through local King Soopers & Fry’s stores; TJX, through local T.J. Maxx, Marshalls and HomeGoods stores; and Ulta Beauty, will simultaneously test bag reduction solutions alongside local mom-and-pop shops to determine whether collective retailer action can drive a broader cultural shift, where bringing your own reusable bag becomes the norm wherever customers shop.

While reusable bags are one of the most adopted reusable products today, research from the Consortium to Reinvent the Retail Bag shows a lack of consistency in use. This pilot aims to reinforce the behavior at scale––supporting customers to remember bags more frequently and to reimagine where they could bring said bags, beyond just the grocery store. Participating retailers will test the same bag reduction strategies found in the Consortium’s Playbook––including signage, marketing and customer prompts about reusable bags––in, near and outside over 150 stores in Denver, Tucson and the surrounding metro areas.

This pilot to reduce single-use plastic waste is taking place at a critical time. Today, it is estimated that 100 billion plastic bags are used annually in the U.S. and fewer than 10% are recycled. Resource limits, supply chain disruption and plastic pollution increase the urgency to move from a take-make-waste economic system and “disposable” culture to a more circular economy where materials are shared and reused. Reducing single-use bags across retailers can make a tremendous difference. Even a 1% bag reduction has a significant impact on our waste footprint––it is equivalent to 1 billion fewer bags used and discarded in the U.S. Empowering customers to bring their own bag plays a key role in single-use bag reduction.

The Bring Your Own Bag Pilot will run from May 1 to July 30, 2023 and is informed by the work of the Consortium to Reinvent the Retail Bag over the past three years, including hundreds of innovations evaluated, multiple solutions tested, and thousands of customers and retail staff surveyed. Based on pilot results, the Consortium will explore scaling these low-cost, easy to implement strategies, catalyzing a national cultural shift around reuse.

If you are interested in learning more about the pilot, or if you are a retailer interested in participating, please visit our website here.

“The most sustainable bag is often the one we already own. Retailers coming together to support customers in bringing their own reusable bag whenever and wherever they shop is a key step to reducing single-use plastic waste,” said Kate Daly, Head of the Center for the Circular Economy at Closed Loop Partners. “This pilot brings to life the Beyond the Bag Consortium’s collaborative, holistic approach to addressing an urgent plastic waste challenge, and we look forward to seeing the impact of this effort at scale.”

“As we expand these reusable bag solutions across CVS Pharmacy locations and learn about consumer behaviors, we continue to see the power in collective retail action,” said Sheryl Burke, SVP of Corporate Social Responsibility and Chief Sustainability Officer at CVS Health. “With everyone’s drive, dedication and collaboration, we will continue making a lasting impact on creating a healthier world today and for future generations.”

“We are hopeful these small local steps can lead to greater progress. If we are successful, this multi-city pilot program will provide a model that retailers can scale in other geographies, realizing near-term environmental impact and cost-savings,” said Denine Torr, Dollar General’s vice president of corporate social responsibility and philanthropy.

“We all need to work together to create healthier, thriving communities across the country. This pilot is another opportunity to engage our customers directly as we work to reduce waste,” said Denise Osterhues, Senior Director, Sustainability and Social Impact from The Kroger Co.

“When it comes to finding alternatives to single-use plastic bags, our team is committed to co-creating accessible solutions that bring everyone to the table,” said Amanda Nusz, senior vice president of corporate responsibility at Target. “We’re thrilled to participate in this pilot alongside our consortium partners to explore new ways of encouraging broader reusable bag use by our guests and communities.”

“We are pleased to participate in Closed Loop Partners’ innovative campaign, and to collaborate with so many other retailers in support of the reduction of the waste created by single-use bags. This campaign aligns with our ongoing corporate responsibility and sustainability efforts, and is anchored by our mission to deliver great value to our customers every day while pursuing initiatives that are environmentally responsible and smart for our business,” said Brenna Zimmer, Vice President, Sustainability at TJX.

“As the nation’s largest beauty retailer, we understand our role and responsibility to do what’s right for our guests and our world. The Ulta Beauty teams in these markets are excited to pilot these bag reduction strategies alongside our retail peers. Working together helps lay the foundation for a future where reuse is the norm and together, we can move the industry forward at scale,” said Kristin Wolf, Ulta Beauty’s Senior Vice President of Enterprise Strategy and Transformation.

“We are thrilled to see this innovative campaign running in our city, which will complement Denver’s existing fee on disposable bags. This approach will build awareness and gives customers more opportunities to build the habit of bringing their own bag,” said Grace Rink, Denver’s Chief Climate Officer. “Together we can reduce waste, prevent litter, and protect our rivers and streams.”

“I am grateful to all of the Tucson retailers who are participating in this pilot campaign,” said Tucson Mayor Regina Romero. “Tucsonans and businesses care deeply about our desert environment. Bringing your own reusable bag when shopping reduces the need for single-use plastic bags, helps us advance our goal of reaching Zero Waste by 2050, and keeps our city clean.”

About the Center for the Circular Economy at Closed Loop Partners

The Center for the Circular Economy at Closed Loop Partners unites competitors to tackle complex material challenges and to implement systemic change that advances the circular economy. Adept at navigating every step in the value chain, Closed Loop Partners brings together designers, manufacturers, recovery systems operators, trade organizations, municipalities, policymakers and NGOs to create scalable innovations that target big system problems.

The Center currently manages three consortia: the NextGen Consortium, to advance solutions that can help address single-use foodservice packaging waste; the Consortium to Reinvent the Retail Bag to identify, test and scale solutions that can help address single-use plastic bag waste; and the Composting Consortium, to pilot industry-wide solutions and build a roadmap for investment in technologies and infrastructure that enable the recovery of compostable food packaging and food scraps. Learn more about the Center’s work here.

About the Consortium to Reinvent the Retail Bag

The Beyond the Bag Initiative, launched by the Consortium to Reinvent the Retail Bag, aims to identify, pilot and implement viable design solutions and models that more sustainably serve the purpose of the current retail bag. Closed Loop Partners’ Center for the Circular Economy launched the initiative with Founding Partners CVS Health, Target and Walmart. The Kroger Co. joined as Grocery Sector Lead Partner, DICK’S Sporting Goods joined as Sports & Outdoors Sector Lead Partner, Dollar General as Value Sector Lead Partner, TJX as Apparel & Home Goods Sector Lead Partner, and Ulta Beauty as Beauty Sector Lead Partner. Ahold Delhaize USA companies, Albertsons Companies, H-E-B, Hy-Vee, Meijer, Wakefern Food Corp., and Walgreens are Supporting Partners, and Conservation International and Ocean Conservancy serve as Environmental Advisory Partners. Learn more about the Consortium here.

Contact: [email protected]