Climate

Why solving the climate crisis requires a transition to the circular economy

September 20, 2021

This article is part of Closed Loop Partners’ Climate Series, which explores the critical link between transitioning to a circular economy and addressing the climate crisis. By reworking the fundamental flow of materials in our economy, the circular economy offers an economically attractive, socially just and environmentally sustainable way to meet our global climate commitments.

- While the transition to renewable energy is critical to meeting our global climate targets, it will only address about half of our emissions.

- The remaining half are tied to the products and services we consume everyday.

- The circular economy provides the only economically attractive and environmentally sustainable way to transform our production and consumption systems in line with global climate commitments.

- There are already a number of successful circular economy business models that reduce extraction and landfilling costs and cut carbon emissions, paving a pathway forward.

Leaders from almost every nation on earth––197 countries––have signed the Paris Agreement to limit temperature rise to 2 degrees, with an agreement to aim for a 1.5 degree celsius limit. Nearly one-fifth of the world’s 2,000 largest public companies (representing $14 trillion in sales) have committed to net zero emissions.

So why are scientists, activists and leaders across sectors still worried about the climate crisis? Two important reasons come to mind:

- Our current policies push us close to 3 degrees rise in global temperature. Even our pledges only get us to 2.4 degrees.

- It’s not enough to transition to renewable energy. We also need to tackle carbon emissions in the stuff we create, buy, use and dispose of.

Our reliance on “dirty” and non-renewable energy is a significant contributor to our climate crisis, and a rapid and just transition to renewable sources of energy is critical to reducing global emissions. However, that’s only about half of the answer. Research from the Ellen MacArthur Foundation finds that our transition to renewable energy “can only address 55% of emissions. The remaining 45% comes from producing the cars, clothes, food, and other products we use every day.”

What does our linear economy have to do with the climate crisis?

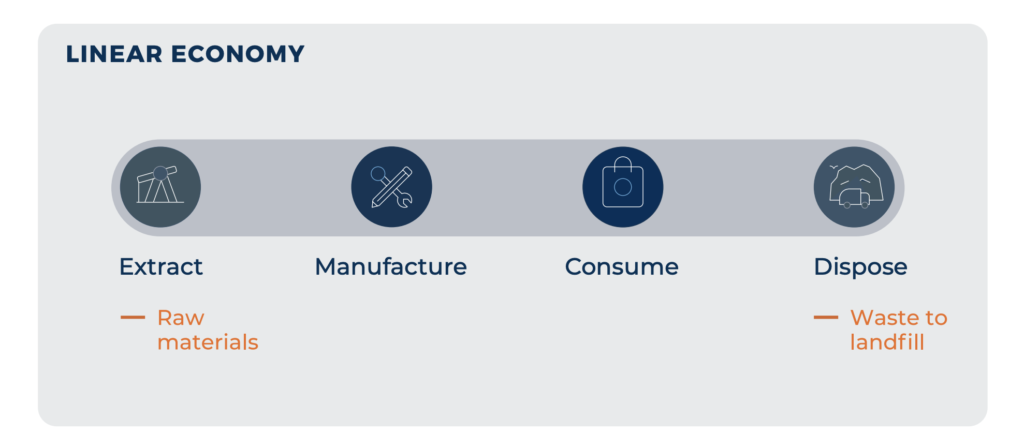

What’s wrong with our current methods of production and consumption? Today’s linear economy is based on a ‘take-make-waste’ model: we take natural resources (extraction) to make products (production/manufacturing) and when we’re done using them (consumption), we dispose of them (waste/landfilling).

LINEAR ECONOMY

At the take/extraction phase, this is an issue because we don’t have access to unlimited natural resources. Today, we are using about 1.6 earths; meaning we’re using about 50% more of the earth’s resources than it can regenerate every year. By 2050, with an increased global population and resulting rise in consumption, that “overshoot” could get to 3-4 earths, which is clearly unsustainable. From a climate crisis perspective, extraction––a key part of our linear economy––is responsible for “53% of the world’s carbon emissions” and “more than 80% of biodiversity loss,” according to a study done by UN Environment.

At the other end of the linear value chain, waste/landfilling is also directly contributing to greenhouse gas (GHG) emissions and our climate crisis. Why are landfills especially insidious? In addition to taking up otherwise productive land, this explanation from Waste Dive is especially helpful: “when trash is packed into a pile, the oxygen-free environment supports bacteria that thrive in those conditions. As the microbes degrade the waste, they release carbon dioxide and methane. The latter is…84 times more potent of a global warming agent than carbon dioxide in the first 20 years of its release.”

