4 Key Drivers Accelerating Resilient and Circular Supply Chains

May 13, 2020

COVID-19 has disrupted inertia around the existing linear system, forcing a re-evaluation of the status quo and highlighting the risks of opaque and global supply chains. The timeframe of transformation is unprecedented, happening in months rather than years. The current circumstances emphasize the need for a transition to a more resilient circular economy. This sentiment was echoed in our webinar this month on Trends in Circular Innovations for Resilient Supply Chains.

Panelists from seemingly unrelated fields: fashion, recycling/technology, and logistics identified four themes that resonate across industries, build resiliency to system shocks, like COVID-19, and propel the circular economy forward: transparency, localization, digitization and automation.

Fast Tracking Transparency

The movement towards a circular economy cannot be accomplished by one actor, one company, or even one industry. Therefore, transparency and collaboration are essential. This means data sharing within and across industries and thoughtful collaborations.

Opaque supply chains prohibit stakeholders from understanding where, how and when ingredients or products are sourced, in transit, at a store or where they go after use. Identifying these gaps creates opportunities to reduce waste and increase efficiencies; all foundational elements of a circular economy.

Ocean freight shipping is a USD 115 billion industry with significant environmental impacts. Reports note that shipping accounts for about 3.1% of the world’s greenhouse gas emissions annually. Our portfolio company, TradeLanes, is transforming the industry that operates behind the scenes to supply many of our products. They are enhancing transparency by providing an online platform that addresses inefficiencies, digitizing and managing trade execution for bulk shipping of commodities (e.g., meats, grains, paper, plastics).

By digitizing the process, TradeLanes enables greater transparency. Parties are able to ensure timely negotiations, delivery and tracking of products. This reduces unnecessary wastage from mismanaged or spoiled goods and reduces error rates for clients. For exporters still reliant on outdated paper filing systems (a shockingly large proportion of the industry today), COVID-19 is shining a spotlight on how a lack of transparency creates industry-wide problems as critical shipments are delayed, poorly routed or lost amidst the chaos. TradeLanes is just one example of an innovator disrupting an industry through increased transparency in a complex multi-stakeholder process.

From Global to Local

As global supply chains are disrupted and industries experience supply shortages as a result of COVID-19, localization becomes increasingly attractive. By bringing production closer to end markets, supply chains can be more resilient to system shocks. Much like the eat local movement, companies are looking to source, manufacture and produce closer to market. An ancillary benefit includes a reduced product carbon footprint. With mounting pressures for greater ESG disclosures from investors, corporates and the public, among others, more companies are recognizing that localizing their supply chains has multifold benefits.

In the United States, the world’s largest apparel market, 97% of clothing is made abroad. The path of one cotton t-shirt may be thousands of miles, with the cotton grown in India, milled in Mexico and sewn in South Africa. As awareness grows around the carbon footprint and resource intensity of the industry there is a growing movement to lessen the miles traveled. Our portfolio company, The Renewal Workshop, discussed how localization is built into their business model. Their team helps brands repair and resell clothing, keeping materials that would otherwise be landfilled in play. The Renewal Workshop showcased its agile business model as it was able to quickly source local materials and pivot to respond to the demand for gowns and other personal protective equipment during the pandemic. The team is distributing gowns to hospitals in their home state of Oregon, while continuing to provide repair services for their brand partners.

Automating for Efficiencies

Like other themes enabling the circular economy, automation plays an essential role in creating change. AMP Robotics CEO, Mantanya Horowitz, discusses how his company’s AI and robotics system improves the efficiency of materials recovery facilities (MRF). Their robotics system is rapidly learning to identify material types and “picking” them off the conveyor belts. With the adoption of automated recycling systems, facilities increase the accuracy and purity of sorted recyclables, and thereby improve the economics of the industry. Furthermore, when system shocks like COVID-19 span industries and require immediate change, like social distancing, robots give businesses the flexibility to adapt and reorient to new circumstances; in doing so, ensuring their employees health and safety. Automation can also enable staff to dedicate time to the most pressing responsibilities.

Doubling Down on Digital

Transparency, localization and automation could not be possible without the digitization of systems. Digitization closes the gaps in systems by providing accurate and real-time data on the location, availability and condition of materials. With unwavering agreement, our panelists remarked on how systems devoid of digitization are likely to lag in a transition to the circular economy.

As COVID-19 brings the world economy to a sudden and grinding halt, it highlights the existing pain points in our current system. There is no better time to reflect on the fragility of the linear model. Resiliency lies with a transition to the circular economy, an economy that is transparent, local, automated and digital.

Related posts

Blog Post

How AI Can Reduce Food Waste at Restaurants

Closed Loop Ventures Group led the seed investment...

Blog Post

Why We Invested in Mycocycle: Nature-Inspired Circular...

Closed Loop Partners’ Ventures Group saw a key opportunity...

Press Release

Closed Loop Partners Leads $4M Seed Round for LAIIER,...

Investment in the innovative liquid leak detection...

Blog Post

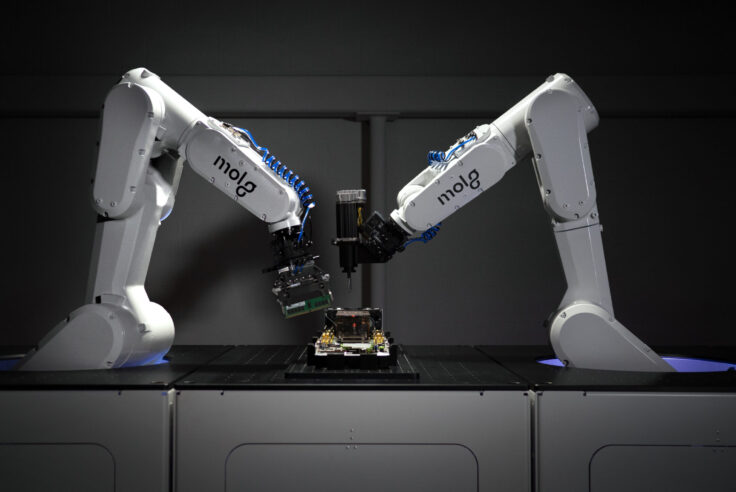

Making Circularity Stick: Electronics

A conversation with Rob Lawson-Shanks, CEO of Molg...

Press Release

Closed Loop Partners Doubles Down on Investment in...

Closed Loop Ventures Group joins Earthodic's $4 million...

Blog Post

Why We Invested in Neutreeno: Engineering Circular...

Neutreeno offers a game-changing solution that seamlessly...

Press Release

Molg Raises $5.5 Million in Seed Funding to Tackle...

Closed Loop Partners' Ventures Group leads seed funding...

Blog Post

How the Apparel Industry Is Challenging Us to Think...

The high cost of textile waste has sparked the need...

Blog Post

Why We Invested in Aerflo: Making Reuse an Everyday...

Closed Loop Ventures Group is thrilled to announce...

Blog Post

Why We Invested in Capra Biosciences: How Microbes...

Today, we are witness to a rapidly changing manufacturing...

Blog Post

Why We Invested in VALIS Insights: Bringing Circularity...

Closed Loop Partners invested in VALIS Insights because...

Blog Post

Why We Invested in Found Energy: The Importance of...

Closed Loop Ventures Group invests in Found Energy,...