NextGen Consortium Joins the Polypropylene Recycling Coalition to Further Drive the Recovery of Plastic Packaging in the U.S.

December 08, 2020

NextGen Consortium brings its collective strength and insights to the Coalition’s Steering Committee to create stronger markets for recycled polypropylene

Dec 8 — Today, the NextGen Consortium, led by Closed Loop Partners’ Center for the Circular Economy, with Founding Partners Starbucks and McDonald’s, joined the Polypropylene Recycling Coalition as part of the Consortium’s multi-pronged approach to address single-use food packaging waste globally.

Building on the NextGen Consortium’s existing work to advance the design, commercialization and recovery of packaging alternatives — from new materials and recovery strategies to reusable packaging systems that keep materials in use for as long as possible — the Consortium will work with Coalition members to help increase recovery capacity for polypropylene in the United States. Polypropylene is typically found in everyday packaging such as the cup used for iced drinks on-the-go, yogurt cups and coffee pods, among other applications. However, in many markets, polypropylene is not accepted in residential recycling programs and ends up in landfills. According to The Recycling Partnership’s 2020 State of Curbside Recycling report, there may be as much as 1.6 billion pounds of polypropylene available per year from single-family homes that could be recycled into new products.

“Joining the Polypropylene Recycling Coalition was a natural continuation of the work we are doing across different packaging formats, systems and materials to improve the overall recovery of food packaging,” says Kate Daly, Managing Director of the Center for the Circular Economy at Closed Loop Partners. “Alongside packaging design innovation, such as growing tech-enabled reusable packaging models, capturing existing plastic packaging waste is critical for building a more sustainable future. Unrecovered polypropylene in landfills represents an untapped and wasted resource that could be recirculated in the economy, bringing value to numerous stakeholders.”

The Polypropylene Recycling Coalition, established by The Recycling Partnership, unites the industry around improving polypropylene recovery in the U.S. and further developing markets for high-quality recycled polypropylene. Today, the Coalition announced nearly $2 million in grant dollars to upgrade and improve the sorting equipment at recycling facilities and support consumer education programs to advance polypropylene recycling. The Coalition’s investments will widen the total nationwide acceptance of polypropylene in curbside recycling programs to an additional four million people, resulting in the recovery of a larger supply of polypropylene that could be made into new products.

As the NextGen Consortium continues its work across the value chain – with brands, municipalities, material recovery facilities and manufacturers – to advance viable sustainable packaging solutions that can scale throughout the global supply chain and bring value to recovery systems, working with the Polypropylene Coalition will help further our collective impact at scale.

About NextGen Consortium

The NextGen Consortium is a multi-year, global consortium that addresses single-use food packaging waste globally by advancing the design, commercialization, and recovery of food packaging alternatives. The NextGen Consortium is managed by Closed Loop Partners’ Center for the Circular Economy. Starbucks and McDonald’s are the founding partners of the Consortium, The Coca-Cola Company, Yum! Brands, Nestlé, and Wendy’s are supporting partners. The World Wildlife Fund (WWF) is the advisory partner and IDEO is the innovation partner. Learn more at www.nextgenconsortium.com.

About The Recycling Partnership

The Recycling Partnership is a national nonprofit organization that leverages corporate partner funding to transform recycling for good in states, cities, and communities nationwide. As the leading organization in the country that engages the full recycling supply chain from the corporations that manufacture products and packaging to local governments charged with recycling to industry end markets, haulers, material recovery facilities, and converters, The Recycling Partnership positively impacts recycling at every step in the process. Since 2014, the nonprofit change agent diverted 230 million pounds of new recyclables from landfills, saved 465 million gallons of water, avoided more than 250,000 metric tons of greenhouse gases, and drove significant reductions in targeted contamination rates. Learn more at recyclingpartnership.org.

Closed Loop Partners Helps Bridge Funding Gaps for GrowNYC to Continue Composting Services, Recovering New Yorkers’ Valuable Food Scraps

November 18, 2020

November 19, New York — Closed Loop Partners recently provided GrowNYC a grant that will fund operations of three compost collection sites in New York City, bridging gaps in funding left by recent City budget cuts caused by COVID-19. The demand for composting services from New Yorkers has grown significantly in the last few years. However, this year’s unforeseen events have resulted in reductions in publicly-funded organics collection services. Closed Loop Partners has teamed up with GrowNYC to help reopen food scrap drop-off sites that will divert thousands of tons of food waste from landfills, creating valuable, nutrient-rich compost for local communities.

