3 Reasons Why Recycling is Good Business in America and a Key Driver of the Circular Economy

It’s Earth Day 2019 and it’s time to celebrate one of our best traditions: recycling. There’s a lot happening in our industry today: from new robots that sort recyclables to technologies transforming recycled plastics into valuable commodities. Other big themes to celebrate: opportunity and profit.

Last year, Closed Loop Partners, and firms that co-invested with us including Goldman Sachs, Citi, Google and Engie, invested over $210 million dollars in companies that are building a circular economy. The world’s largest consumer goods companies are on board too, many making public commitments to use recycled content ratios of up to 50% in their products.

Why? Because they see opportunity – and value. Natural resource extraction is expensive and landfills are unsustainable. As we shift towards a regenerative, circular economy and unlock the embodied $1 trillion value, we know that recycling is a crucial piece of the puzzle.

Today of all days, let’s take a minute to appreciate the true value of recycling in America – and let’s commit to keep going. Here’s what you need to know to celebrate recycling when talking to friends, family, and colleagues:

Recycling is Profitable: It’s good for taxpayers, municipalities, manufacturers, and investors

The recycling industry is an economic engine, providing over 500,000 jobs in America and creating more than $100 billion in revenue. The metal, paper, plastics, electronics, textiles and glass in the recycling stream are inherently valuable. While commodity markets do fluctuate, most of our waste still commands high prices, especially materials like PET, used in water bottles, which sold for $309 per ton, or clear HDPE, used in milk jugs, for $734 per ton, on average in 2018. Let’s think about the alternatives. If these materials end up in landfills, it’s taxpayers’ money that foots the bill. With a national average disposal cost of more than $50/ton, communities would have to pay over $3 billion annually in additional landfill disposal fees if these materials weren’t recycled.

Case in Point: Lakeshore Recycling Systems (LRS), Illinois. LRS serves greater Chicago and Northern Illinois, providing residential and commercial collection of recyclables, single stream recycling and construction and demolition processing services. LRS has been so successful in the past 5 years that Goldman Sachs is now their biggest investor. In their Heartland facility in 2018, they achieved revenues of approximately $65/ton and now they employ over 150 people. This best in class operation is the manufacturing feedstock for circular supply chains.

Recycling Reduces Costs & Volatility: That’s good for business

With scarce resources and increasingly volatile markets, many of the world’s largest corporations are shifting toward circular supply chains that are stable, protect the environment and reduce costs. In doing so, they avoid the volatile extraction costs embedded in manufacturing materials, like plastic. The demand for recycled materials is growing.

Case in Point: Public commitments by 37 major corporations. Thirty-seven of the world’s largest consumer brands and retailers, including Coca-Cola, Danone, Nestlé, PepsiCo, Unilever, Walmart, and others have made public commitments to use recycled plastics in their packaging within the next 10 years. Current projections indicate new real demand in North America of 5 million to 7.5 million metric tons annually by 2030. Even better? There are technologies transforming plastics waste into the building blocks for new materials that are ready to meet this demand. As these scale, a potential revenue opportunity of $120 billion in the U.S. and Canada awaits.