And while we know that methane released in landfills is particularly harmful to the environment, we are still learning about the extent of their impact. In the United States, a recent multi-year aerial study of “super-emitter landfills accounted for 43% of the measured emissions of the potent greenhouse gas methane––outpacing the fossil-fuel and agricultural sectors” while “the ten biggest methane-emitting landfills pumped out the gas at rates averaging 2.27 times the federal estimates.”

How does a circular economy help address the climate crisis?

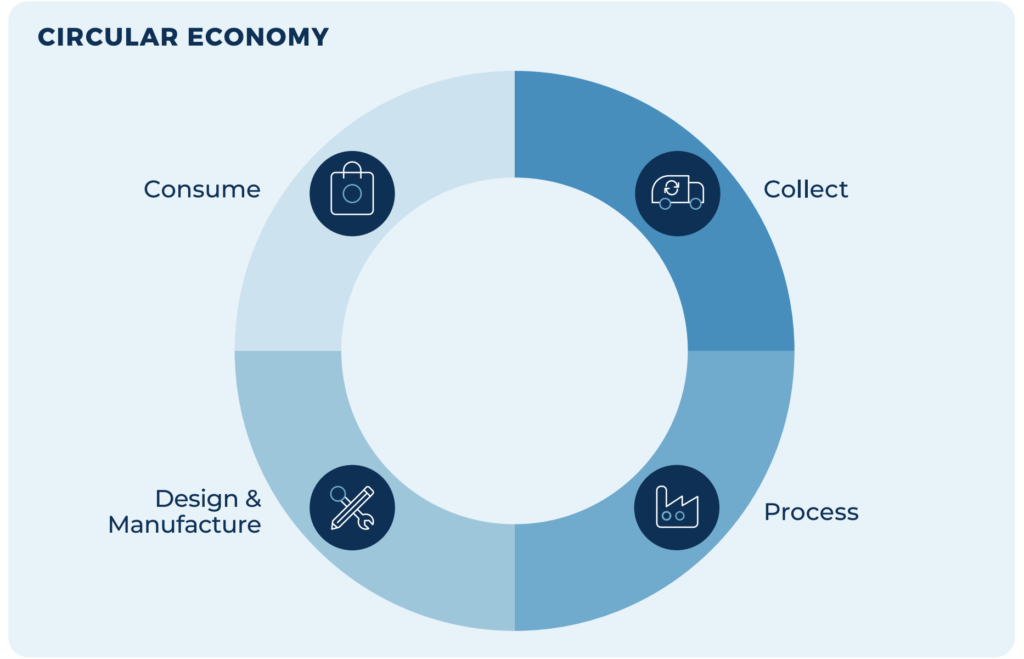

Transitioning from a linear to a circular economy is critical to addressing the 45% of emissions associated with our current models of production and consumption. Unlike the linear “take-make-waste” model described above, a circular economy eliminates the concept of waste altogether, moving us into a more closed loop system where materials and products are kept in use as long as possible. In doing so, the circular economy tackles some of our greatest social and environmental challenges while unlocking $4.5 trillion in economic value by 2030.

CIRCULAR ECONOMY

As you’ll notice in the diagram above, the two emissions-heavy ends of the linear value chain––extraction and landfilling––are eliminated, as they are not valuable in a circular economy. How do you eliminate such prevalent parts of today’s value chain?

Let’s start with extraction of natural resources. Since the beginning of the first industrial revolution, we’ve had a nearly 1:1 relationship between economic growth and the use of natural resources. According to UNEP, global extraction of natural resources has more than tripled since the 1970’s and by 2060, “global material use could double to 190 billion tonnes (from 92 billion), while [GHG] emissions could increase by 43%.” While improving resource efficiency is helpful, our current and projected extraction rates (and associated GHG emissions) are largely influenced by increased consumption and our reliance on single-use products and packaging made from finite natural resources, like fossil fuels.

In a circular economy, the use of toxic, single-use or non-renewable inputs are reduced, and ideally eliminated. Circular design and sourcing instead favor inputs that do not rely on extraction of natural resources, valuing materials that are renewable, regenerative, reusable and recyclable.

But we can’t just focus on better and more sustainable inputs to our products. Valuable materials, including those that are naturally sustainable like food, can still end up as “waste” in the environment and in landfills, resulting in carbon dioxide and methane emissions. Today, the world produces over 2 billion tons of solid waste, and that’s expected to grow to 3.4 billion tons by 2050. By volume, global waste includes 44% food and organics, 17% paper and 12% plastic––all materials that could be valuable in a circular economy.