The three food scrap drop-off sites funded by Closed Loop Partners re-opened in October, and are already attracting over 1,000 regular weekly participants and collecting over 7,000 pounds of food scraps each week. Located at GrowNYC’s 79th Street, Abingdon Square and Tribeca Greenmarket farmers markets, these sites offer convenient composting opportunities to Manhattan residents, from downtown to the Upper West Side. Together, these sites collected over 33,000 pounds of food scraps in just one month, with greenhouse gas emission reductions equivalent to conserving 1,435 gallons of gasoline (EPA WARM). As the holidays approach, typically bringing with them substantially higher rates of at-home cooking and associated food scraps, GrowNYC aims to secure additional funding that will allow them to resume operations across all 76 of their original food scrap drop-off sites, helping make composting accessible to all New Yorkers.

“By collecting food scraps from across the city and diverting them from landfills that are costly to taxpayers, we can realize remarkable economic and environmental benefits,” says Ron Gonen, CEO of Closed Loop Partners. “As the city continues to build circularity into their systems, GrowNYC plays a critical role in recapturing valuable materials like food scraps, and we’re proud to partner with them.”

GrowNYC is one of the most established environmental organizations in New York City, engaging over three million New Yorkers every year in environmental programs that improve the city’s quality of life. Supported by recently restored funding from Speaker Corey Johnson and the New York City Council, New York City Sanitation Department (DSNY), Closed Loop Partners and City Council Member Keith Powers, the organization recently reopened 16 of their 76 food scrap drop-off sites across Manhattan, the Bronx, Brooklyn and Queens––showcasing public and private sector collaboration toward a more circular economy. All food scraps collected by GrowNYC are composted locally, in partnership with NYC Compost Project host sites and other community partners, including Big Reuse in Brooklyn and Queens, Earth Matter on Governors Island, the Lower East Side Ecology Center in Manhattan and Queens Botanical Garden.

“We are immensely grateful to Closed Loop Partners for their generous support, allowing us to bring back more food scrap collection sites in NYC, following COVID-related budget cuts earlier this year that brought our compost program to a standstill,” said GrowNYC President and CEO, Marcel Van Ooyen. “At GrowNYC, we work to make living an environmentally conscious lifestyle in the City second nature––something that, particularly right now, would not be possible for many New Yorkers, without help from partners like Closed Loop Partners, as well as the leadership of Speaker Corey Johnson and the City Council.”

In New York City alone, over 30% of the residential waste stream is made up of compostable organic waste, including food scraps, food-soiled paper and yard waste, which too often end up rotting in landfills, emitting greenhouse gases and contributing to climate change. On a macro level, roughly one third of the food produced for human consumption every year––approximately 1.3 billion tons––gets lost or wasted, costing industrialized countries roughly $680 billion in economic value. Thus, it’s critical that we recapture the value of food scraps, bringing value to communities, the planet and business. Especially at this critical moment, as we face the impacts of climate change in addition to the effects of a global pandemic, it is of the utmost importance that we come together to support invaluable services––especially those that build more resilient supply chains and communities.

For more information on GrowNYC’s compost collection sites, the types of materials you can drop off and ways you can support the organization, visit GrowNYC.org.

For information on food scrap drop-off locations citywide, visit nyc.gov/dropfoodscraps.

About Closed Loop Partners

Closed Loop Partners is a New York-based investment firm comprised of venture capital, growth equity, private equity and project finance, as well as an innovation center focused on building the circular economy.

The firm has built an ecosystem that connects entrepreneurs, industry experts, global consumer goods companies, retailers, financial institutions and municipalities. Their investments align capitalism with positive social and environmental impact by reducing waste and greenhouse gas emissions via materials innovation, advanced recycling technologies, supply chain optimization and diversion of materials from disposal.

About GrowNYC

GrowNYC was originally created in 1970 as the Council on the Environment of New York City (CENYC). Born out of the spirit of the first Earth Day, CENYC was initially a policy-based organization, writing comprehensive reports about quality of life issues like air quality, traffic and noise. New York City has changed a lot since then and so has the organization. As the largest and most established environmental organization in NYC, GrowNYC is proud to have played a pivotal role in helping New York City transform over the past five decades. Today, three million New Yorkers each year participate in GrowNYC programs.

Ann Arbor Selected for Major Investment to Reopen Recycling Facility Under Beverage Industry’s Every Bottle Back Initiative

America’s leading beverage companies & Closed Loop Partners invest $800,000 to reopen, rebuild and modernize Ann Arbor’s Materials Recovery Facility joining Michigan leaders & other partners to invest millions collectively on project

ANN ARBOR, Mich. – The American Beverage Association (ABA) announced today, during America Recycles Week, that Recycle Ann Arbor (RAA) has been selected to receive an investment under its Every Bottle Back initiative, a sustained effort to reduce our industry’s use of new plastic and keep our bottles out of the environment. The investment in Ann Arbor will help rebuild and reopen the city’s Materials Recovery Facility (MRF), which has been closed since 2016, preventing recyclable materials from being diverted across state lines for processing. The targeted investment of $800,000, deployed in partnership with Closed Loop Partners, will help create a state-of-the-art materials recovery facility that allows for enhanced sorting of valuable recyclable materials, like the beverage industry’s 100% recyclable polyethylene terephthalate (PET) plastic bottles. The project also leverages capital from additional stakeholders, including $800,000 from the Michigan Department of Environment, Great Lakes, and Energy (EGLE), fostering groundbreaking public-private partnerships to recover valuable local recyclables to keep in manufacturing supply chains.