The Industry is Growing Here at Home: The opportunities are endless

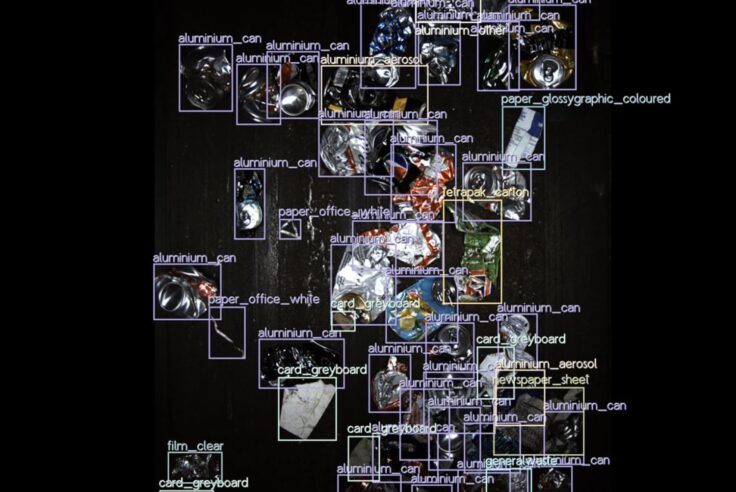

When China stopped importing foreign scrap, the recycling industry was shaken. Business as usual no longer sufficed. But this wasn’t an end to the industry, it was a wake-up call. It pushed us to invest in domestic infrastructure, process our own waste and deliver higher quality bales of recycled materials. Materials Recovery Facilities (MRFs) that were already doing this, like Eureka Recycling in Minnesota, were less vulnerable to China’s bans. The residual contamination rates of their operations are less than 8 percent and 90 percent of their recovered material goes to markets in the state, supporting regional growth. MRFs are now identifying opportunities to up their game and invest in new equipment and technologies to enhance their performance. Innovative companies like AMP Robotics are gaining traction; they use AI and robotic arms to effectively sort materials. More and more investment opportunities are materializing. Global companies like Nine Dragons, one of the largest paper manufacturers in China, are now investing hundreds of millions of dollars on recycling infrastructure in the US.

Case in Point: Pratt Industries, Georgia. Pratt Industries is the world’s largest, privately-held 100% recycled paper and packaging company, headquartered in Georgia. This year they’re opening a new paper mill outside of Columbus, Ohio, and also opened a paper mill in Indiana. They’ve also relocated some of their MRFs to larger facilities to accommodate high demand and have pledged to invest $2 billion in the company’s U.S corrugated box manufacturing. Pratt Industries also pays New York City for all of its recycled paper and cardboard in order to meet restaurants’ demand for pizza boxes made from these recycled materials. The City of New York generates revenue of approximately $15/ton for cardboard while reducing waste, landfill costs, and greenhouse gas emissions.

Our message this Earth Day? Keep recycling as a simple way to support a circular economy.

It’s good for the planet, it’s good for cities, and it’s good for business.

Learn more at: www.closedlooppartners.com

Related posts

Blog Post

How AI Can Reduce Food Waste at Restaurants

Closed Loop Ventures Group led the seed investment...

Press Release

New Data Reveals High Quantities of Food-Grade Polypropylene...

Closed Loop Partners’ Center for the Circular Economy...

Press Release

Closed Loop Partners and U.S. Plastics Pact Identify...

Packaging types primed for reuse lay the groundwork...

Blog Post

Why We Invested in Mycocycle: Nature-Inspired Circular...

Closed Loop Partners’ Ventures Group saw a key opportunity...

Press Release

Groundbreaking Results From Citywide Petaluma Reuse...

The Petaluma Reusable Cup Project from the NextGen...

Press Release

Closed Loop Partners’ Portfolio Company, Sage Sustainable...

The bolt-on acquisition scales Sage’s end-to-end...

Press Release

Closed Loop Partners Unveils Groundbreaking Findings...

Closed Loop Partners’ Center for the Circular Economy...

Press Release

Capricorn Investment Group Backs Closed Loop Partners...

The partnership signals tailwinds behind the circular...

Blog Post

8 Tips to Navigate Life Cycle Assessments for Circular...

Closed Loop Partners’ Center for the Circular Economy...

Press Release

Closed Loop Partners Leads $4M Seed Round for LAIIER,...

Investment in the innovative liquid leak detection...

Blog Post

The Key to a Strong Local Economy? It Must Be Circular.

4 ways the circular economy unlocks local value.

Blog Post

Why More Composters Are Recovering Food Scraps and...

Black Earth Compost and Glacial Ridge Composting Facility...