By keeping products and materials in play as long as possible––by extending the life of products and reprocessing materials at end of use––the circular economy eliminates the need for both extraction of natural resources and landfilling or incineration of goods. Circular systems prioritize local, “short” material loops in which communities benefit from valuable materials re-entering local manufacturing supply chains, creating new jobs, spurring innovative end markets and fostering a healthier environment. By advancing local solutions, the circular economy provides more communities with the tools needed for resilience against a globally changing climate, and, of course, reduces or eliminates the significant GHG emissions and economic costs associated with the linear economy.

How can we accelerate our climate commitments through the circular economy?

Investments, innovations and regulations that encourage a circular economy see materials as valuable commodities rather than products of a single-use, extractive-intensive and wasteful society. Let’s explore a few examples across the linear to circular value chain.

Keeping materials in play. Over 500 companies have signed the Global Commitment for a New Plastics Economy, including the world’s largest consumer goods companies. At the same time, less than 9% of plastics are recycled globally. Investments in the collection, sortation and reprocessing of materials – including plastics, glass, paper, aluminum, etc. – are critical to keeping materials in play and reducing what is sent to landfills. For example, Eureka Recycling, a locally operated nonprofit Material Recovery Facility (MRF) in Minneapolis, was able to increase its recovery of recyclables by 13% by upgrading equipment to improve sortation capacity. This resulted in 1 million pounds more of PET plastic recovered annually, which is the same as almost 20 million plastic water bottles. If lined up, this would be enough water bottles to connect New York to San Francisco. By keeping these valuable commodities out of landfills, we reduce the need for extraction to produce virgin plastics.

Some materials can be more difficult to recycle or reprocess at the end of use. Cotton, a highly resource-intensive crop, is an example of a popular material that is not often reprocessed or recycled, especially post-consumer use. Circular startup Evrnu has developed a novel technology to transform challenging textiles like 100% post-consumer cotton into new, like-virgin materials. Similar to the example above, this kind of solution eliminates the need, costs and emissions impact of extraction (production of virgin cotton) and landfilling (used cotton to waste).

Finally, some materials like organics––food scraps, yard and agricultural waste, human waste, etc.––are not a great candidate for reuse or reprocessing. In a circular economy, we can turn organics into valuable sources of energy and fertilizer. Israel-based HomeBiogas uses anaerobic digestion to convert organic materials into fuel for cooking or hot water. In addition to reducing the costs and emissions associated with sending food waste to landfills, this circular solution creates valuable products that reduce the need for extraction (e.g. cooking fuel) and improves soil health (e.g. natural fertilizer).

Switching to more sustainable materials. Rather than focusing on the end-of-life of products and keeping materials in play via models like recycling, some circular solutions are focused on alternative materials that are less extractive and more sustainable from the outset, while still maintaining the same performance as traditional materials. Algaeing, for example, is using biodegradable and energy-efficient algae as an alternative material for fashion and textiles. In addition to reducing the use of water and eliminating the need for toxic chemicals and pesticides commonly used in textiles, their algae alternative reduces the costs and emissions associated with both extraction/production and landfilling of materials like cotton and polyester.

Reducing the need for materials. Half of all packaging is designed to be used only once––also known as “single-use packaging”––and then thrown away. Most often, that packaging is not the primary source of value of a product, as we’re usually buying what’s inside. Think of a bottle of shampoo or detergent – a big part of the item cost is for the packaging, which doesn’t really offer value to the consumer. Started in Chile to address economic and environmental issues associated with the packaging of household staples like cleaning supplies, Algramo’s smart vending machines dispense products “by the gram” (hence the name!) into reusable containers. This reduces both the environmental impact and cost associated with single-use packaging, and provides a much more convenient way for people to buy common goods.

Extending the life of our stuff. Outside of single-use packaging, more and more “durable” items are prematurely thrown away, despite having multiple uses or “lives” left in them. This is exacerbated by the rise in on-demand purchasing via eCommerce and “fast consumption” lifestyles. Several startups are looking to reverse this trend, by finding both economic and environmental value in circular business models that extend product use to multiple consumers. For Days, for example, has developed a circular business model for typically fast fashion items like t-shirts and sweatshirts. They incentivize customers to return clothing at end of use through discount pricing and reverse logistics, keeping apparel out of landfills.

We can even extend the life of organic products like food. As mentioned above, food waste is a significant part of landfills and a dangerous contributor to both methane production and food insecurity. Start-up Mori has developed a tasteless and sustainable coating, inspired by the Mori silkworm, to extend the life of perishables like fruit, vegetables and seafood. In addition to reducing the amount of food waste that ends up in landfills (contributing to climate change via methane emissions), Mori’s solution also reduces the need for food packaging, further reducing emissions and costs associated with the extraction and landfilling of single-use packaging.

So, what’s next?