“Our investment in Ann Arbor will help restore the region’s critical recycling infrastructure, create jobs and showcase effective strategies to build a more circular economy,” said Katherine Lugar, president and chief executive officer (CEO) of the American Beverage Association. “This exciting new project is one in a series of investments the beverage industry is making alongside our environmental partners and community leaders under the Every Bottle Back initiative to boost the collection of our 100% recyclable bottles and cans so they can be remade, as intended.”

Every Bottle Back is an integrated and comprehensive initiative by The Coca-Cola Company, Keurig Dr Pepper and PepsiCo to reduce the industry’s plastic footprint. The investment in Ann Arbor is the fourth of eleven initial projects that the beverage industry has committed funding for under Every Bottle Back to ensure our bottles are collected and remade and do not wind up in beaches or lakes or wasted in landfills.

“Rebuilding Ann Arbor’s Materials Recovery Facility with modernized, state-of-the-art equipment will boost efficiency, increase recycling rates and help keep our valuable fully recyclable PET bottles in-state to help sustain local recycling systems,” said Derek Bajema, president and CEO of Michigan Soft Drink Association. “We are grateful for this opportunity and look forward to working with all those who share our goal of improving our state’s collection system so that it captures more recyclable materials.”

The American Beverage Association is partnering with Closed Loop Partners, the Michigan Department of Environment, Great Lakes, and Energy and Recycle Ann Arbor on the project, which will help equip Ann Arbor’s MRF with upgraded equipment and infrastructure to sort, clean and bale recyclable materials. The investment will allow more valuable recyclable materials to be efficiently captured via curbside, yielding an estimated 284 million new pounds of materials collected over 10 years – including 7 million pounds of PET and 740,000 pounds of aluminum. The investment will provide the City of Ann Arbor with local capacity to more effectively manage their recyclables toward a circular economy that eliminates waste, creates jobs and protects the environment.

“The rebuild of Ann Arbor’s materials recovery facility comes at a critical moment for recycling infrastructure in the United States, amidst a global pandemic that has disrupted supply chains and highlighted the need to keep valuable recycled materials in circulation in local manufacturing supply chains,” said Ron Gonen, CEO of Closed Loop Partners, an investment firm focused on the development of the circular economy. “Together, the American Beverage Association, Closed Loop Partners, the Michigan Department of Environment, Great Lakes, and Energy and Recycle Ann Arbor have pooled key resources to bring this project to fruition, underscoring the importance of working across the public and private sectors to score a victory for future generations.”

“We are pleased to see our Recycling Infrastructure Grant of $800,000 leverage industry financial support for the exciting regional recycling solutions that RAA and others across the state are helping to make happen,” said Liz Browne, acting director of the Materials Management Division at EGLE.

“Local processing of recyclables brings a range of environmental, economic, and social benefits, creating a regional hub that will allow recycling to flourish,” says Bryan Ukena, CEO of Recycle Ann Arbor. “Recycle Ann Arbor’s project to rebuild the materials recovery facility in the area establishes an amazing partnership with the community, local banks, industry funders, government agencies, non-profits, and manufacturers. Recycle Ann Arbor looks forward to bringing its 42 years of experience as a mission-based community recycler to the collaboration.”

Closed Loop Partners Releases Data Visualization Tool That Shows Significant Opportunity to Recapture Valuable Plastic Waste in the U.S. and Canada

November 17, 2020

With only 18% of plastic packaging recycled in the U.S. and Canada, this tool guides investors, brands, entrepreneurs and policymakers to make data-driven decisions and collaborate toward a circular future

Tuesday, November 17 (New York) — Today, Closed Loop Partners’ Center for the Circular Economy released their U.S. and Canada Recycling Infrastructure and Plastic Waste Map, as part of their broader Advancing Circular Systems for Plastics and Packaging Initiative. The comprehensive visual tool brings to light the diversity of plastic waste and the volumes and flows by country and state, highlighting critical opportunities to recapture valuable plastics and re-incorporate them into manufacturing supply chains.

The analysis shows that the U.S. and Canada are sending 11.5 million metric tons of plastic packaging to landfill every year, with the recycling system currently only capturing 18% of packaging. This comes at a time when demand for recycled content is growing rapidly, with over 250 brands and retailers in the U.S. publicly committing to increase their use of recycled content in products and packaging. Yet, the supply of recycled content to meet this fast-growing demand is missing. Closed Loop Partners found that the current supply of recycled plastics meets just 6% of demand for the most common plastics in the U.S. and Canada.

Enhancing the transparency of supply chains and better measuring and understanding the current flow of materials are essential first steps to improve plastics recovery. Closed Loop Partners published the U.S. and Canada Recycling Infrastructure and Plastic Waste Map to identify the magnitude of the plastics waste challenge, the key infrastructure gaps and the opportunity areas. By increasing visibility across the plastics value chain, we can drive collaboration among diverse stakeholders––from policymakers and brands, to plastics manufacturers and materials recovery facilities.

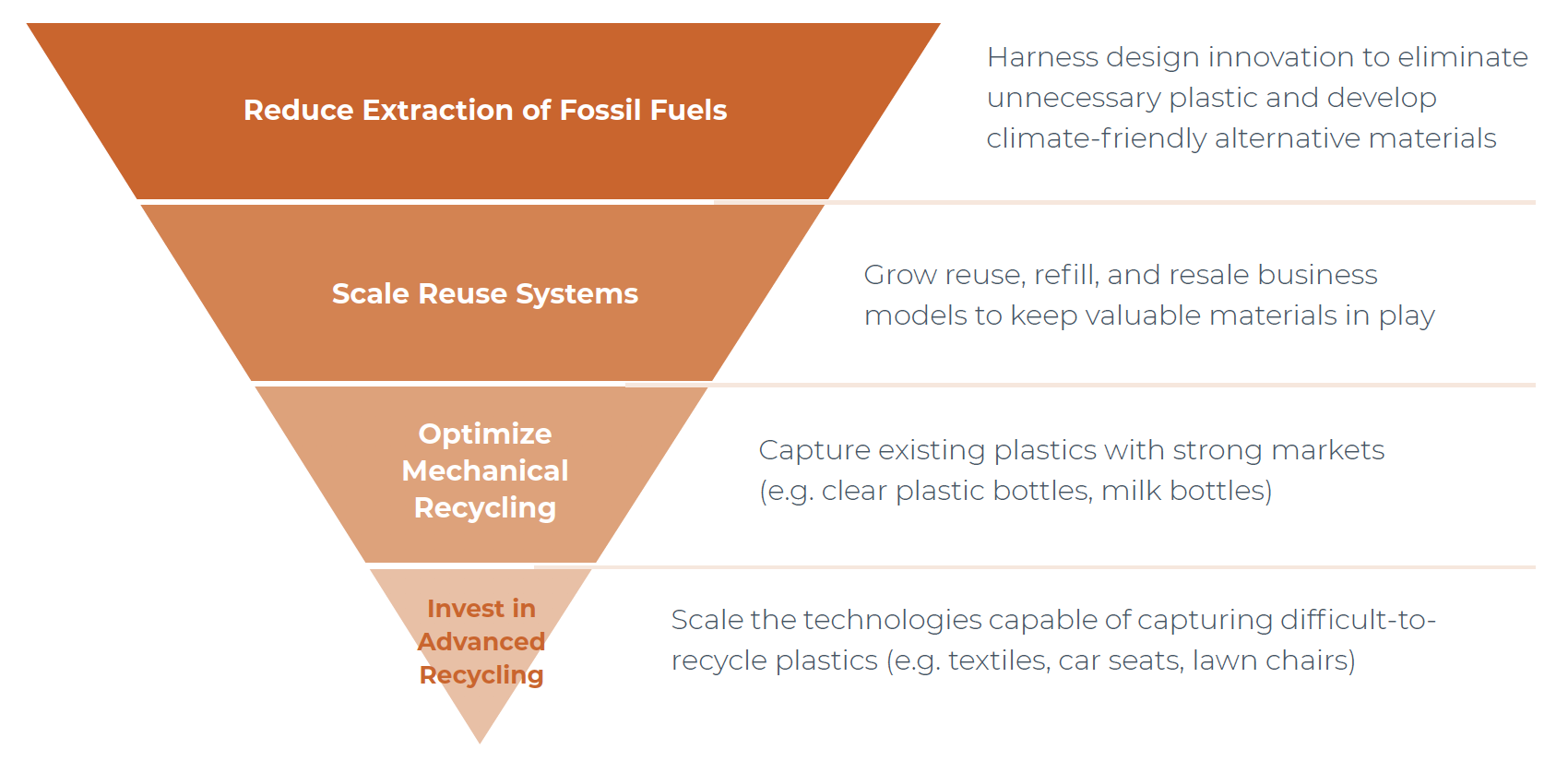

The analysis also highlights the diverse formats, applications and end-of-life markets for plastics, demonstrating the need for multiple solutions to stem plastic waste. Mechanical recycling in the U.S. and Canada recaptures the value of 2,557 million metric tons of plastic packaging after final use per year, primarily from polyethylene terephthalate (PET) plastic bottles kept in circulation. But, mechanical recycling is not an end of life solution for many other forms of plastic waste, like apparel, construction plastics, automotive applications and more, where there may be an opportunity for advanced recycling to fill this gap and solve for these hardest-to-recycle plastic-based products. However, these solutions still cannot serve all materials and markets perfectly or in perpetuity, and we must also deploy and scale reuse and rental systems, among others, to help extend the life of materials and reduce the overall volume of virgin plastic entering the market. Current strategies to address plastic waste are complementary, but taken alone they will be ineffective at producing a circular system for all plastics. Without a multi-pronged approach, plastic waste in all forms, from various industries, will continue to grow.