Circular economy business models offer a clear pathway toward achieving our collective climate goals, tackling the greenhouse gas emissions tied to the extraction, processing, manufacturing, and landfilling of goods. Already, there is a burgeoning ecosystem of innovators that are breaking away from the take-make-waste linear business model in favor of a circular economy, in doing so benefitting people, the planet, and business.

Next in Closed Loop Partners’ climate series, we’re going to explore how we can enact change more quickly to accelerate the transition to circularity. What are the levers we need to collectively pull? Who are the key stakeholders involved? What are we asking of governments and corporations?

$4.2M in Grants Awarded to Improve Polypropylene Curbside Recycling for Nearly 15 Million Americans

August 23, 2021

In less than one year, The Recycling Partnership’s Polypropylene Recycling Coalition awarded grants to 13 recycling facilities to increase recycling access by nearly 6%.

FALLS CHURCH, Va. (Aug.24, 2021) – The Recycling Partnership today announced a third round of grant funding through its Polypropylene Recycling Coalition, distributing an additional $1.8 million in catalytic grants to advance polypropylene recycling and reduce plastic waste in the U.S. Launched just one year ago, the Coalition has awarded grants that will improve curbside polypropylene recycling access for nearly 6% of all U.S. households. These grants will positively impact nearly 15 million Americans through grants to 13 facilities totaling $4.2 million to date. The Coalition is a cross-industry effort supported by steering committee members Keurig Dr Pepper, Braskem, NextGen Consortium, and the Walmart Foundation, along with other members of the polypropylene value chain.

Polypropylene, sometimes referred to as PP or No. 5 plastic, is used in an array of food and non-food packaging and is in strong demand as a recycled material. Through its third round of grant funding, the Coalition will provide six grants to Materials Recovery Facilities (MRFs) across the U.S. to boost sortation of polypropylene and support targeted consumer education efforts. To date, the Coalition has awarded grants across the U.S. to increase the recovery of polypropylene by an estimated 13 million pounds annually to be made into new products, such as consumer packaging and automotive parts, rather than being sent to landfills, incineration, and into the environment. The widespread interest and commitment from MRFs across the U.S. to increase the collection and sortation of recyclable polypropylene clearly demonstrates the market strength for this material nationwide and has catalyzed more than $10 million in additional private investments in polypropylene sortation within U.S. MRFs.

“In just one year, the Polypropylene Recycling Coalition has led the way to rapidly drive significant, measurable change to improve and increase the capture of polypropylene in U.S. curbside recycling,” said Sarah Dearman, Vice President of Circular Ventures, The Recycling Partnership. “The Recycling Partnership is proud to lead the Polypropylene Recycling Coalition and its meaningful work that is inspiring industry investment, supporting jobs, preserving natural resources, and activating the transition to a circular economy in the United States.”

The Coalition makes grants to MRF candidates that face challenges in their ability to effectively sort and recycle polypropylene. According to recent studies of U.S. recycling access, just under 60% of Americans have access to recycling polypropylene. With the Coalition’s strategic grants, it is estimated curbside acceptance of polypropylene will increase by nearly 6% once all equipment is installed by early 2022. This will result in more No. 5 plastic being sent to established end markets and encouraging the shift to a circular economy. Consumers in these areas will also be educated as to what is and isn’t accepted in their curbside recycling.

Domestic reclaimers and re-processors further along the PP value chain acknowledge the supply signals sent by the Coalition’s MRF grants. In response, many made investments to prepare for processing the increased supply of this material for returning it to domestic end markets. Coalition members alone with reclamation and reprocessing facilities made more than $32 million in investments over the past year to increase polypropylene reclamation capacity by nearly 800 million pounds within their North American facilities. Additional reclamation and reprocessing investments are planned or underway for 2022, as multimillion dollar infrastructure investments are still needed.

The geographic reach of the first three rounds of Coalition MRF grantees includes the Northeast, Southeast, Upper Midwest, South Central, and West Coast regions, including California. The Coalition received a strong response to each of the three prior requests for proposals and continues to accept grant applications to further its efforts to advance polypropylene curbside recycling. The next grant proposal request is due Sept. 30, 2021. MRFs interested in sorting and recycling polypropylene are encouraged to apply.

The six newest grantees are:

- Green Waste, San Jose, Calif.

- Murphy Road, Berlin, Conn.

- Palm Beach County, Fla.

- Pellitteri, Madison, Wis.

- Sonoco-Raleigh, Raleigh, N.C.

- Sonoco-Onslow, Jacksonville, N.C.