“To efficiently and effectively tackle all plastic waste, we must first understand the volume and types of plastic flowing through our economy,” says Kate Daly, Managing Director of the Center for the Circular Economy at Closed Loop Partners. “Using plastic packaging as a starting point, this analysis helps investors, brands, entrepreneurs and policymakers understand the diversity of plastic waste in our system and make data-driven decisions. This tool helps galvanize stakeholders to accelerate our collective journey toward a circular economy for plastics through multiple plastic-waste mitigation strategies, and we call upon additional industries to share their data on plastic waste streams to shed light on the additional opportunities.”

Closed Loop Partners embarked on this study to map the volume of plastic packaging and containers specifically, but this is far from the only plastics that must be solved for. The plastics growing in landfill are diverse, including plastics from car parts, healthcare and textiles. The firm is working with organizations across the U.S. and Canada to leverage additional data on other plastic materials and add to this dataset to drive greater transparency and better understanding of all types of plastic waste flowing through current systems. The firm calls upon industry to look beyond packaging and collect data on all plastic waste to create a circular future.

“Foundational to effective action and investment is an informed understanding of where, how much and what quality of plastic waste is being generated in the United States and Canada,” says Anne Johnson, Principal and Vice President of Global Corporate Sustainability for Resource Recycling Systems (RRS). “Packaging waste only scratches the surface of the plastic waste problem. Polyester textiles contribute to 13.4 billion pounds of landfill waste in the U.S., and require both traditional and new advanced recycling platforms to recapture their value after use. This data visualization tool can be built upon to shine a light on the full spectrum of plastic waste in existence today, providing much-needed transparency and collectively advancing a circular economy for plastics.”

“We are excited to see this U.S. and Canada Recycling Infrastructure and Plastic Waste Map from Closed Loop Partners,” says Peylina Chu, Executive Director for the Healthcare Plastics Recycling Council. “As the healthcare industry looks for circular solutions for the millions of tons of clean healthcare plastic, this map helps set a precedent for collaborative efforts along the plastic value chain that can help efficiently identify and leverage synergies between healthcare plastics and other valuable scrap plastic streams as we all add data and share insights on this global waste challenge.”

A more robust understanding of the status quo, strengthened by investments and policies that fill opportunity gaps highlighted by the current waste flow, will increase capacity to process more used material across the country, deliver feedstock for both mechanical and advanced recycling, create demand pull, generate additional jobs, mitigate greenhouse gas emissions and advance the transition to a circular economy.

About Closed Loop Partners

Closed Loop Partners is a New York-based investment firm comprised of venture capital, growth equity, private equity and project finance, as well as an innovation center focused on building the circular economy. The firm has built an ecosystem that connects entrepreneurs, industry experts, global consumer goods companies, retailers, financial institutions and municipalities. Investments align capitalism with positive social and environmental impact by reducing waste and greenhouse gas emissions via materials innovation, advanced recycling technologies, supply chain optimization and landfill diversion. Learn more here.

About Advancing Circular Systems for Plastics and Packaging Initiative

At Closed Loop Partners, we envision a waste-free future for plastics. We launched our Advancing Circular System for Plastics and Packaging Initiative understanding that there is no silver bullet solution to solve complex global waste challenges. Ending plastics waste will require a combination of approaches such as design innovation, reuse and advanced recycling to accelerate the transition to a circular economy for plastics. Our Center for the Circular Economy partnered with Target Corporation, Bank of America, Colgate-Palmolive, 3M, The American Chemistry Council and Sealed Air to produce the U.S. and Canada Recycling Infrastructure and Plastic Waste Map. Our technical partners on this project included Resource Recycling Systems and The Recycling Partnership. Learn more about our investments, collaboration and research here.

Going Beyond Single-Use Packaging to Address All Plastic Waste

November 13, 2020

At Closed Loop Partners, we recognize the need to deploy multiple strategies to build a system that addresses all kinds of plastics. In a world of interdependent, global supply chains, plastic waste is the responsibility of every industry and country around the world. While activism and industry action primarily focuses on single-use plastic packaging, have we been myopic in our framing of the problem?

We are overlooking the equally visible plastics that are just as challenging to recover and reuse: the plastics that make up half the volume of every car; the plastics that make up 20 percent of the 55 million tons of electronic waste sent to landfill annually; the polyester (plastic) that represents 60 percent of all apparel fibers; and 42 percent of all non-fiber plastics which go to packaging. While we’ve developed recovery systems for some plastic packaging, we’ve failed to see the challenge holistically, in ways that address diverse forms of plastics in our system. Meanwhile, they have been steadily mounting in landfills, with limited to no end-of-life solutions.

The reality is that we need to solve for and build systems to prevent, reduce, reuse or recycle all plastic waste, not just packaging. Across industries and sectors, we must deploy all tools available to build a circular system for plastics. These include: harnessing design innovation to eliminate unnecessary plastic and reduce extraction of fossil fuels; scaling reuse systems and rental and resale platforms; investing in mechanical recycling and designing products that align with that system; and investing in advanced recycling technologies that can safely transform hard-to-recycle plastic waste into valuable new products or into building blocks to make new plastic or packaging.

Focusing on a single strategy to the plastic waste challenge compounds risks.

While solutions such as reuse and rental systems are critical to extending the life of a product, they are not necessarily plastic-free systems. Companies such as Rent the Runway allow users to subscribe to a library of clothing, allowing thousands of garments to be shared by 8 million customers. Even so, after dozens or even hundreds of uses, a clothing item likely will need to be retired, but currently no widely available, commercial recycling solutions exist to capture that textile waste. Even the most innovative companies leveraging reuse models for cups, food delivery or personal care packaging include some plastics or other valuable materials in their packaging or services that after many uses will need recycling. These solutions are a small part of supply chains today, but we believe they have a strong opportunity for growth. And as they continue to grow, it is important to think ahead about solutions for the ends-of-life of materials in these systems, to keep them in circulation.

If we consider mechanical recycling, plastics that undergo this process can run through it only about seven times before becoming too degraded, and mechanical technologies cannot process most of the 16.9 million tons of textile waste Americans send to landfill every year.

The current strategies to address plastic waste are complementary, but taken alone they will be ineffective at producing a circular system for plastics. Without a multi-pronged approach, we will continue to see growing stockpiles of plastic waste in all forms, from various industries. We are at a critical moment of consensus. Across industries and sectors, stakeholders agree that we want and need reduction in plastic and better management of the plastics being produced. Enabling these outcomes will require policy shifts, incentives, investment, education and long-term partnerships. And we will need to experiment with and invest in emerging and nascent solutions that can safely solve for difficult material types.

Advanced recycling technologies can contribute one piece to the puzzle, solving for our hardest-to-recycle plastic-based products, such as healthcare-related plastics, multi-layer packaging, apparel and building materials.

Like the plastic waste problem, there is a tendency to oversimplify advanced recycling. It is not a monolith; rather, it is a sector marked by distinct and diverse technology processes that purify or break down plastic to create virgin-quality outputs through a number of biological, thermal and/or catalytic processes including dissolution, glycolysis, pyrolysis and gasification. Closed Loop Partners has categorized these processes into three buckets: purification; decomposition; and conversion. Some technologies, such as pyrolysis, have been around for decades. Others are new and developing; all are improving and not all will be winners. Like anything, it is a growing and competitive landscape and those that are the most cost-effective with the most positive environmental impact likely will advance quickly.

Two very different stories emerged this week around advanced recycling technologies. Purecycle, a purification company, just closed a $250 million bond for its Ohio facility, after successfully proving its technology at scale by processing discarded carpet into clear, high-quality polypropylene. Meanwhile, another advanced recycling technology company, LOOP Industries, was put under the spotlight by a research firm for failing to meet expectations. The stories around Purecycle and LOOP Industries show the importance of deep due diligence and the need for continuous testing and honing of solutions to de-risk them before scaling. We’re continuing to evaluate purification, decomposition and conversion technology processes, their environmental and human health impacts, supply chain economics and policy landscape. The technology processes themselves do not determine whether a company or a process is “circular.” The stakeholders invested in creating circular systems do.

While we’ve developed recovery systems for some plastic packaging, we’ve failed to see the challenge holistically, in ways that address diverse forms of plastics in our system.

Historically, market incentives and policies have not favored circular outcomes from advanced recycling processes. In the United States, manufacturers are not rewarded for using recycled plastic, nor are they penalized for using virgin sources. This has meant that manufacturers have favored the lowest priced commodity on the market, often virgin plastics, and the economics for advanced recycling have bent towards supplying industry with fuel produced from plastics. However, mandates that require recycled content, brand commitments to use post-consumer recycled content for their products and packaging, and landfill bans are becoming more prevalent across diverse markets, increasing the demand for high-quality recycled plastic.

The biggest economic and environmental opportunity in advanced recycling is to build circular supply chains for plastics, meaning plastic-to-plastic loops, which ensure that we keep materials at their highest value within our economy for as long as possible. We can align the advanced recycling market towards circular principles by creating market incentives and supportive policies that recognize these technology processes as recycling when their outputs are directly looped back into plastic supply chains.