The mission-driven work of the Coalition is supported by contributions from organizations representing all segments of the polypropylene value chain, including the Coalition’s newest members, Advanced Drainage Systems, Berry Global, Plastic Ingenuity, and PureCycle. In addition to the aforementioned steering committee members, other members of the Coalition include Campbell Soup Company, EFS-plastics, The Kroger Co. Zero Hunger | Zero Waste Foundation, KW Plastics, LyondellBasell, Merlin Plastics, Milliken & Company, Nestlé, PolyQuest, Procter & Gamble, Sabert Corporation, St. Joseph Plastics, and Winpak. The Coalition is advised by industry leaders, including Association of Plastic Recyclers, former EPA Administrator Carol Browner, Closed Loop Partners, Sidewalk Infrastructure Partners, Sustainable Packaging Coalition, and World Wildlife Fund.

The Coalition is part of The Recycling Partnership’s Pathway to Circularity, an initiative creating scalable solutions to packaging and system challenges to accelerate the shift to a circular economy that uses fewer finite resources.

To learn more about the Polypropylene Recycling Coalition, its members, and how to get involved in supporting its goals, visit recyclingpartnership.org/polypropylene-coalition. For MRFs interested in applying for a grant, the application is available on our website.

About The Recycling Partnership

The Recycling Partnership is the action agent transforming the U.S. residential recycling system for good. Our team operates at every level of the recycling value chain and works on the ground with thousands of communities to transform underperforming recycling programs and tackle circular economy challenges. As the leading organization in the country that engages the full recycling supply chain, from working with companies to make their packaging more circular and help them meet climate and sustainability goals, to working with government to develop policy solutions to address the systemic needs of the U.S. recycling system, The Recycling Partnership positively impacts recycling at every step in the process. Since 2014, the nonprofit change agent diverted 375 million pounds of new recyclables from landfills, saved 968 million gallons of water, avoided more than 420,000 metric tons of greenhouse gases, and drove significant reductions in targeted contamination rates. Learn more at recyclingpartnership.org

Upstream and Closed Loop Partners Announce Nominees of Inaugural National Reuse Awards

August 17, 2021

The Reusies: Virtual awards show for Reuse Movement in the U.S. celebrates heroes of a world without waste on September 30 ─

NEW YORK, Aug. 17, 2021 /PRNewswire/ — Upstream, a non-profit sparking innovative solutions to plastic pollution, today announced the nominees of the first-ever virtual National Reuse Awards (aka The Reusies), which will take place Thursday, September 30. Presented in partnership with circular economy-focused investment firm and innovation center, Closed Loop Partners, the awards show will be hosted by TV personality and science communicator Danni Washington and celebrate the heroes of reuse.

Tickets to attend the event and sponsorship honoring Most Innovative Reuse Company, Activist of the Year, Fan Favorite Reuse Company, and Most Impactful Community Leadership are available as of today. The final winners will be announced during the show.

“The Reusies is a celebration of pioneers and innovators in the growing reuse economy,” said Matt Prindiville, CEO at Upstream. “The individuals and organizations we’re recognizing are launching innovative ideas to protect the planet. They’re charting a future to get what we want and need without all the waste.”

The nominees for Most Innovative Reuse Company are: Algramo, Rheaply, and TURN.

The nominees for the remaining three categories are:

- Fan Favorite Reuse Company: Blueland, Just Salad, Plaine Products, Saalt, and Stojo

- Most Impactful Community Leadership: ReusableLA and Zero Waste Humboldt

- Activist of the Year: Craig W. Cadwallader – Policy Coordinator, Surfrider Foundation (South Bay Chapter); Crystal Dreisbach– Founder, Green to Go and Executive Director, Don’t Waste Durham; Anukampa Freedom Gupta-Fonner – Chief Imagineer, Design By Freedom

Award winners (except Fan Favorite Reuse Company) will be selected by a combined panel of judges and public voting. Judges include:

- Ashima Sukhdev, Programs Lead – North America, Ellen MacArthur Foundation

- Benjamin Von Wong, visual artist, activist, influencer

- Christian Kaufholz, Head of Affiliate Programs & Knowledge Development, Global Plastic Action Partnership, World Economic Forum

- Danni Washington, TV personality, science communicator, ocean advocate

- Elizabeth Segran, senior staff writer, Fast Company

- Erin Simon, Head of Plastic Waste & Business, World Wildlife Fund

- Lauren Singer, founder and CEO, @PlasticFreeShop and @trashfortossers

- William McDonough, Chief Executive, McDonough Innovation and Co-author, Cradle to Cradle: Remaking The Way We Make Things

Added Kate Daly, managing director at Closed Loop Partners, on why they chose to be a presenting partner: “Reuse is vital in addressing the global waste challenge. We’re joining forces with Upstream to bring attention to the incredible ecosystem of innovators working toward a circular future. This builds on our existing work, as we research, test and invest in solutions that keep valuable materials in circulation longer.”

The event will be emceed by Danni Washington and streamed online on Thursday, September 30 at 4:00PM PT / 7:00PM ET and include performances by singer Kori Withers, video montages, award presentations, and a panel discussion on why reuse wins for the environment and economy through innovation and entrepreneurship. There will also be a live VIP session immediately after the show with speed networking in online breakout rooms.

Tickets are now available at www.TheReusies.org at an early-bird price of $10 for general admission (one screen) through August 31 (after that, general admission ticket cost will increase to $25). VIP Tables (which include 10 screens, access to the VIP after show and other perks) are available at $2,500. Category-exclusive sponsorship and brand integrations are also available. For more information, email [email protected] or visit the event website. For press inquiries contact Jen Maguire, [email protected]; social: #TheReusies @Upstream_org @LoopFund.

SOURCE Upstream

Related Links

Closed Loop Partners and Every Bottle Back Invest $5 Million in Evergreen to Expand Bottle-to-Bottle Plastics Recycling

August 12, 2021

The collective investment from America’s leading beverage companies and Closed Loop Partners will fund a major expansion in Evergreen’s Clyde, Ohio materials recovery and manufacturing facility

CLYDE, Ohio – The American Beverage Association and the Ohio Beverage Association, in partnership with Closed Loop Partners, announced today that Evergreen, a plastics reclaimer and rPET manufacturing facility based in Clyde, Ohio, will be the next recipient of a significant investment under the beverage industry’s Every Bottle Back initiative.

The $5 million investment – half from the American Beverage Association in partnership with Closed Loop Partners and the other half from Closed Loop Partners’ Infrastructure Fund – is part of Evergreen’s $22 million expansion project that will grow operations and double production capacity by 2022. This investment helps Evergreen evolve its business model, expanding its services to process recycled PET plastic into food-grade recycled rPET pellets used to manufacture new bottles, while creating a strong local market for recycled plastics.

The expansion project is estimated to yield at least 58 million pounds of food-grade PET in its first year alone, and cumulatively at least 600 million pounds of rPET food-grade pellets over a 10-year period.

“We are excited to support Evergreen’s expansion, which will help Ohio’s beverage companies close the loop on its 100% recyclable beverage containers,” said Kimberly McConville, executive director of the Ohio Beverage Association. “This is the second Every Bottle Back investment in Ohio, building on our industry’s commitment to strengthen recycling infrastructure, increase the collection of our plastic bottles and work towards using more recycled content.”

Spearheaded by the American Beverage Association, Every Bottle Back is a groundbreaking initiative by The Coca-Cola Company, Keurig Dr Pepper and PepsiCo to reduce the beverage industry’s plastic footprint by getting back more of the industry’s recyclable plastic bottles to be remade into new bottles, as intended. This latest investment will help finance a new building at Evergreen’s Clyde plant, where recycled polyethylene terephthalate (rPET) will be processed and ground into pellets to be used for making new plastic bottles and other consumer goods.

“Through our partnership with Evergreen and Closed Loop Partners, this project – along with several others throughout the region and country – will help capture and process more of our valuable, 100% recyclable plastic bottles so they can be remade into new bottles,” said Katherine Lugar, president and CEO of the American Beverage Association. “This project is another example of the power of private-public partnerships created through Every Bottle Back to build a circular economy for plastic and keep it out of the environment.”

“To build a truly circular economy and meet the demand for food-grade recycled content, bottle-to-bottle recycling is critical,” says Ron Gonen, Founder & CEO of Closed Loop Partners. “This investment in Evergreen helps strengthen the market for recycled plastics and inspire other local markets and states to participate in building a waste-free future. Together, Evergreen and the American Beverage Association have pooled key resources to make this project a priority, underscoring the importance of working across the public and private sectors to reduce the use of new plastic and protect the planet for future generations.”

“Evergreen is pleased to partner with the Ohio Beverage Association and Closed Loop Partners to expand our Clyde recycling and manufacturing facility and accommodate the heightened demand for rPET,” said Omar Abuaita, CEO of Greenbridge, the parent company of Evergreen. “This expansion project will double our manufacturing capacity of food-grade rPET and create new jobs while building on our company’s commitment to recycling, sustainability and closed loop solutions.”

This investment to expand Evergreen is the 10th of 13 initial projects that the beverage industry has committed to fund under Every Bottle Back, including recent investments in: Central Ohio; Marquette, Mich.; Ann Arbor, Mich.; and Kenosha, Wis. These investments total $10.6 million in committed funding and will yield an estimated 647 million more pounds of PET over 10 years.