Are there unknowns related to these new technologies or processes? Yes. It’s critical that we gain a better collective understanding of the environmental and human health impacts of these recycling processes. We must understand what conditions need to be true to steer the industry towards a circular economy, or risk perpetuating a linear system. Closed Loop Partners is leading a research project with this type of impact assessment as one central objective of our study, alongside an assessment of collections and feedstock processing, and investment guidelines to align this sector to circular principles.

It took the solar industry 40 years to reach 1 million solar systems in the United States, but three years after hitting the 1 million mark in 2016, the U.S. surpassed 2 million systems. In 2010, only 4 percent of new electric capacity was solar, but by 2016, it was 40 percent. Technology development and building an industry around a novel technology takes time, incentives and long-term partnerships to drive investment and scale. Advanced recycling will be no different, and because the sector is newly developing, all stakeholders — brands, retailers, investors, plastic producers and recyclers, NGOs and citizens — have the opportunity and a role to play to ensure a safe and circular system and future.

In 2020, we are continuing our research in the sector to understand the environmental and human health impacts of advanced recycling processes, the policy measures and investable opportunities along the supply chain that can enable a circular future for plastics and a safe and sustainable future. We invite you to learn more about our work on advanced recycling here.

Originally published on GreenBiz.

The Emerging Innovations Transforming How We’ll Bring Goods Home

November 02, 2020

The Consortium to Reinvent the Retail Bag Identifies 58 Shortlisted Solutions Across Reusable Design, Innovative Materials & Enabling Technology––Paving the Way Towards a More Circular Future

The Beyond the Bag Initiative, launched by the Consortium to Reinvent the Retail Bag, aims to identify, pilot and implement viable design solutions and models that more sustainably serve the purpose of the current retail bag. Closed Loop Partners’ Center for the Circular Economy launched the initiative with Founding Partners CVS Health, Target and Walmart. Kroger joined as Grocery Sector Lead Partner, DICK’S Sporting Goods as Sports & Outdoors Sector Lead Partner, and Hy-Vee and Walgreens as Supporting Partners, alongside Conservation International and Ocean Conservancy as Environmental Advisory Partners. OpenIDEO is the Consortium’s Innovation Partner.

What does it take to reinvent the retail bag? And what solutions exist today? These are the questions we asked as we launched the Consortium to Reinvent the Retail Bag in July of this year, bringing some of the nation’s most influential retailers together to solve for the 100 billion single-use plastic bags used annually in the U.S. These bags too often end up polluting our oceans, stuck in our trees or being wasted in landfills, and it’s time that we create a better path forward.

In August, the Consortium opened the Beyond the Bag Challenge, inviting entrepreneurs, designers, suppliers and problem-solvers to submit solutions that replace the current single-use plastic bag. Through the Challenge, the Consortium brings to light future-forward, tech-enabled solutions that can help build a new system that serves the function of the retail bag in a sustainable, affordable and inclusive way––helping transport goods from store to destination in a way that aligns with diverse retail systems and delivers ease and convenience for all. Three months and more than 450 submissions later, it’s clear that an impressive range of innovative solutions exist. Challenge submissions span the globe across 60 different countries, and represent a range of company stages, from early concept startups to established, commercial businesses.

We’re seeing three broad categories of innovation emerge––reusable designs, innovative materials and enabling technology––that highlight key opportunity areas, showing the range of solutions and potentially groundbreaking ways we can change retail.

How might these solutions play out in the world? What might a sustainable retail bag system look like? After evaluating hundreds of potential solutions through the lenses of sustainability, business and technical viability, accessibility, customer behavior and alignment with reuse and recovery infrastructure, the Consortium announced today a shortlist of promising solutions for further exploration [SEE SHORTLIST HERE].

Across the Shortlist, we’re seeing three broad categories of innovation emerge––reusable designs, innovative materials and enabling technology––that highlight key opportunity areas, showing the range of solutions and potentially groundbreaking ways we can change retail. These provide a window into the future, a teaser as to what might be to come. Identifying innovation is the first step, and with the right kind of testing, honing and piloting, we can start implementing new solutions and systems at scale.

As we collectively become smarter about what the market needs, what consumers want in a retail experience and what new technologies might enable futures we can’t yet fully envision, we will seek to better understand how these and other solutions might work together to create an interconnected and informed system that will fundamentally shift the way we are currently shopping and getting goods home.

Reusable Designs Keep Materials in Play for Multiple Uses

Systems-Driven Reusable Packaging Integration by Returnity

There is a growing innovation category for retail packaging centered on reuse. These solutions use durable materials that can serve the purpose of today’s single-use bag, but remain in circulation for multiple uses within a user-friendly system. Many of these solutions also involve transferring ownership back to the producers and manufacturers––shifting away from typical purchasing models and toward renting, leasing and subscription models for packaging. These include bags-as-a-service and shared-bag systems that incentivize companies to see their products or packaging as valuable assets worth investing in. Through the Challenge, we’re seeing how this broad category comes to life in a multitude of formats, especially at the initial customer interaction point––the point of sale. Solutions range from gurney-style carts that fit in the trunk of a car, to compact reusable bag withdrawal and return stations that sit at the checkout counter and continually cleaned, reusable containers that transport products directly to customers’ homes.