###

About the American Beverage Associations’ Every Bottle Back initiative

The Every Bottle Back initiative is an integrated and comprehensive initiative by The Coca-Cola Company, Keurig Dr Pepper and PepsiCo, alongside sustainability leaders Closed Loop Partners, The Recycling Partnership and World Wildlife Fund, designed to improve plastics circularity. These efforts support individual sustainability commitments undertaken by The Coca-Cola Company, Keurig Dr Pepper and PepsiCo.

Learn more about Every Bottle Back at www.EveryBottleBack.org.

About Evergreen

Evergreen, a division of Greenbridge, was established in 1998 to provide a sustainable, reliable supply of polyester resin for Greenbridge’s portfolio of PET strapping. Today Evergreen is among the nation’s largest plastic (PET) recyclers, collecting and processing more than two billion post-consumer PET bottles and currently produces a combined total of more than 80 million pounds of food-grade rPET annually at its locations in Clyde, Ohio, and Riverside, California. Evergreen is transforming plastic recycling with advanced robotics and state-of-the-art manufacturing lines. We are the preferred supplier of food grade rPET pellets and flake to many top global brands, helping customers increase recycled content in their plastic packaging, achieve sustainability goals and more fully participate in Environmental, Social and Governance programs. Learn More at www.EvergreenTogether.com.

About Closed Loop Partners

Closed Loop Partners is a New York-based investment firm comprised of venture capital, growth equity, private equity, project-based finance and an innovation center focused on building the circular economy. The firm has built an ecosystem that connects entrepreneurs, industry experts, global consumer goods companies, retailers, financial institutions, and municipalities, bridging gaps and fostering synergies to scale the circular economy. Learn more at www.closedlooppartners.com

To schedule an interview, please contact American Beverage’s Press Office at [email protected].

Disclaimer:

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Capital Management or any company in which Closed Loop Capital Management or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Closed Loop Capital Management does not utilize its website to provide investment or other advice, and nothing contained herein constitutes a comprehensive or complete statement of the matters discussed or the law relating thereto. Information provided reflects Closed Loop Capital Management’s views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision. Certain information on this Website may contain forward-looking statements, which are subject to risks and uncertainties and speak only as of the date on which they are made. The words “believe”, “expect”, “anticipate”, “optimistic”, “intend”, “aim”, “will” or similar expressions are intended to identify forward-looking statements. Closed Loop Capital Management undertakes no obligation to update publicly or revise any forward-looking statements, whether as a result of new information, future developments or otherwise. Past performance is not indicative of future results; no representation is being made that any investment or transaction will or is likely to achieve profits or losses similar to those achieved in the past, or that significant losses will be avoided.

Sealed Air Invests $5 Million in Closed Loop Partners’ Circular Plastics Fund to Scale Plastics Recycling

August 10, 2021

The catalytic Fund aims to fill capital gaps and attract additional investment toward circular solutions that combat plastic waste in the United States and Canada

Aug 10, 2021 – New York – Sealed Air (NYSE: SEE), a leading packaging manufacturer, announced a $5 million investment in the Closed Loop Circular Plastics Fund to advance the recovery and recycling of plastics in the U.S. and Canada. This announcement follows an initial investment totaling $25 million from Dow, LyondellBasell and NOVA Chemicals, followed by a $5 million commitment by SK Global Chemical into the Fund.

SEE’s investment brings the Fund closer to its goal of deploying $100 million to advance scalable recycling technologies, equipment upgrades and infrastructure solutions. The Fund’s catalytic strategy fills investment gaps to spur recycling markets, attracting additional corporate investors and financial institutions and accelerating capital inflows beyond the Fund’s own commitments. At scale, the Fund’s investments aim to recycle more than 500 million pounds of plastics over the Fund’s lifespan.

“SEE’s investment in the Closed Loop Circular Plastics Fund demonstrates their commitment to be a part of the solution to plastic waste, marking a critical step in building a waste-free future for the plastics and packaging industry. Their scale and deep expertise in the space allow us to extend our reach even further and encourage other companies to invest more capital to scale critical sustainable solutions,” says Ron Gonen, Founder & CEO of Closed Loop Partners. “Current supplies of recycled plastics meet only 6% of demand for the most commonly used plastics in the U.S. and Canada. By investing in recycling infrastructure and innovation, we can ensure plastics are incorporated back into manufacturing supply chains after use, instead of going to landfills or the natural environment.”

As a global packaging, technology and solutions company with multiple brands and extensive reach, SEE’s investment in the Closed Loop Circular Plastics Fund demonstrates leadership in shaping a future that is more sustainable for the plastics and packaging industry. This investment is part of Sealed Air’s SEE Ventures initiative that invests in disruptive technologies and new business models. SEE’s investment in this fund builds on the company’s current sustainability and plastics pledge to design or advance packaging solutions to be 100% recyclable or reusable by 2025.

“We are driving the packaging industry to a future that is more sustainable, where plastics are recovered and reused in a scalable way,” said Ted Doheny, President & CEO of SEE. “Together we can make a bigger impact, and we are proud to join other companies to invest in this Fund and help advance recycling efforts and improve the circular economy for packaging, especially flexible plastics.”

The Closed Loop Circular Plastics Fund, managed by Closed Loop Partners, will invest in three strategic areas to increase the amount of recycled polyethylene (PE) and polypropylene (PP) available to meet the growing demand for high-quality, recycled content in products and packaging:

- Access – Increasing the collection of targeted (PE) and (PP) plastics by advancing current and next-generation material collection systems, including transportation, logistics and recycling sortation technologies and infrastructure.

- Optimization – Upgrading recycling systems to more efficiently aggregate, classify and sort the targeted plastics to increase the total amount of high-quality plastics, including food-grade and medical-grade plastics, sent for remanufacturing.

- Manufacturing – Investing in facilities and equipment that manufacture finished products, packaging or related goods using recycled content, including recycled PE and PP.

Since its founding in 2014, Closed Loop Partners’ existing portfolio of more than 50 investments has diverted more than 4,600 million pounds of material from landfills and back into manufacturing supply chains. Building on this, the Closed Loop Circular Plastics Fund will deploy a flexible mix of debt and equity financing, and will also aim to stimulate mainstream co-investments, including those from financial institutions, into circular solutions for plastics to further accelerate impact at scale.

About the Closed Loop Circular Plastics Fund at Closed Loop Partners

The Closed Loop Circular Plastics Fund provides catalytic financing to build circular economy infrastructure and improve the recovery of polypropylene and polyethylene plastic in the U.S. & Canada, returning plastics to more sustainable manufacturing supply chains for use as feedstock for future products and packaging. Learn more about the Fund’s investment criteria and apply for funding here.

The Fund’s goal of optimizing recovery infrastructure is one part of Closed Loop Partners’ broader initiative of Advancing Circular Systems for Plastics. This initiative prioritizes scaling reuse and refill models and reducing material usage in design, while bolstering the recovery infrastructure to address plastics waste.

About Closed Loop Partners

Closed Loop Partners is a New York-based investment firm comprised of venture capital, growth equity, private equity, project-based finance and an innovation center focused on building the circular economy. The firm has built an ecosystem that connects entrepreneurs, industry experts, global consumer goods companies, retailers, financial institutions and municipalities, bridging gaps and fostering synergies to scale the circular economy.

About Sealed Air

Sealed Air (NYSE: SEE) is in business to protect, to solve critical packaging challenges, and to make our world better than we found it. Our packaging technology, solutions, and systems create a safer, more resilient and less wasteful global food supply chain, enable e-commerce, and protect goods transported worldwide.

Our globally recognized brands include CRYOVAC® brand food packaging, SEALED AIR® brand protective packaging, AUTOBAG® brand automated systems, BUBBLE WRAP® brand packaging, and SEE™ Automation solutions.

SEE’s Operating Model, along with industry-leading experts in materials, engineering, technology, and science are driving our innovative solution systems to be more sustainable, automated, and digitally connected.

SEE is leading the packaging industry to create a more environmentally, socially, and economically sustainable future and has pledged to design or advance 100% of its packaging materials to be recyclable or reusable by 2025, and a bolder goal to reach net-zero carbon emissions in its global operations by 2040.The company is also committed to a diverse workforce and inclusive culture through its 2025 Diversity, Equity and Inclusion pledge.

SEE generated $4.9 billion in sales in 2020 and has approximately 16,500 employees who serve customers in 117 countries/territories. To learn more, visit sealedair.com.

Disclaimer:

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Capital Management or any company in which Closed Loop Capital Management or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Closed Loop Capital Management does not utilize its website to provide investment or other advice, and nothing contained herein constitutes a comprehensive or complete statement of the matters discussed or the law relating thereto. Information provided reflects Closed Loop Capital Management’s views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision. Certain information on this Website may contain forward-looking statements, which are subject to risks and uncertainties and speak only as of the date on which they are made. The words “believe”, “expect”, “anticipate”, “optimistic”, “intend”, “aim”, “will” or similar expressions are intended to identify forward-looking statements. Closed Loop Capital Management undertakes no obligation to update publicly or revise any forward-looking statements, whether as a result of new information, future developments or otherwise. Past performance is not indicative of future results; no representation is being made that any investment or transaction will or is likely to achieve profits or losses similar to those achieved in the past, or that significant losses will be avoided.