The innovations coming to the fore in this category have the potential to address real challenges in the retail experience. Reuse models address short-lived disposable options, extending the use time of the retail bag from today’s 12-minute average to multiple life cycles, keeping valuable materials in play at their best and highest use. However, for their full impact to be realized, it is important to dig deeper into the structures and systems that enable their long-term environmental and economic sustainability, examining reverse logistics and conducting life cycle assessments, among other areas for evaluation.

Innovative Climate-Friendly Materials Can Reduce Impacts on the Planet

#INVISIBLEBAG by Distinctive Action Ltd

Designers today are recognizing that the materials they choose for a product determine how its entire life cycle will play out, from start to end. As a result, there is a growing focus on material science innovation, and a reevaluation of what goes into products for a carbon-free future. The Challenge has brought to light a whole host of new materials that broaden the way we think about the retail bag––aiming for superior performance that better meets the needs of a diverse range of customers, without creating an outsized impact on the environment. These solutions include stretchy fibers derived from nature, water-soluble films, biopolymers processed from agricultural waste, natural materials like algae, seaweed and chitin, and upcycled materials like cotton.

Many of these pioneering solutions draw from rapidly replenishable resources and seek to add material value at end-of-life, whether through composting or recycling systems. They diversify the resources we use to begin with, relieving pressure from just one primary source––especially fossil fuels. At the same time, we need to ensure that these new solutions don’t outpace our existing recovery infrastructure, and are actually recaptured as intended after use.

Enabling Technologies Accelerate the Uptake of Smart, Sustainable Solutions

IoT-enabled Food Delivery & Pickup System by Minnow Technologies

Beyond these innovations are the underlying technological processes and systems that create a scaffolding for other solutions or systems, opening up new exchanges with customers and working towards a bagless future. These might harness Quick Response (QR) codes and/or radio frequency identification (RFID) systems that enable companies and consumers, in effect, to check products or packaging in and out along their lifespan. This increases visibility and digital connectivity, which can drive better logistics and inventory management, informing strategic decision-making and incentivizing customers through “nudges” or reward programs. Innovative and “smart” delivery models, like in store kiosks or mobile applications, can also integrate with other categories––reusable designs or innovative materials––to deliver products.

It is critical that these solutions are able to scale commercially, align with market needs and integrate within existing systems of leading retailers, laying the groundwork for long-term change that cuts across industries.

Now, how do all of these solutions come together? From a birds eye view, the range of solutions is wide, with many of them complementary and potentially overlapping. If we take into account all of the ways we use the retail bag, and all of the different people around the world using retail bags, this diversity of thinking works to our advantage. And we know there are yet more avenues to explore. As we collectively become smarter about what the market needs, what consumers want in a retail experience and what new technologies might enable futures we can’t yet fully envision, we will seek to better understand how these and other solutions might work together to create an interconnected and informed system that will fundamentally shift the way we are currently shopping and getting goods home.

Ultimately, it may not be a single solution, or even a few that solve the problem. With ever increasing ways to purchase goods come ever increasing needs for a myriad of interventions that solve for niche sets of needs within specific customer or delivery segments. In reality, there is no panacea to this complex problem––different geographic, economic and social contexts demand varied approaches that cater to diverse sets of needs. If we are to change the future of retail, these solutions, from reuse models to innovative materials to the enabling technologies, need to communicate with and interrelate within a holistic ecosystem, explore new pathways of collaboration to fill in gaps or amplify one another’s strengths, and work to advance the market together, rather than separately.

This is just the beginning of the journey, both for solutions in the Challenge and for the Consortium collectively. In the lead up to the announcement of Challenge winners in early 2021, we’ll begin working more closely with the Shortlisted innovators, helping refine their solutions, digging deeper to understand their full economic, environmental and social impact, and exploring emerging trends. And as we begin to learn where and how these solutions might apply to today’s challenges as well as tomorrow’s, we will work to advance and implement those which can bridge this innovation gap and have an eye on adaptability and agility, or on those that might enable the successful implementation of another concept or emerging technology––all to ensure we are rolling out new ventures that not only work within the operational parameters of our Partners, but serve both customers and the market at large. Overall, it is critical that these solutions are able to scale commercially, align with market needs and integrate within existing systems of leading retailers, laying the groundwork for long-term change that cuts across industries [SEE SHORTLIST HERE].

As we enter the next phase of this initiative, we are excited to work across the Consortium’s ecosystem of emerging innovators and established retail institutions to drive toward a more inclusive, affordable and sustainable future. Join us on this journey, and stay tuned for our upcoming announcement of the final Beyond the Bag Challenge winners in early 2021.